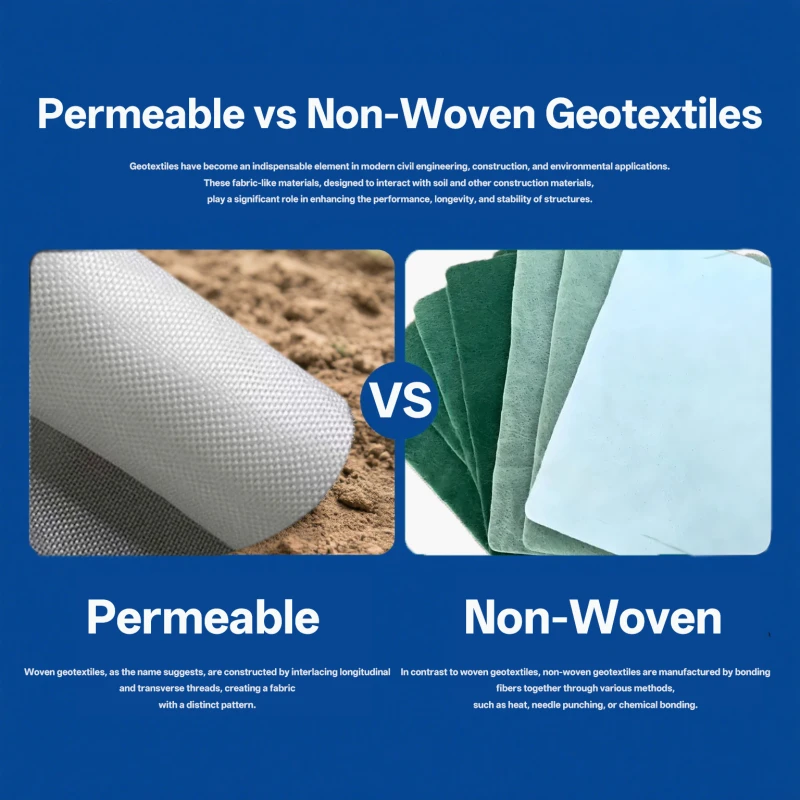

Geotextiles have become an indispensable element in modern civil engineering, construction, and environmental applications. These fabric-like materials, designed to interact with soil and other construction materials, play a significant role in enhancing the performance, longevity, and stability of structures. Among the various types of geotextiles, permeable (woven) and non-woven geotextiles are the most commonly used. Despite their similar function in separating, reinforcing, and filtering soil, these two types of geotextiles have distinct differences in their structure, performance, and application.

In this article, we will explore how permeable and non-woven geotextiles work, their unique characteristics, and the conditions in which each type excels. Additionally, we will examine related research data, provide comparative analysis, and highlight the importance of selecting the right type of geotextile for different engineering projects. Haoyang Environmental Co., Ltd., a leader in geosynthetic material research and manufacturing, offers top-tier geotextiles designed to meet the evolving demands of the global construction and environmental industries.

Understanding Geotextiles

Before diving into the specific comparison of permeable and non-woven geotextiles, it’s important to understand what geotextiles are and the fundamental role they play in construction and environmental engineering.

Geotextiles are synthetic fabrics used in geotechnical and civil engineering projects for filtration, reinforcement, separation, and drainage. These materials are made from polymers such as polypropylene or polyester, and their performance largely depends on their manufacturing method, which can either create a woven or non-woven structure.

Woven Geotextiles: These are made by interlacing two sets of yarns in a grid-like pattern, resulting in a strong fabric that offers excellent tensile strength and stability. Woven geotextiles are generally more durable and are best suited for projects that require reinforcement, such as roads and pavements.

Non-Woven Geotextiles: These are created by bonding fibers together through heat, pressure, or chemical processes, rather than weaving them. As a result, non-woven geotextiles have a more porous structure, making them ideal for filtration, drainage, and erosion control.

How Permeable Woven Geotextiles Work

Woven geotextiles, as the name suggests, are constructed by interlacing longitudinal and transverse threads, creating a fabric with a distinct pattern. These materials are designed to have low permeability, meaning they resist water flow to some extent. However, woven geotextiles are often used in applications that require filtration or separation in conjunction with soil, where the prevention of large particles from passing through is critical.

Key Features:

Reinforcement and Stabilization: Woven geotextiles are typically used to reinforce weak soils or to stabilize the ground in construction applications. Their high tensile strength allows them to support loads and prevent soil displacement.

Durability: The woven structure gives these materials high durability and resistance to mechanical damage. They can withstand significant pressure and are less prone to tearing compared to non-woven geotextiles.

Limited Drainage Capability: Due to the tightness of the weave, woven geotextiles have lower permeability, which may limit their use in applications where drainage is a priority.

Applications of Woven Geotextiles:

Road and railway construction (as reinforcement material)

Stabilizing embankments

Reinforcing slopes and retaining walls

Construction of foundations and pavements

Performance Data for Woven Geotextiles:

| Property | Woven Geotextile | Test Method |

|---|---|---|

| Tensile Strength | 30 kN/m | ASTM D4632 |

| Pore Size | 0.1 - 0.5 mm | ASTM D4751 |

| Water Permeability | 15 - 100 L/m²·s | ASTM D4491 |

| UV Resistance | 70% (after 5000 hours) | ASTM D4355 |

| Durability | High | Various Standards |

How Non-Woven Geotextiles Work

In contrast to woven geotextiles, non-woven geotextiles are manufactured by bonding fibers together through various methods, such as heat, needle punching, or chemical bonding. This creates a felt-like material that is highly permeable and porous, allowing water to pass through while retaining fine soil particles.

Key Features:

Filtration and Drainage: The primary advantage of non-woven geotextiles lies in their ability to filter water and allow drainage. They are commonly used in systems where water needs to be filtered or diverted, such as drainage systems, landfills, and road construction.

Flexibility: Non-woven geotextiles are typically more flexible than woven ones, allowing them to conform to complex shapes and varying terrain. This makes them ideal for projects requiring erosion control and soil stabilization.

Lower Tensile Strength: While non-woven geotextiles excel in drainage and filtration, they generally offer less tensile strength than woven geotextiles, making them unsuitable for applications that require heavy load-bearing capabilities.

Applications of Non-Woven Geotextiles:

Drainage and filtration in road and railway construction

Erosion control in slopes and embankments

Landfills and waste containment

Soil separation in agricultural and landscaping projects

Performance Data for Non-Woven Geotextiles:

| Property | Non-Woven Geotextile | Test Method |

|---|---|---|

| Tensile Strength | 10 kN/m | ASTM D4632 |

| Pore Size | 0.3 - 1.0 mm | ASTM D4751 |

| Water Permeability | 50 - 500 L/m²·s | ASTM D4491 |

| UV Resistance | 50% (after 5000 hours) | ASTM D4355 |

| Durability | Moderate | Various Standards |

Comparison: Permeable vs. Non-Woven Geotextiles

While both permeable (woven) and non-woven geotextiles are essential in modern construction, they serve different purposes based on their physical properties. Below is a comparative analysis that can guide professionals in selecting the right type for their projects.

| Feature | Woven Geotextiles | Non-Woven Geotextiles |

|---|---|---|

| Tensile Strength | High | Moderate to Low |

| Water Permeability | Low to Moderate | High |

| Primary Function | Reinforcement, Separation | Filtration, Drainage |

| Durability | High | Moderate to High |

| Flexibility | Low | High |

| Applications | Roads, Embankments | Drainage, Erosion Control, Landfills |

| Cost | Moderate | Low to Moderate |

Selecting the Right Type of Geotextile

Choosing between permeable (woven) and non-woven geotextiles depends largely on the specific requirements of the project at hand. Factors like soil type, expected loads, drainage needs, and environmental conditions should be considered carefully before making a decision.

For projects that involve reinforcement and require high tensile strength, woven geotextiles are the preferred choice. They are ideal for road construction, embankments, and areas subjected to heavy loads.

On the other hand, if the project involves drainage, filtration, or erosion control, non-woven geotextiles offer superior performance. Their high permeability and flexibility make them well-suited for applications in waste containment, landfills, and drainage systems.

Haoyang Environmental Co., Ltd.'s Geotextile Solutions

At Haoyang Environmental Co., Ltd., we pride ourselves on our comprehensive range of geosynthetic materials, including both woven and non-woven geotextiles. Our products are designed to meet the highest standards of quality, ensuring optimal performance in a wide array of environmental and construction applications. With over a decade of expertise and innovation, we provide tailored solutions for geotechnical projects, including soil stabilization, filtration, drainage, and reinforcement.

As a certified leader in geosynthetics, Haoyang’s products are rigorously tested for durability, strength, and environmental resistance. Our non-woven and woven geotextiles undergo strict quality control measures to ensure they meet the unique needs of every project.

Conclusion

In the realm of civil engineering and environmental management, choosing the right geotextile is crucial for the success and longevity of a project. Understanding the differences between permeable woven and non-woven geotextiles, and their respective advantages, allows engineers and construction professionals to make informed decisions based on their specific needs.

Whether you require high-strength reinforcement or efficient drainage and filtration, Haoyang Environmental Co., Ltd. offers a wide variety of geotextile solutions to meet your requirements. As an industry leader, we continue to push the boundaries of geosynthetic material innovation to ensure sustainable and efficient outcomes for our clients.

If you have a project that requires cooperation, please contact us.

897.webp)

942.webp)

237.webp)