Geotextile fabrics are categorized based on their primary functions and applications in civil engineering and construction projects. Each type of geotextile has its own set of characteristics, making it suitable for specific applications. The choice of geotextile depends on factors such as the intended function, site conditions, and project requirements.

Main types of geotextile fabrics

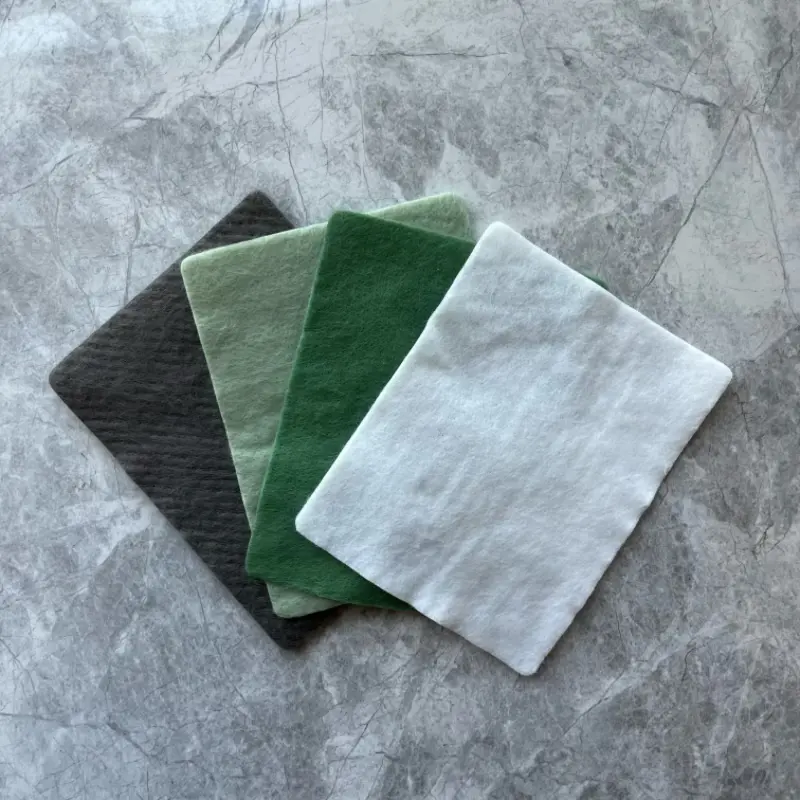

1, Non-Woven Geotextiles:

These are made by mechanically bonding or needle-punching fibers together. Non-woven geotextiles are commonly used for filtration, separation, and protection. They have good drainage properties and are available in various thicknesses. Products properties include:

a, Excellent filtration properties.

b, Good drainage capabilities.

c, Available in various thicknesses for versatility.

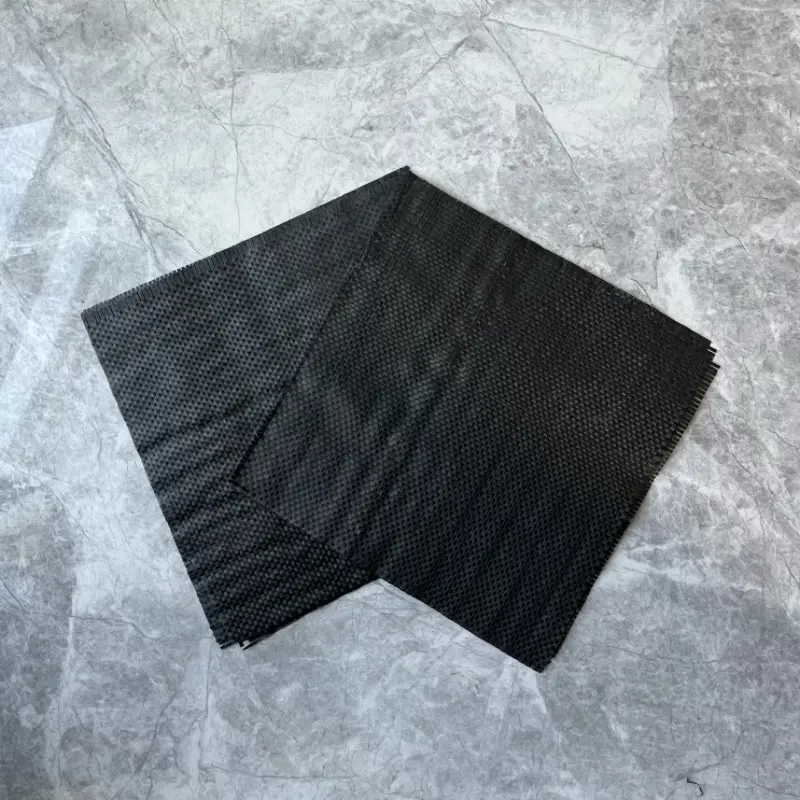

2, Woven geotextiles

Woven geotextiles are manufactured by weaving individual yarns together. They are known for their strength and stability. Woven geotextiles are often used in applications that require reinforcement, such as road stabilization and erosion control. Products properties include:

a, Manufactured by weaving individual yarns for strength.

b, High stability and load-bearing capacity.

c, Resistant to stretching and deformation.

3, Continuous Filament Geotextiles:

These geotextiles are made from continuous filaments of synthetic fibers. They are known for their high tensile strength and durability. Continuous filament geotextiles are often used in applications requiring reinforcement and stabilization. Products properties include:

a, Made from continuous filaments of synthetic fibers.

b, High tensile strength and durability.

c, Resistant to chemical degradation.

4, Short Fiber Geotextiles:

Short fiber geotextiles are made from chopped or staple fibers. These fibers are randomly oriented and then mechanically bonded to form a cohesive fabric. They are commonly used for filtration, separation, and protection. Products properties include:

1, Made from chopped or staple fibers.

2, Fibers are randomly oriented and mechanically bonded.

3, Cohesive fabric with moderate strength.

Main differences between them

1, Non-woven geotextiles are versatile with good filtration and separation properties.

2, Woven geotextiles offer high strength and stability, making them suitable for reinforcement.

3, Continuous filament geotextiles excel in tensile strength and durability, ideal for long-term stabilization.

4, Short fiber geotextiles provide moderate strength and are commonly used for filtration and protection.

Factors need to be considered when choosing the right geotextile fabrics

1, Functionality:

Filtration: If the geotextile is intended for filtration, choose a fabric with the appropriate opening size (geotextile opening size) to prevent soil particles from passing through while allowing water to flow.

Separation: For separation applications, the geotextile should prevent the mixing of different soil layers. Choose a fabric with sufficient strength to maintain separation.

2, Material Type:

Geotextiles can be made from various materials, including polypropylene, polyester, and polyethylene. The choice of material depends on factors like chemical resistance, durability, and the specific requirements of the project.

3, Weight and Thickness:

The weight and thickness of the geotextile are important considerations. Thicker and heavier fabrics are generally more durable and can provide better support. However, the specific requirements of your project will determine the appropriate weight and thickness.

4, Permeability:

Consider the permeability of the geotextile, which is the ability of water to pass through. Depending on the application, you may need a geotextile that allows water to flow through or one that acts as a barrier.

5, Strength and Durability:

Evaluate the strength characteristics of the geotextile, including tensile strength, puncture resistance, and tear strength. The fabric should be able to withstand the stresses and loads it will encounter in the specific application.

6, UV Resistance:

If the geotextile will be exposed to sunlight, consider its resistance to ultraviolet (UV) degradation. UV-resistant geotextiles are essential for applications where prolonged exposure to sunlight is expected.

7, Installation Conditions:

Consider the conditions under which the geotextile will be installed. Some fabrics are more suitable for specific installation methods or site conditions.

8, Cost:

Balance the performance requirements with the budget constraints of the project. While it's important to choose a geotextile that meets the project's needs, cost considerations are also significant.

9, Local Regulations and Standards:

Be aware of any local regulations or industry standards that may dictate the type of geotextile to be used in specific applications.

10, Manufacturer's Recommendations:

Follow the recommendations provided by the geotextile manufacturer. They often provide guidelines and specifications for the proper use of their products.

Each type of geotextile has its own set of characteristics, making it suitable for specific applications. The choice of geotextile depends on factors such as the intended function, site conditions, and project requirements. Consulting with a geotechnical engineer or other relevant professionals can help determine the most appropriate type of geotextile for a particular project. Haoyang invironmental is a leading geosynthetic products fatory with more than 15 years expirences, if you have any questions, fell free to contact Echo:

phone/whatsapp: 0086-16615773082 email: export@hygeosynthetics.com

897.webp)

942.webp)

237.webp)