Geomembrane welding is a specialized process used in civil engineering and environmental projects to join geomembrane sheets together, creating a continuous barrier for containment applications such as lining landfills, ponds, reservoirs, and other structures. This welding process typically involves the use of heat, pressure, or a combination of both to create strong and durable seams that prevent the leakage of liquids or gases. Advanced welding techniques and equipment are employed to ensure precise and reliable joining of geomembrane materials, contributing to the integrity and long-term performance of containment systems. Here are some details about Geomembrane welding:

1. Definition: Geomembrane welding refers to the process of joining two or more Geomembrane sheets together to create a continuous, impermeable barrier. This process ensures the integrity and effectiveness of the Geomembrane liner to contain fluids, prevent leaks and protect the environment.

2. Types of Geomembrane welding technology:

(1) Hot wedge welding: In this technique, a heated wedge-shaped tool is used to melt and fuse Geomembrane sheets. The molten edges are pressed together to form a strong and continuous weld.

(2) Hot air welding: This technique involves using hot air to heat overlapping Geomembrane sheets. Once the material reaches the appropriate temperature, pressure is applied to fuse the sheets together.

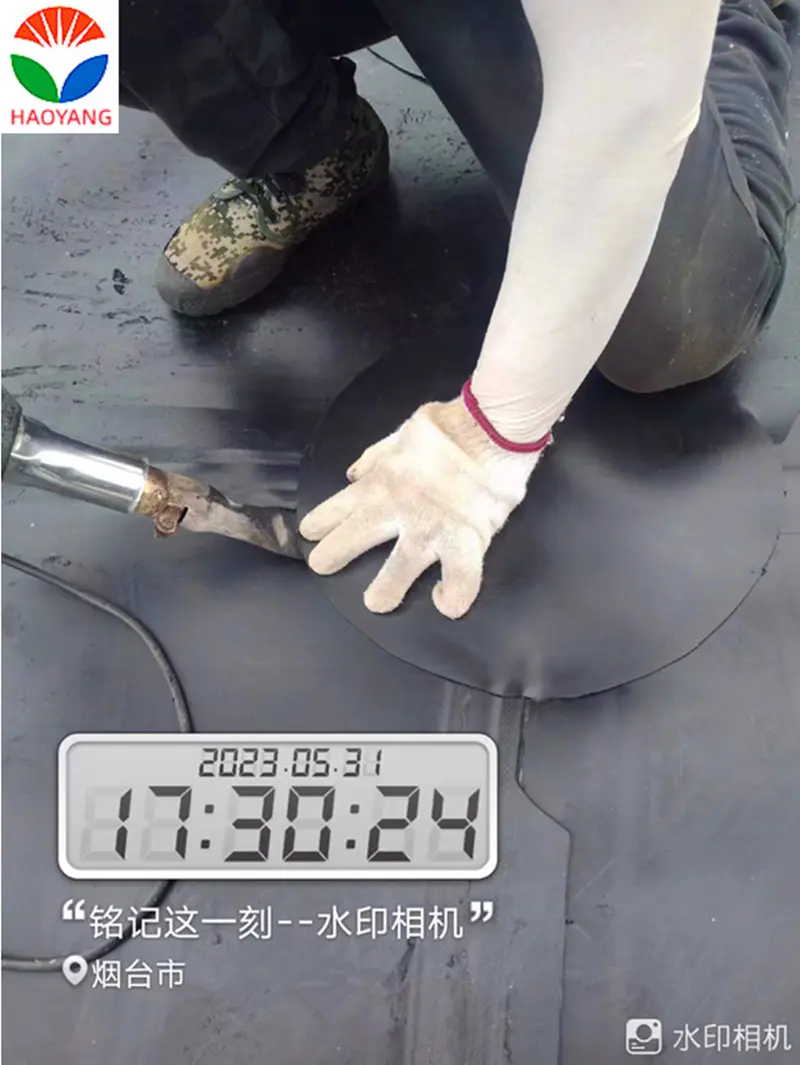

(3) Extrusion welding: Extrusion welding uses a special welding gun to melt and extrude the Geomembrane material between the connected sheets. After cooling, the extruded material forms a strong connection.

(4) Electrofusion welding: Electrofusion welding uses electric current to heat conductive wires or plates embedded in the Geomembrane. The heat generated melts the Geomembrane material, allowing the sheets to fuse.

3. Equipment and tools:

Geomembrane welding requires specialized equipment and tools, including welding machines, welding rods or tapes, heat guns, wedge welding machines and extrusion welding machines. These tools are critical to achieving correct weld quality and connection integrity.

Welding gun for geomembrane welding

4. Factors affecting welding quality:

(1) Temperature: The temperature of the welding equipment and Geomembrane materials must be carefully controlled to ensure proper fusion without overheating or burning the material.

(2) Pressure: Sufficient pressure must be applied during the welding process to ensure a strong bond and weld integrity.

(3) Speed: The speed at which the welding equipment moves along the weld seam will affect the welding quality. Proper speed control is critical to achieving consistent and even welds.

(4) Surface treatment: The welding surface must be clean, dry and free of impurities to ensure proper fusion and adhesion.

Welding rods for geomembrane welding: blue and white

Welding rods for geomembrane welding: black and white

5. Applications: Geomembrane welding is used in a variety of applications, including:

(1) Landfill: Geomembrane liners are installed in landfills to prevent leachate contamination and protect the surrounding environment.

(2) Mining: used to contain and manage wastewater, tailings and chemical solutions in mining operations.

(3) Water and wastewater treatment: Used in reservoirs, ponds and tanks to prevent leakage and infiltration.

(4) Environmental remediation: used in hazardous waste storage, groundwater protection and soil remediation projects.

(5) Quality Assurance and Testing: Welded Geomembrane welds undergo rigorous quality assurance testing to ensure the integrity and performance of the weld. Commonly used non-destructive testing methods include visual inspection, vacuum testing and destructive testing.

Overall, Geomembrane welding is a critical process in Geomembrane installation that requires skilled technicians, appropriate equipment and compliance with industry standards and best practices to achieve a reliable and effective isolation system.

897.webp)

942.webp)

237.webp)