1. Introduction

Subsurface drainage refers to engineered systems designed to remove excess groundwater from soil below the surface. It plays a critical role in civil engineering, agriculture, and construction, ensuring the stability and functionality of infrastructure by preventing water accumulation that could compromise soil strength and material durability.

However, poor subsurface drainage can lead to serious challenges. Waterlogging in agricultural fields reduces crop productivity; in urban construction, soil erosion and foundation instability pose safety risks and drive up maintenance costs. Roads can crack, embankments may slip, and retaining walls could collapse under hydrostatic pressure.

To address these persistent issues, geocomposite strip drains have emerged as a modern, efficient alternative to traditional gravel-based drainage systems. Their modular design, improved flow capacity, and lower installation burden make them ideal for a wide range of applications.

2. What Are Geocomposite Strip Drains?

Geocomposite strip drains are prefabricated drainage systems consisting of a synthetic core wrapped in a geotextile filter fabric. These narrow, flexible drains are designed to intercept and convey groundwater away from critical structures.

Key Components:

Drainage Core: Often made from HDPE or other durable polymers, the core features a 3D mesh or dimpled profile that provides continuous pathways for water flow, even under soil pressure.

Geotextile Filter Layer: A nonwoven fabric encases the core to prevent soil intrusion while allowing water to pass freely, thereby reducing the risk of clogging and maintaining long-term performance.

Types of Strip Drains:

Wick Drains (Prefabricated Vertical Drains): Installed vertically to accelerate consolidation in soft soils by facilitating pore water escape.

Edge Drains: Commonly used in pavement and highway projects to intercept lateral water flow near the surface.

Panel Drains: Flat, wide strips used behind retaining walls and basement walls.

Each type is customized to meet the hydraulic and structural needs of the application.

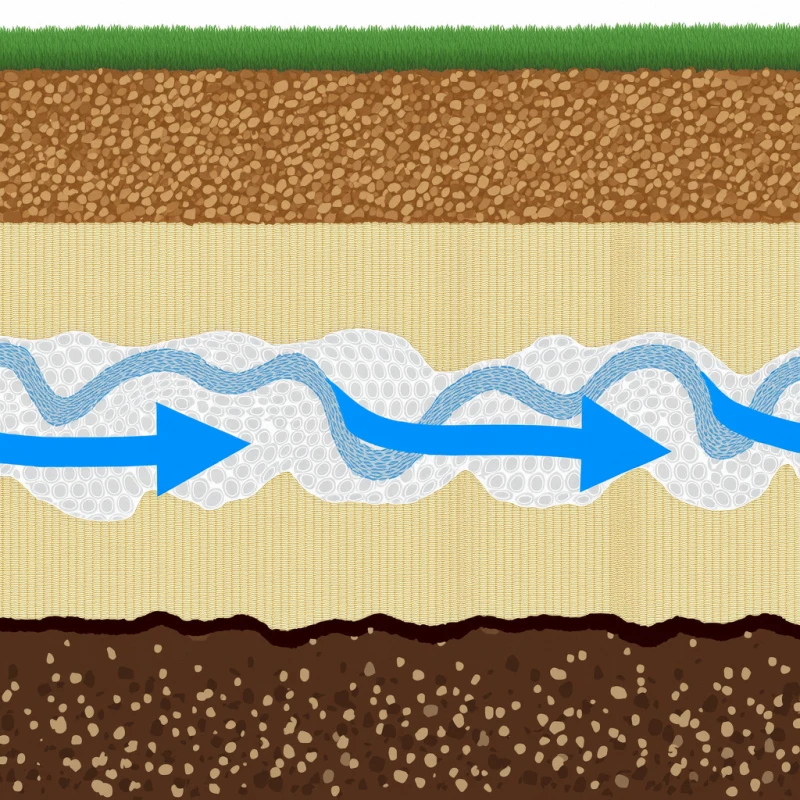

3. How They Enhance Subsurface Drainage

Mechanism of Action:

Geocomposite strip drains significantly outperform traditional gravel drains in terms of hydraulic conductivity and filtration performance.

High Flow Capacity: The engineered core structure provides uninterrupted flow channels, which facilitate faster water movement under load compared to the voids in gravel layers.

Clog Resistance: The surrounding geotextile acts as a selective barrier, filtering out soil particles while maintaining consistent flow, reducing maintenance demands.

Advantages Over Traditional Methods:

Space-Saving: Strip drains are typically 10–25 mm thick, occupying far less space than gravel trenches, which can exceed 300 mm.

Cost-Effective: They require less excavation, eliminate the need for large quantities of aggregate, and are faster to install—reducing labor and transportation costs.

Durability: Made from inert materials, geocomposite drains are resistant to biological growth, chemical attack, and physical collapse, ensuring long service life.

4. Key Applications

Geocomposite strip drains are used across industries where groundwater poses a risk to structural integrity, usability, or productivity.

Civil Engineering:

Roadways and Pavements: Prevent water infiltration into base layers, reducing freeze-thaw damage and rutting.

Retaining Walls: Relieve hydrostatic pressure behind the wall, improving stability and lifespan.

Bridge Abutments and Tunnels: Divert groundwater away from foundations and enclosed spaces.

Environmental Infrastructure:

Landfills: Integrated into leachate collection systems to comply with environmental regulations and prevent groundwater contamination.

Agriculture:

Improve root zone aeration and field workability, leading to higher crop yields and more efficient irrigation cycles.

Sports Fields and Parks:

Maintain turf stability and prevent standing water that can damage grass and disrupt usage.

5. Installation Best Practices

Proper installation is essential for maximizing the performance of geocomposite strip drains.

Step-by-Step Guide:

Site Preparation: Excavate and grade the trench or wall backfill area according to drainage plans.

Drain Placement: Position the strip drain vertically or horizontally, ensuring it is aligned with gravity flow for optimal drainage.

Outlet Connection: Connect the drain’s bottom or outlet end to a collection system (perforated pipe, gravel sump, or daylighted outlet).

Backfill and Compaction: Carefully backfill using compatible material and avoid sharp objects or excessive pressure that might damage the drain.

Common Mistakes to Avoid:

Incorrect Slope: Insufficient slope will impede water flow and reduce efficiency.

Inadequate Filter Selection: Using a filter with poor soil compatibility can lead to clogging or siltation.

6. Case Studies/Examples

Case Study 1: Highway Drainage – Hebei Province

In a highway construction project prone to seasonal flooding, Haoyang’s geocomposite strip drains replaced conventional gravel edge drains. The result: 40% faster installation, 30% reduction in cost, and a measured decrease in road base moisture content, extending pavement life by over 5 years.

Case Study 2: Landfill Leachate Control – Jiangsu

A large municipal landfill required a leachate collection system to meet national environmental protection standards (equivalent to EPA Subtitle D). Haoyang’s panel drains provided high flow rates and excellent chemical resistance, simplifying regulatory compliance and reducing environmental risk.

7. Environmental & Economic Benefits

Sustainability:

Geocomposite strip drains require fewer natural resources (no gravel or stone), produce less excavation waste, and are often recyclable.

Haoyang’s production facilities are certified to ISO 14001, ensuring sustainable manufacturing practices.

Return on Investment (ROI):

Lower material and labor costs during construction.

Reduced long-term maintenance, thanks to better clog resistance and longer system life.

Especially valuable in large infrastructure and agricultural drainage projects where scale multiplies savings.

8. Conclusion

Geocomposite strip drains represent a technological leap forward in subsurface water management. By addressing the limitations of traditional gravel systems—bulkiness, installation time, and maintenance—they offer a smarter, more sustainable alternative.

With proven benefits across civil engineering, agriculture, and environmental sectors, and supported by real-world success stories, Haoyang Environmental Co., Ltd. stands at the forefront of this evolution. Their advanced design, manufacturing capabilities, and commitment to quality make them a reliable partner in drainage innovation. If you have a project that requires cooperation, please contact Haoyang.

897.webp)

942.webp)

237.webp)