In recent years, with the increasing generation of solid waste, including industrial waste, household waste, commercial waste, and tourism waste, sanitary landfills have become one of the primary methods for the final disposal of urban garbage. In essence, a sanitary landfill involves placing solid waste on a well-laid anti-seepage liner, compacting it into thin layers of defined thickness, mechanically compressing, and covering it with layers of soil for disinfection. The choosing and treatment of materials for the anti-seepage system are the key focus of landfill design. Today we will talk about how to choose geosynthetic materials for landfill anti-seepage system.

Currently, some of the most effective anti-seepage liner materials used globally include:

High-Density Polyethylene Geomembrane (HDPE)

Widely used in sanitary landfills.

High-Density Polyethylene (HDPE) geomembrane is the most widely used geosynthetic material in sanitary landfills. It is a highly durable anti-seepage material produced by extruding or calendering high-molecular-weight polyethylene.

Key features include stable chemical properties, resistance to leachate from garbage, low permeability to prevent the penetration of groundwater and rainwater, containment of methane gas within the emission system, and stable resistance to ultraviolet (UV) radiation. The addition of carbon black in HDPE enhances its UV resistance, and it is free from plasticizers, addressing decomposition issues when exposed to UV radiation.

HDPE membranes come in two types: smooth and textured. Smooth surfaces are used at the base, while textured surfaces enhance anti-slip properties, addressing issues related to membrane adherence on landfill slopes and drainage layers. Traditional textured geomembranes are susceptible to nitrogen gas foaming techniques, resulting in a 50% loss of strength, creating a conflict between mechanical indicators and anti-slip functionality. Our factory now manufactures point-textured geomembranes, offering mechanical indicators equivalent to smooth-surfaced membranes while reinforcing anti-slip functionality—a promising material for landfill slope impermeability.

After covering with an HDPE membrane, an effective seal is formed, reducing foul odor emissions and controlling fly breeding. This HDPE membrane is double-sided, with one side in an eco-friendly green color, providing an aesthetically pleasing appearance and good visual effects while incorporating UV resistance functions.

Very Low-Density Polyethylene (VLDPE)

VLDPE geomembrane is a flexible liner material made from polyethylene resin, suitable for landfill closures on uneven surfaces.

Characteristics include multi-axial stretchability, making it suitable for uneven settlement and uneven ground.

Textured Geomembrane:

A textured geomembrane involves adding a layer of rough anti-seepage material to the surface of a geomembrane. This type of textured geomembrane is currently being promoted for widespread usage. Its primary characteristics include enhancing surface friction with soil, non-woven fabrics, and other synthetic fibers, improving adhesion with soil, cement, and other materials, and increasing anti-slip stability.

The maximum friction coefficient between the textured geomembrane and clay is as follows: at a friction angle of 29°, the shear force is 6.0 kPa, which is the highest friction coefficient with non-woven geotextiles. At a friction angle of 32°, the shear force is 2.2 kPa. Textured geomembranes are available in three thicknesses: 1.5mm, 2.0mm, and 2.5mm.

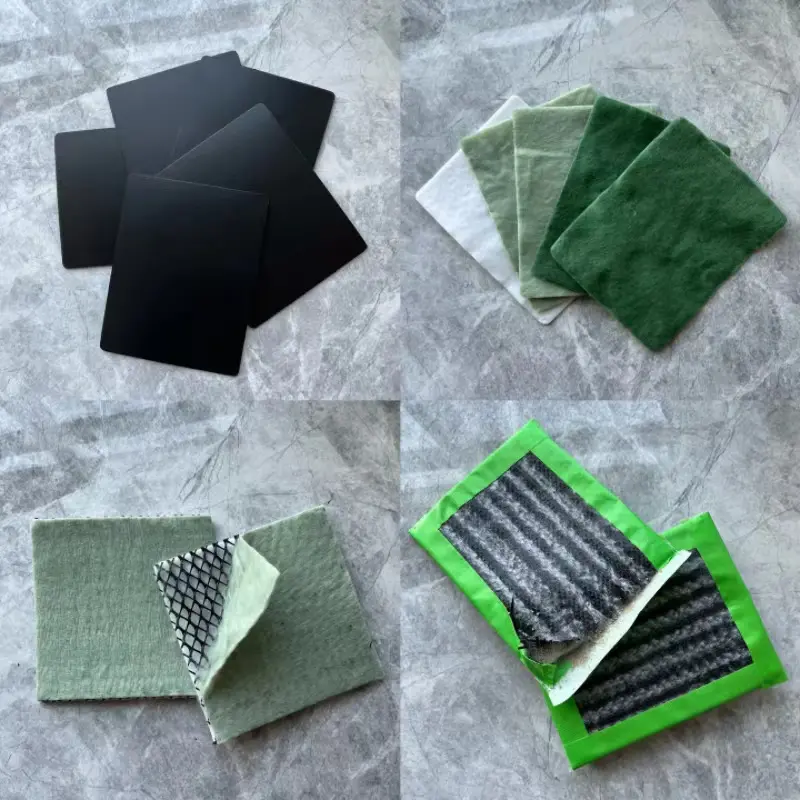

Geosynthetic Clay Liner (GCL)

Composed of bentonite clay sandwiched between or bonded to geotextiles or a geomembrane.

Widespread use in landfill applications, cooperating with geomembranes.

Exhibits high water absorption capacity, self-healing properties, permanent waterproofing effects, high strength, high elongation, corrosion resistance, and impact resistance.

Geosynthetic Clay Liner (GCL) is a composite material comprising bentonite clay sandwiched between or bonded to geotextiles or a geomembrane. It is one of the widely used anti-seepage materials in landfills both domestically and internationally, typically employed in collaboration with geotextiles or geomembranes. The key features of GCL include a water retention capacity of >8%, a unit mass per unit area of >4.5 g/m2, and a permeability coefficient of <1×10-9 cm/s.

GCL's remarkable characteristic lies in its ability to undergo a volume expansion of 13-16 times when subjected to the high-performance soil-water reaction. This unique property allows it to self-heal damaged areas and internal cracks up to 3mm. Additionally, GCL exhibits permanent waterproofing effects, high strength, high elongation, corrosion resistance, and impact resistance.

Non-Woven Geotextile

Essential material for landfill anti-seepage design and construction.

Categories include anti-aging polypropylene short-fiber needle-punched geotextiles, polyester short-fiber geotextiles, and long-fiber non-woven geotextiles.

Consideration for factors such as wind resistance, erosion resistance, acid and alkali resistance, and drainage performance favors the use of anti-aging polypropylene non-woven geotextiles.

Composite Drainage Net:

A composite drainage net is a geosynthetic material designed for drainage applications in various civil engineering and construction projects. It typically consists of a three-dimensional net core that provides structural support and is used in the following applications:

Underground Water Collection and Drainage Systems:

The composite drainage net facilitates the efficient collection and drainage of underground water, helping to manage water flow and prevent waterlogging in construction sites or other relevant areas.

Cover Gas Drainage Layers:

In landfill and gas management systems, composite drainage nets are employed in cover gas drainage layers to assist in the proper venting and management of gases generated beneath the surface.

Top Breakage Layers:

In certain construction scenarios, the composite drainage net may be utilized in top breakage layers to enhance drainage and prevent issues related to surface water accumulation.

The 3D net core of the composite drainage net provides structural integrity while allowing for effective water drainage. This type of geosynthetic material plays a crucial role in maintaining the stability and functionality of drainage systems in various engineering applications.

Issues with the Application of Geosynthetic Materials in Landfills

1.Construction Damage

According to investigations into landfill issues, 97.6% of leakage problems are attributed to mechanical construction damage. Therefore, strict adherence to standards during construction is crucial. Avoid large machinery rolling and unauthorized operations under bulldozer blades, especially when working on geomembranes. Strengthen protective measures and strictly follow construction standards.

2.Treatment of Specific Areas:

For steep slopes and areas with a significant slope angle, anchoring should be done at intervals of 6-10m, adding a platform. Use a double layer of bentonite geosynthetic clay liner or a double layer of geotextile for drainage layers. Avoid hanging in mid-air. Anchor points should undergo proper treatment to prevent compression damage to HDPE membrane weld points.

3.Mechanical Construction Damage:

After laying the geosynthetic membrane on the landfill base, mechanical construction is not allowed on the membrane's drainage layer. However, manual work is often slow, and lax site management may lead to mechanical construction, which is not allowed. Any damage to the membrane can have severe consequences. Adding an additional layer of composite drainage net or a root-resistant roll may be implemented. The composite drainage net should have a fabric thickness of over 400g. Reduce the thickness of the drainage layer of sand and gravel or use lightweight machinery to avoid damage caused by unauthorized operations.

In summary, geosynthetic materials play a crucial and irreplaceable role in sanitary landfill sites. However, there is a need to develop higher-performing materials to prevent mechanical damage, avoid clogging, resist settling, prevent landslides, and address construction in specific areas. This remains a challenge for research departments and manufacturing enterprises in the field of geosynthetic materials, with the hope of finding solutions soon.

During China's "Eleventh Five-Year Plan," the total planned investment in harmless treatment facilities for domestic waste was 75.46 billion RMB, providing ample development space in the geosynthetic materials field. As a research and production enterprise in geotechnical materials, Nanyang Huaxin Engineering Materials should intensify research efforts, create functional products, improve product quality, and make the necessary contributions to the country's solid waste treatment and the well-being of the people. The total investment, when converted to US dollars, is approximately 11.76 billion USD. If your business or project needs to use geosynthetic materials, please choose our company as your supplier.

897.webp)

942.webp)

237.webp)