Low-density polyethylene (LDPE) geomembrane is a geosynthetic material made of low-density polyethylene, mainly used in environmental protection and civil engineering fields. Compared with high-density polyethylene (HDPE) geomembrane, LDPE geomembrane has different performance characteristics, making it more advantageous in certain specific applications. The following is a detailed introduction to LDPE geomembrane, including its characteristics, applications, advantages, production process and usage methods.

1.Characteristics

Flexibility: LDPE geomembrane is softer than HDPE geomembrane and is suitable for applications that require higher flexibility.

Puncture resistance: It has good puncture resistance and is suitable for anti-seepage and protective purposes.

Chemical resistance: It has good tolerance to a variety of chemicals such as acids, alkalis and salts.

Low temperature resistance: It can still maintain flexibility and integrity in low temperature environments.

Easy to process: LDPE material is easy to process into various shapes and sizes and has strong adaptability.

Lower density: The lower density gives it advantages in certain applications, such as light weight and easy transportation and installation.

2.Technical parameters of environmentally friendly LDPE geomembrane(GB/T 17643-2011 GL-1)

No. | Item | Unit | Index | ||||||||

1 | Thickness | mm | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

2 | Density | g/cm3 | ≦0.939 | ||||||||

3 | Tensile breaking strength | N/mm | ≧6 | ≧9 | ≧14 | ≧19 | ≧23 | ≧28 | ≧37 | ≧47 | ≧56 |

4 | Break Elongation | % | ≧560 | ||||||||

5 | Right-angle Tearing strength | N | ≧27 | ≧45 | ≧63 | ≧90 | ≧108 | ≧135 | ≧180 | ≧225 | ≧270 |

6 | Puncture strength | N | ≧52 | ≧84 | ≧135 | ≧175 | ≧220 | ≧260 | ≧350 | ≧535 | ≧525 |

7 | Carbon black content | % | 2.0~3.0 | ||||||||

8 | Dispersion of carbon black | - | There is not more than one level 3 in 10 data, and level 4 and level 5 are not allowed to exist. | ||||||||

9 | Atmospheric Oxidation Induction Time (OIT) | - | ≧60 | ||||||||

10 | Low temperature impact embrittlement properties | - | Pass | ||||||||

11 | Water vapor permeability coefficient | g.cm/ (cm2.s.Pa) | ≦1.0*10-13 | ||||||||

12 | Dimensional stability | % | ±2.0

| ||||||||

Note | Technical performance indicators for thickness specifications not listed in the table are required to be performed by interpolation. | ||||||||||

3.Application

Landfill: Used as a liner in municipal, industrial and hazardous waste landfills to prevent pollutants from leaking.

Water seepage prevention: widely used in anti-seepage linings for ponds, reservoirs, artificial lakes and canals.

Agriculture: used for irrigation ponds, fish ponds and agricultural reservoirs to prevent water loss and improve water resource utilization efficiency.

Civil engineering: used for waterproofing layers of building foundations and underground structures to prevent water infiltration.

Tunnels and subways: used for waterproofing linings in tunnel and subway projects to provide long-term waterproof protection.

4.Advantages

Strong flexibility: The flexibility of LDPE geomembrane makes it easy to lay and adapt on complex terrain and irregular surfaces.

Easy to weld and repair: It can be connected by hot melt welding, and the seams are firm and easy to repair.

Convenient installation: Due to its light weight and flexibility, LDPE geomembrane is fast to install and has low labor intensity.

Low cost: Compared with some other geosynthetics, LDPE geomembrane has lower production and material costs.

Environmentally friendly: LDPE material is non-toxic, environmentally friendly, and suitable for environmentally friendly projects.

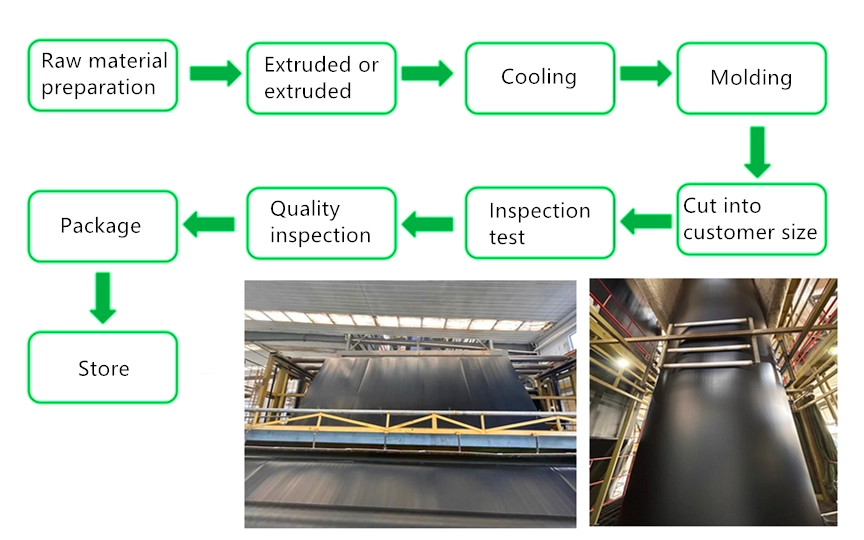

5.Production process

Resin preparation: Select high-quality low-density polyethylene resin and add appropriate stabilizers and additives.

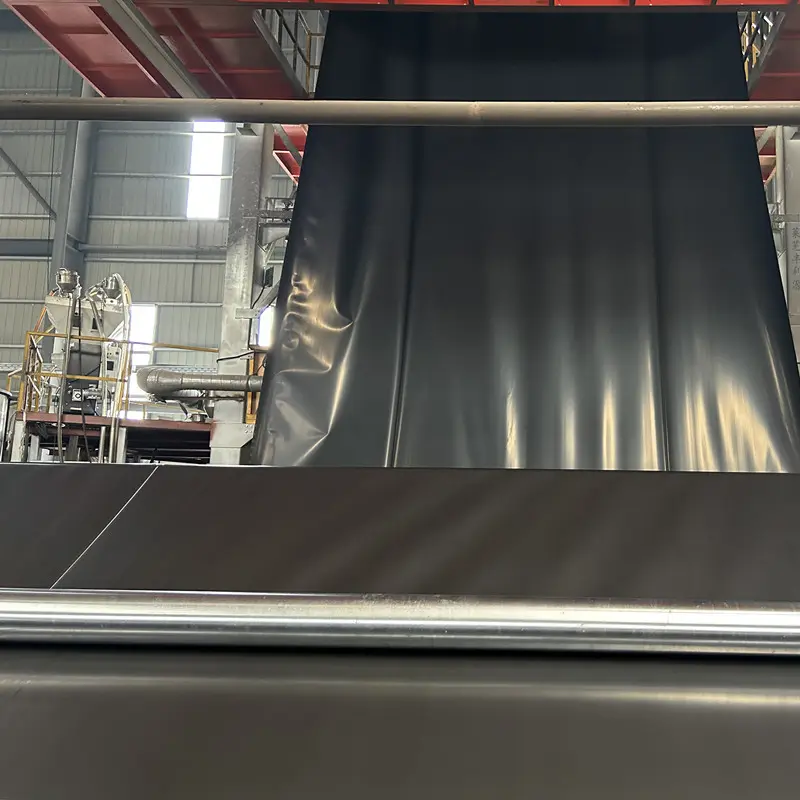

Extrusion: The resin mixture is melted at high temperature and extruded into a film through an extruder.

Cooling and shaping: The film is cooled by cooling rollers or water baths to shape it and reach the required thickness.

Winding and cutting: The film is wound into rolls or cut into specific sizes according to customer needs.

Quality inspection: Physical and chemical properties are tested to ensure that the product meets the standards.

6.How to use

Surface preparation: Remove debris, stones and sharp objects from the laying area to prevent puncturing the geomembrane.

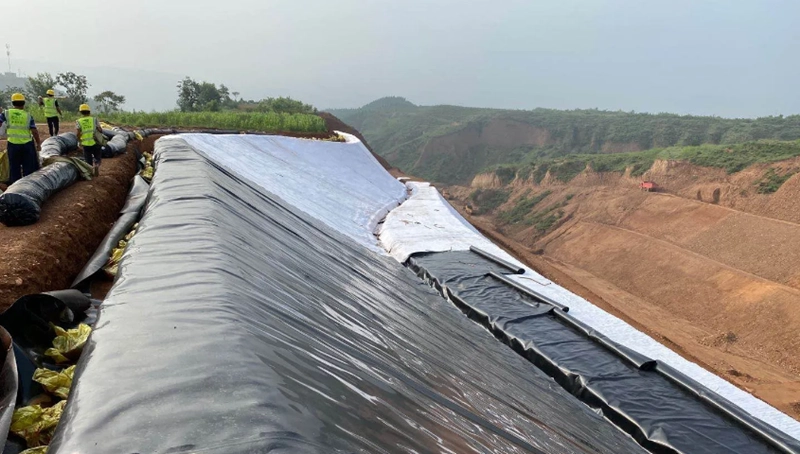

Laying and unfolding: Unfold and lay the LDPE geomembrane on the prepared surface to ensure flatness.

Welding seams: Use hot melt welding equipment to weld adjacent geomembrane sheets together to ensure that the seams are leak-proof.

Anchoring and fixing: Anchor the edge of the geomembrane in the trench, or fix it by other methods to prevent movement.

Inspection and testing: After installation, inspect the geomembrane to ensure that there is no damage and leakage.

7.Cost Control Methods

we must also reasonably control the cost of LDPE geomembrane and optimize costs. For example, in the procurement process, we can successfully reduce the cost of raw materials by negotiating prices with multiple suppliers and signing long-term supply agreements. At the same time, by optimizing the production process and reducing material waste in production, the overall production cost is reduced. During the construction process, by reasonably arranging the construction period and training construction personnel, the construction efficiency is improved, the construction period delays and the number of reworks are reduced, and the construction cost is further controlled. You can also choose a logistics company with low cost and high-quality service in the transportation link, and reduce transportation time and costs by reasonably planning the transportation route. In addition, invest appropriate costs in product packaging to ensure that the product is intact during transportation and reduce transportation damage and rework costs.

8.Conclusion

Low-density polyethylene (LDPE) geomembrane is a geosynthetic material with high flexibility, good puncture resistance and chemical resistance. It has a wide range of applications in environmental protection, agriculture, civil engineering. Reasonable selection and use of LDPE geomembrane can effectively improve the performance and service life of engineering projects. Haoyang specializes in the production and supply of high-quality LDPE geomembranes to customers worldwide. Our geomembranes are engineered for durability and efficiency, making them ideal for a wide range of applications, including environmental protection, water containment, and waste management. With a commitment to excellence and customer satisfaction, Haoyang provides reliable solutions that meet international standards. If you have more specific questions or need further help, please feel free to let me know.

Email:sale2@hygeosynthetics.com

Mobile:8616615773081

![]() 0.75 Double-sided smooth HDPE geomembrane.pdf

0.75 Double-sided smooth HDPE geomembrane.pdf

![]() 1mm Single-texture HDPE geomembrane.pdf

1mm Single-texture HDPE geomembrane.pdf

![]() 2mm Single-texture HDPE geomembrane.pdf

2mm Single-texture HDPE geomembrane.pdf

![]() 1 Double-sided smooth HDPE geomembrane.pdf

1 Double-sided smooth HDPE geomembrane.pdf

503.webp)

759.webp)

897.webp)

942.webp)

237.webp)