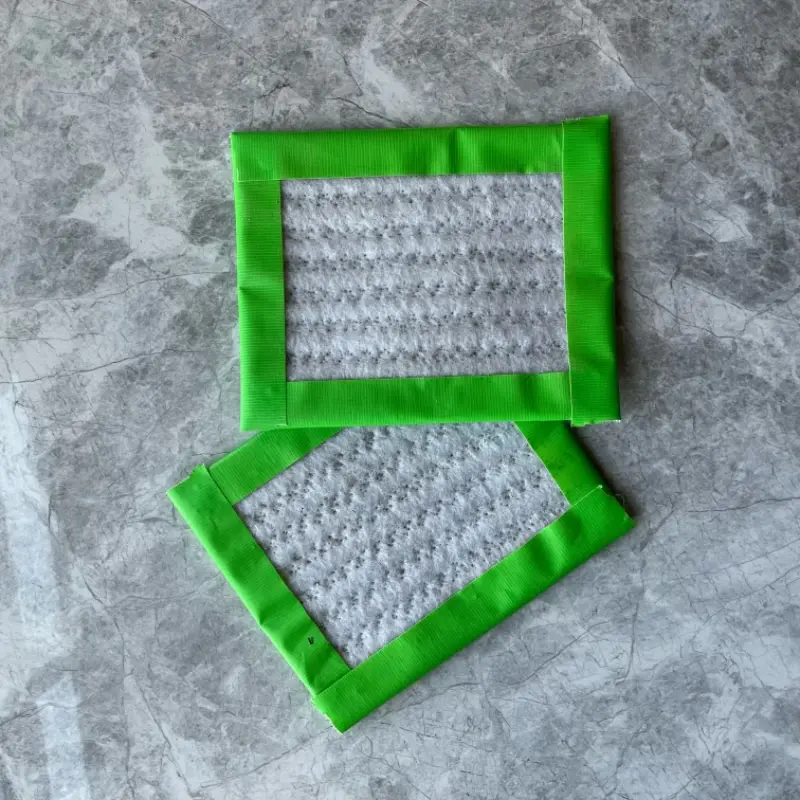

Material Analysis of Bentonite Waterproofing Blanket:

The waterproof blanket is composed of three materials: GCL (Geosynthetic Clay Liner) bentonite, PP woven fabric, and short fiber geotextile fabric. Through needle punching, the bentonite particles are fixed between the geotextile fabric and the plastic woven fabric to form a blanket-like waterproofing membrane. When the bentonite absorbs water, it expands to form a dense gel within the limited space between the upper and lower layers of non-woven fabric, thereby providing waterproofing. The waterproofing mechanism relies on the sodium-based bentonite particles in the blanket expanding more than 24 times when in contact with water, forming a uniform, highly viscous, and low-permeability gel system. Constrained by the two layers of geotextile fabric, the bentonite transitions from disorder to ordered expansion, resulting in the compacting of the bentonite layer and achieving waterproofing.

Advantages of Bentonite Waterproofing Blanket:

1,The waterproof blanket is resistant to aging during use, effectively combating biological degradation, and possesses self-healing capabilities.

2,The blanket exhibits excellent flexibility, adapting well to uneven settlement.

3,It is resistant to puncture and piercing, maintaining effectiveness even under freeze-thaw cycles and wet-dry conditions.

Specifications of Bentonite Waterproofing Blanket:

1,Gram weight options: 4000g, 5000g, 6000g

2,Width: 1-6m

3,Length: 20-30m (can be customized as per requirements)

4,Technical Parameters of Bentonite Waterproofing Blanket:

Unit area mass greater than 4000g

Bentonite expansion coefficient: 24mL/2g

Tensile strength: 600N/100mm

Peel strength: 40N/100mm

Permeability: 18mL

Bentonite durability: 20mL/2g

Requirements for Substrate Preparation for Bentonite Waterproofing Blanket Installation:

594334.webp)

1,The base should be compacted, smooth, free from puddles, stones, roots, or other sharp objects. Slopes should be leveled, compacted, and smooth to meet the required flatness for installing the waterproofing blanket. To ensure the effectiveness of the waterproofing blanket, the following points should be considered:

2,If there is water accumulation on the ground, drainage work should be carried out first. The compaction degree of the subsoil should not be less than 85%.

3,If there is moisture on the ground, drainage measures should be taken before installation to prevent early hydration of the waterproofing blanket.

4,Overlapping of the waterproofing blanket should be at least 15cm for the main part and 25cm for the edges, and it can be fixed with nails (or bamboo nails) and washers at 30cm intervals.

5,After the installation of the waterproofing blanket, construction personnel must prevent damage to the bentonite layer.

6,To prevent early hydration due to rainwater, a 3-5cm thick cement mortar should be laid after the cushion layer construction to prevent the waterproof layer from contacting water prematurely.

Weather Requirements during Installation:

1,The temperature should generally be above 10 degrees Celsius.

Wind speed should be below level 4.

2,Installation is not recommended in low temperatures, strong winds above level 4, or rainy or snowy weather.

3,In windy weather, sandbags should be used to secure the waterproofing blanket during installation.

Installation Method of Bentonite Waterproofing Blanket:

1,Installation can be done mechanically or manually, following the specified sequence and direction for sectioning and block-by-block installation.

2,When installing the waterproofing blanket, the joints between two blankets should be staggered to avoid continuous joints. There should be no impurities such as sand or water at the lap joints. Cutting can be done according to the construction dimensions, and installation can be either horizontal or vertical. When installing the waterproofing blanket, the joints only need to be overlapped, and dry bentonite powder (bentonite mud) should be sprinkled at a rate of 400 grams per square meter at the joints. If the joint width is greater than 30 cm, any defects or damage to the waterproofing blanket should be repaired promptly by covering with dry bentonite powder (bentonite mud) or by enlarging the damaged area by 15cm and applying GCL and dry bentonite powder (bentonite mud). The edges should be treated according to the lap joint requirements, and when the slope is steep, rivet nails can be used to prevent the waterproofing blanket from sliding.

Joint Method of Bentonite Waterproofing Blanket:

The width of the lap joint between two Bentonite Waterproofing Blankets is 30 cm. Bentonite powder and bentonite mud are used at the lap joint, with a quantity of 500 grams per meter for the horizontal lap joint and a mixture of bentonite powder and water for the vertical lap joint, replacing the bentonite powder.

Anchoring Method of Bentonite Waterproofing Blanket:

The groove anchoring method is recommended. The anchoring groove should be dug 40 cm away from the construction surface, with a width of 4 cm and a depth of 40 cm. The waterproofing blanket is pulled into the U-shaped groove and secured with sandbags or soil. When installing on vertical surfaces or slopes to prevent sliding, rivet nails with washers can be used for fixation. In addition to using steel nails to fix the overlapping parts and edges of the waterproofing blanket, nails should also be added to the middle of the entire waterproofing blanket as needed to ensure that the waterproofing blanket is securely installed on the wall and ground.

897.webp)

942.webp)

237.webp)