Geomembrane, also known as geomembrane liner or impermeable membrane, is a type of synthetic material primarily used for waterproofing and anti-seepage in various engineering projects such as landfills, reservoirs, tunnels, and underground structures. Its production process requires precision and attention to detail to ensure the final product meets the required standards for durability, flexibility, and impermeability.

I. Raw Material Preparation and Formula Design

The primary raw material for geomembrane is polyethylene (PE), particularly high-density polyethylene (HDPE) and linear low-density polyethylene (LLDPE). These raw materials undergo preprocessing steps such as screening, cleaning, and drying before being fed into an extruder for melt extrusion. During raw material preparation, manufacturers will conduct formula design based on different application needs and performance requirements.

Formula design is a crucial step in geomembrane production. Besides the basic polyethylene raw material, additives such as antioxidants, UV stabilizers, and reinforcing agents can be added to improve the geomembrane's resistance to aging, UV rays, and mechanical strength. The types and quantities of these additives need to be precisely calculated and adjusted according to specific product performance requirements.

II. Production Processing

The production processing of geomembrane mainly consists of melt extrusion, molding, cooling, and cutting. Depending on the molding method, the production process of geomembrane can be divided into the blown film method and the cast film method (also known as the extrusion coating method).

1. Blown Film Method

The blown film method is one of the most commonly used methods in geomembrane production. The production process is as follows:

Melt Extrusion: The pretreated polyethylene raw material is fed into an extruder and melted into a continuous melt under high temperature and pressure. The temperature, pressure, and speed parameters of the extruder need to be adjusted according to different materials and thicknesses to ensure the quality and stability of the melt.

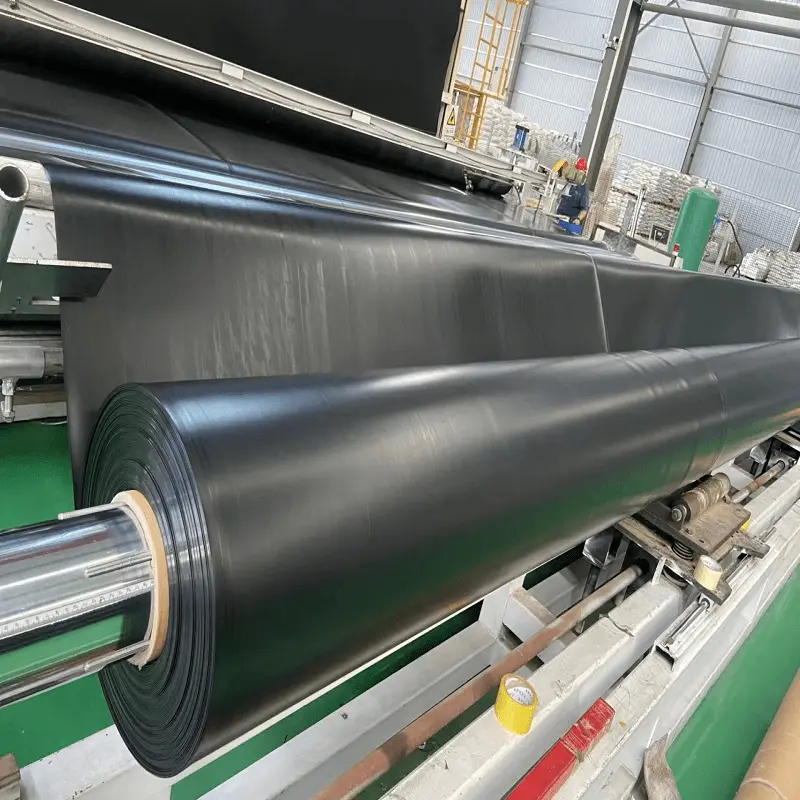

Blow Molding: After the melt forms a cylindrical shape at the extruder die, it is sealed into a membrane embryo through the introduction of a fixed frame. At this point, compressed air enters the interior of the membrane, causing the membrane embryo to expand into a bubble. The bubble is continuously conveyed to the guide roll and winding device by the traction roll, ultimately becoming the finished geomembrane.

Cooling and Cutting: The geomembrane produced by blow molding needs to be rapidly cooled through a cooling device to prevent deformation and sticking. After cooling, the geomembrane is cut into different widths and lengths according to customer requirements using a cutting machine.

2. Cast Film Method

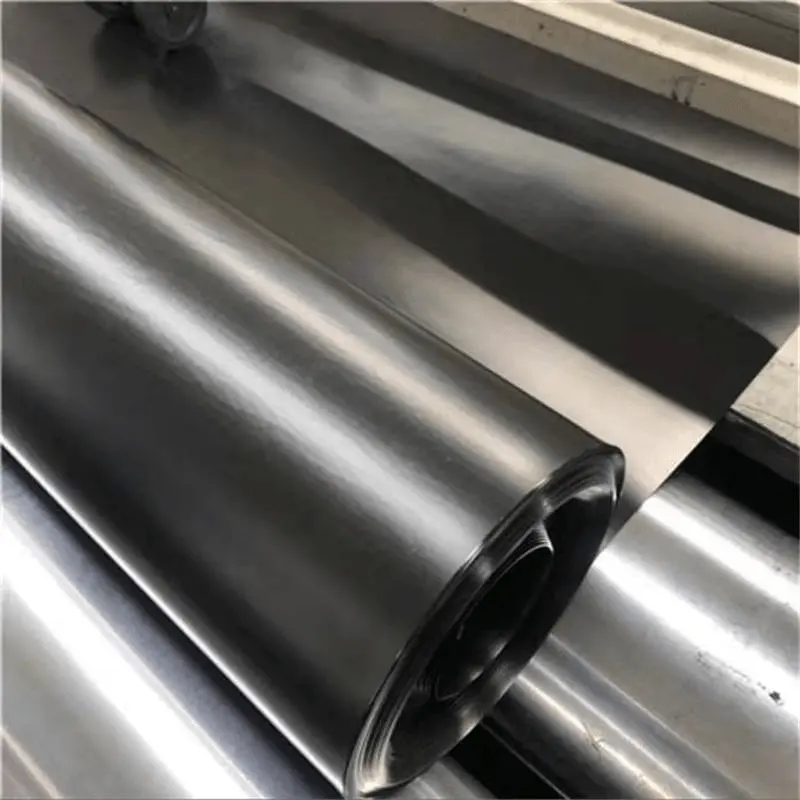

The cast film method produces a non-stretched, non-oriented dry-extruded film through melt extrusion and cooling. The production process is as follows:

Melt Extrusion: Similar to the blown film method, the pretreated polyethylene raw material is fed into an extruder for melt extrusion.

Cast Molding: After exiting the extruder die, the melt is cooled and formed on a cooling roll with a temperature-reducing agent. During this process, the melt rapidly solidifies into a film under the action of the cooling roll, forming a non-stretched, non-oriented dry-extruded film.

Cooling and Cutting: The geomembrane produced by the cast film method also requires cooling and cutting steps to ensure product dimensional stability and quality.

III. Quality Inspection and Packaging

After cutting, the geomembrane undergoes various tests, including thickness, tensile strength, elongation at break, tear strength, puncture resistance, and seepage prevention performance. These tests aim to ensure that the geomembrane meets relevant standards and customer requirements.

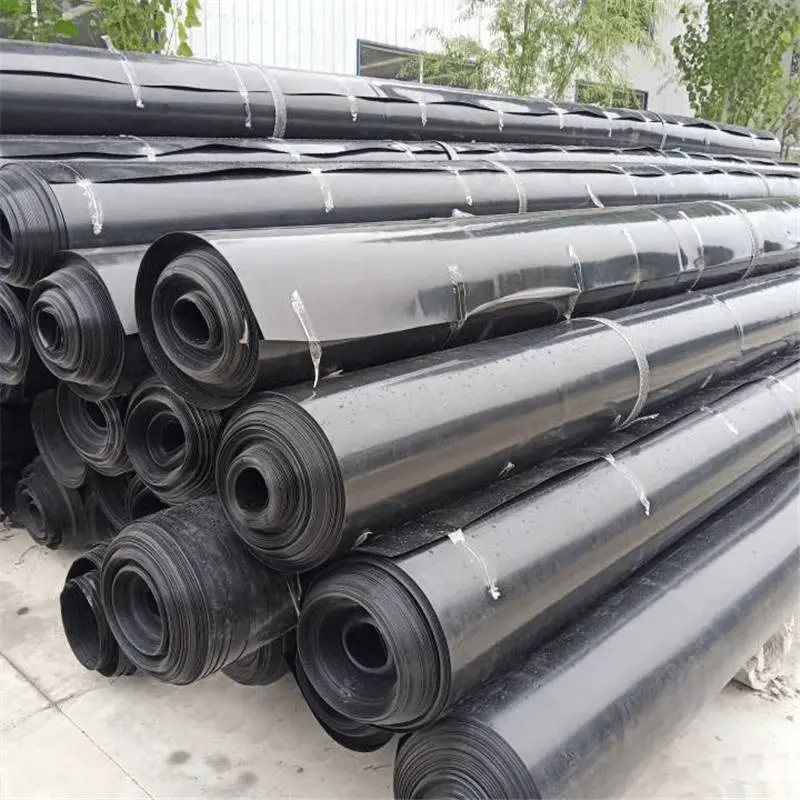

Geomembrane that meets the standards undergoes packaging. Packaging materials typically include waterproof and moisture-proof plastic films or paper bags to protect the geomembrane from damage during transportation and storage. During packaging, it is also necessary to protect the geomembrane surface from scratches or damage and ensure that the packaging is tight to prevent the geomembrane from moisture or fading.

IV. Recent Advancements in Production Technology

In recent years, geomembrane production technology has achieved significant advancements, primarily in material science, process innovation, and functional expansion.

1. Fiber Reinforcement Technology

By embedding high-strength, high-modulus fibers (such as polyester fibers, glass fibers, etc.) uniformly into the geomembrane matrix, a fiber-reinforced network structure is formed, significantly enhancing the geomembrane's tensile strength, tear resistance, and wear resistance. This reinforcement technology allows the geomembrane to maintain stable performance in complex terrains and harsh environments.

2. Application of Advanced Polymeric Materials

Introducing new polymeric materials as the main components of geomembrane, these materials exhibit excellent waterproofing, seepage prevention, corrosion resistance, and aging resistance properties. By optimizing material formulas and processing techniques, the overall performance of geomembrane can be further enhanced.

3. Multi-Layer Co-Extrusion Technology

Using multi-layer co-extrusion technology to produce geomembrane allows for precise control of the type, thickness, and performance of each layer, achieving multifunctionality and high performance for geomembrane. This technology can produce composite geomembrane with excellent waterproofing, seepage prevention, filtration, and drainage properties.

4. Surface Treatment Technology

Special treatments can be applied to the surface of geomembrane, such as coating with anti-slip layers, adhesive layers, or anti-aging layers, to improve the geomembrane's usability and durability. These treatment layers can enhance the adhesion between the geomembrane and soil, prevent moisture penetration, and protect against UV radiation.

5. Intelligent Applications

With the development of the Internet of Things and intelligent technology, geomembrane is also moving towards intelligent applications. By embedding sensors and monitoring devices within the geomembrane, real-time monitoring of its usage status, environmental changes, and engineering safety conditions can be achieved, providing a scientific basis for engineering management and maintenance.

V. Application Fields and Future Prospects

Geomembrane is widely used in water conservancy, environmental protection, construction, agricultural engineering, and transportation engineering due to its excellent properties. In water conservancy projects, geomembrane is mainly used for seepage prevention and waterproofing in reservoirs, hydropower stations, and dams. In environmental protection projects, it is used for seepage prevention and isolation in landfills and wastewater treatment plants. Additionally, geomembrane plays a crucial role in basements, swimming pools, irrigation channels, and other locations.

With technological advancements and increasing engineering demands, the production process and performance of geomembrane continue to upgrade and improve. In the future, geomembrane will become more environmentally friendly, efficient, and intelligent, providing more reliable technical support for various engineering projects. Meanwhile, with the emergence of new materials and processes, the application fields of geomembrane will continue to expand, making greater contributions to engineering construction and environmental protection.

In summary, the production process of geomembrane is a complex and precise one, with each step from raw material preparation to final inspection being crucial. Only by strictly controlling the production process and quality standards can high-quality geomembrane products be produced to meet the needs of various engineering projects. Haoyang Environmental rigorously oversees every step in the production process of geomembrane to ensure high quality products that cater to the specific needs of various projects. We are dedicated to meeting the diverse requirements of our clients across the globe. Welcome inquiries and orders from customers in all countries. We are committed to delivering excellence in geomembrane solutions.

![]() 1.5 Double-sided smooth HDPE geomembrane.pdf

1.5 Double-sided smooth HDPE geomembrane.pdf

![]() 1.5 Single-texture HDPE geomembrane.pdf

1.5 Single-texture HDPE geomembrane.pdf

942.webp)

237.webp)

106.webp)