1、Product introduction

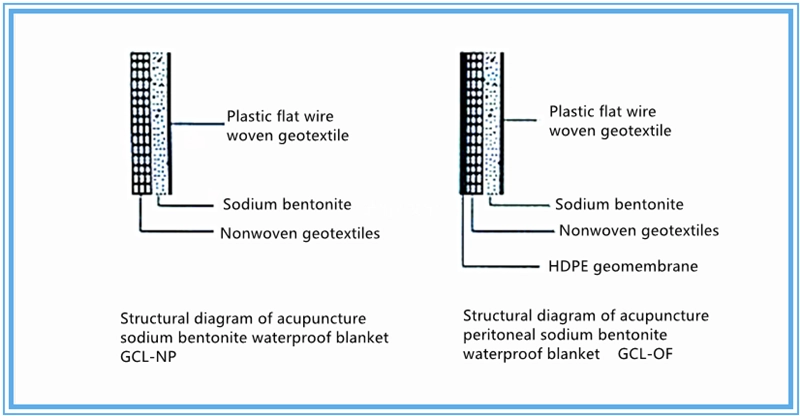

Sodium bentonite composite waterproof blanket (GCL) is a new type of geosynthetic material, which can be specially used for impermeable geosynthetic materials such as artificial lake water feature, landfill, underground garage, roof garden, pool, oil depot and chemical plant. The high expansion sodium bentonite is filled between the composite plastic flat silk geotextile and non-woven fabric, and the bentonite particles can not flow unidirectional by acupuncture method, and a uniform and high density rubber waterproof layer is formed in the pad when it meets water to effectively prevent water leakage. Bentonite waterproof blanket not only has all the characteristics of geotechnical materials, but also has excellent waterproof (seepage) performance. It is a kind of impermeable lining between GCL and polymer material (geomembrane).

The waterproof mechanism is that the sodium-based granule bentonite used in the bentonite waterproof blanket expands more than 24 times when it meets water, thus forming a uniform colloidal system, which has the characteristics of high viscosity and low filtration. Under the constraint of two layers of geotextile, bentonite expanded from disorder to order. The result of continuous expansion of water is that the bentonite layer itself becomes dense, thus having a waterproof effect.

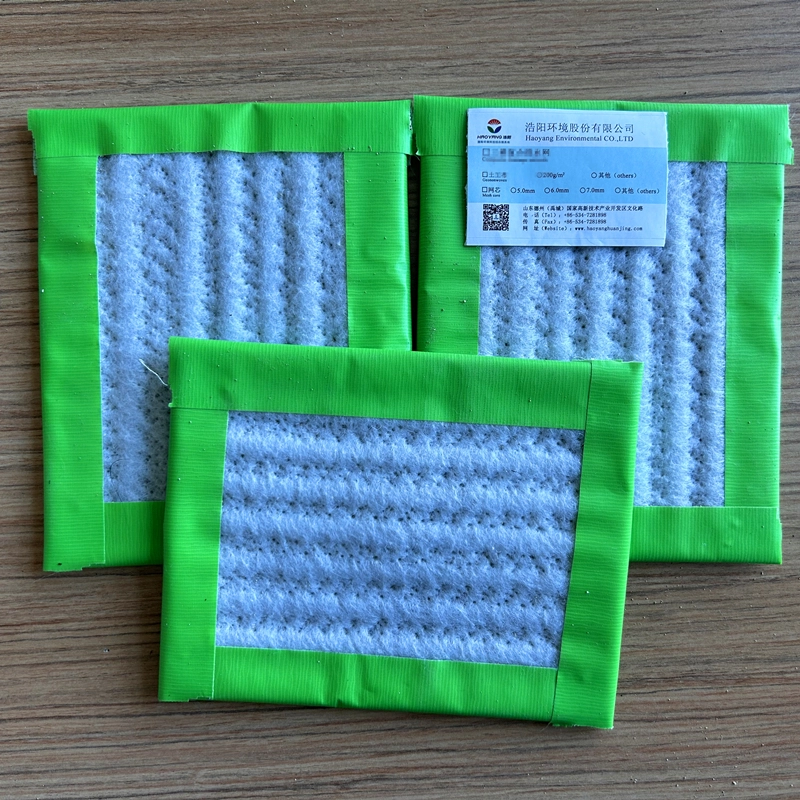

Our company mainly produces needled sodium-based swelling moisturizing waterproof blanket and needled coated sodium-based swelling moisturizing waterproof blanket.

2、How is sodium bentonite waterproof blanket produced?

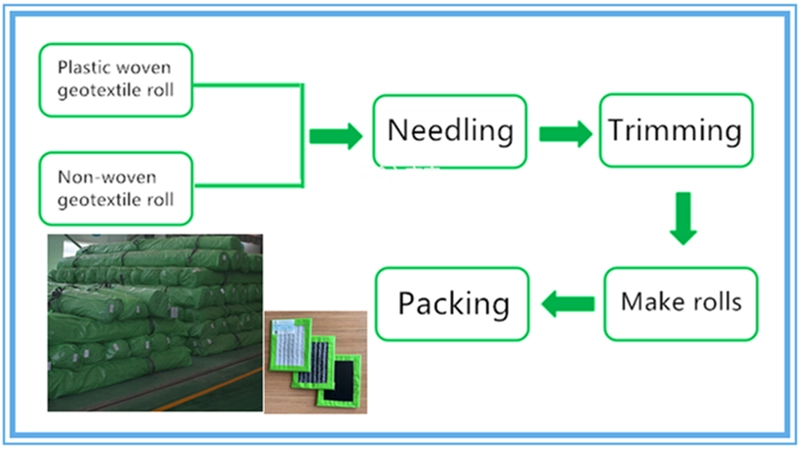

Production Process:

Specific operating procedures:

(1) Prepare the woven fabric and non-woven fabric in advance, put them in your position, and let the woven fabric and non-woven fabric two layers pass through the acupuncture part;

(2) Prepare the bentonite to the feed bucket, and transport the bentonite to the horizontal conveyor by the angled cage to control the feeding speed;

(3) The bentonite flow rate is adjusted by adjusting the position of the lower plate and cylinder;

(4) The needling machine thrusting and pulling the three through the hook barbed needle at a high speed to become a body intertwined with each other, in which the spindle and the net roller linkage drive, the barbed waterproof blanket transported to the next process;

(5) Cut the GCL waterproof blanket vertically and horizontally and roll it, adjust the meter to make it reach the length and automatically cross cut and check the package.

3、Bentonite waterproof blanket Physical properties:

Comparison of the national standard of physical and mechanical properties of sodium bentonite waterproof blanket by in-needling method and by needling coating method. It conforms to the national standard JG/T 193-2006 issued by the Ministry of Construction of China.

No. | Item | Unit | Index | ||

GCL-NP | GCL-OF | ||||

1 | Bentonite waterproof blanket weight per unit area | g/m2 | ≧4000 and ≧RV | ≧4000 and ≧RV | |

2 | Bentonite expansion index | ml/2g | ≧24 | ≧24 | |

3 | Blue absorption capacity | g/100g | ≧30 | ≧30 | |

4 | Tensile strength | N/10mm | ≧600 | ≧700 | |

5 | Elongation under maximum load | % | ≧10 | ≧10 | |

6 | Peel strength | Nonwovens and woven fabrics | N/100mm | ≧40 | ≧40 |

7 | PE film and nonwovens | - | ≧30 | ||

8 | Permeability coefficient | m/s | ≦5.0*10-11 | ≦5.0*10-12 | |

9 | Hydrostatic pressure resistance | - | 0.4MPa,1h, NO leakage | 0.6MPa,1h, NO leakage | |

10 | Filtration loss | ml | ≦18 | ≦18 | |

11 | Bentonite durability | ml/2g | ≧20 | ≧20 | |

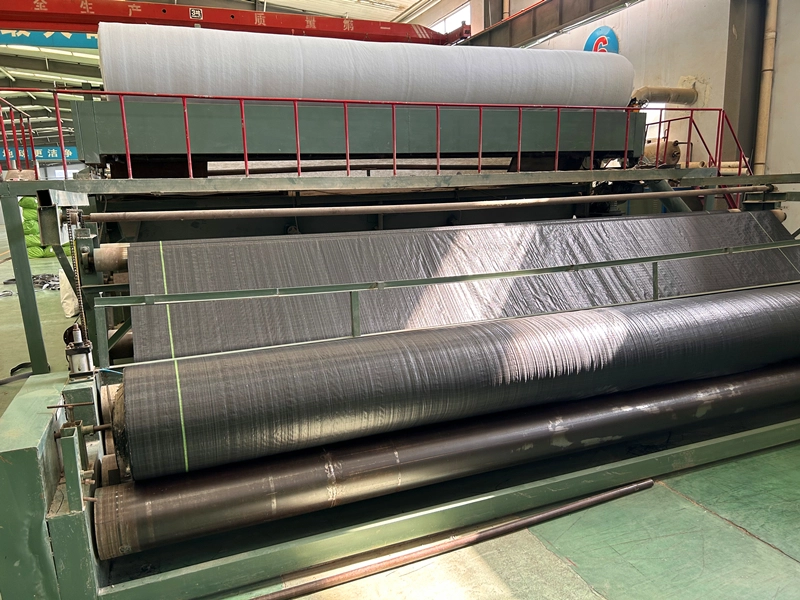

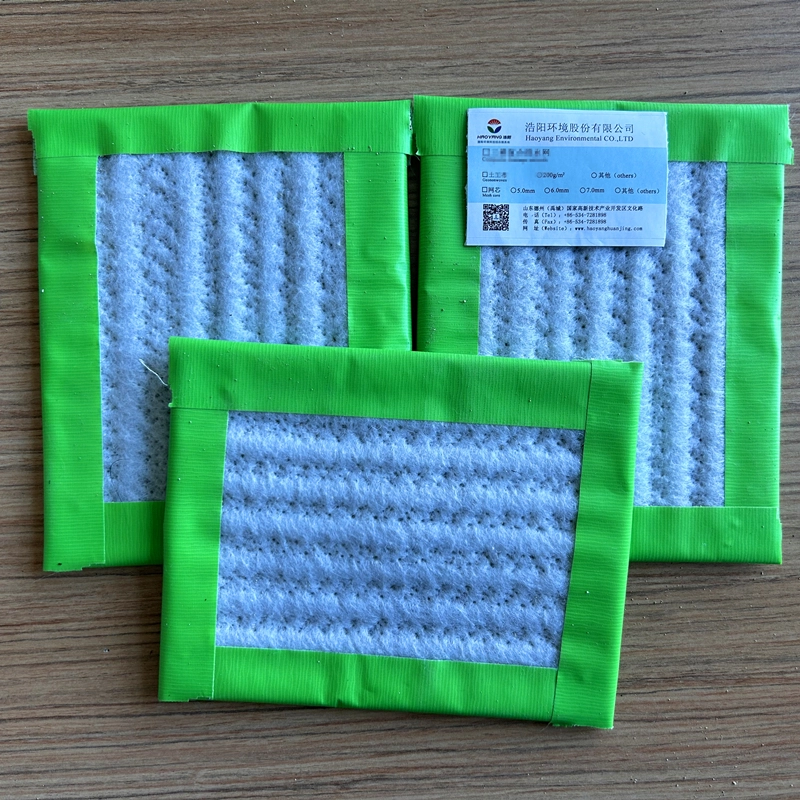

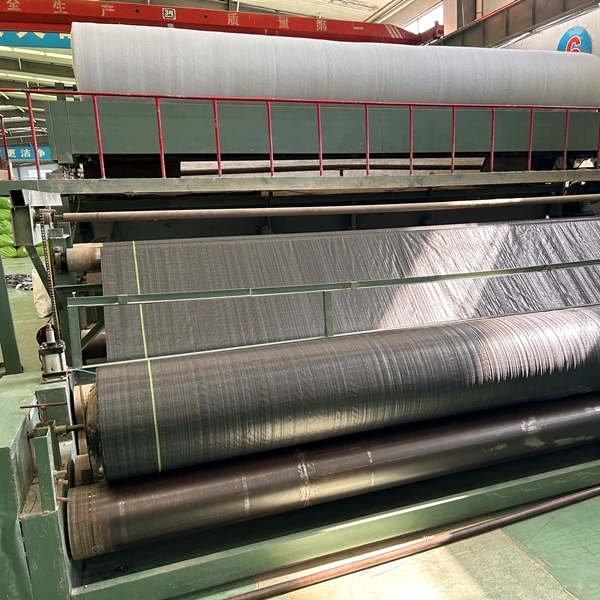

4、Production workshop

Welcome to our advanced production workshop! This is the center of precision manufacturing in our company. The following are some pictures of our advanced production equipment and high-quality products, as well as the workshop pictures implemented in accordance with the 6S standard: the equipment floor is clean, the product equipment is placed reasonably, and the ground line is clear and clear.

These pictures show our company's production equipment and some of our products, demonstrating our advanced production process and precision manufacturing capabilities.

5、Bentonite waterproof blanket construction requirements:

(1) The base should be checked before the construction of the bentonite waterproof blanket, and the base should be compacted and smooth, no pit water, no stone roots and other sharp objects.

(2) Bentonite waterproof blanket in the handling and construction process to avoid vibration and impact as far as possible, to avoid the blanket body has a large curvature, it is best to be in place.

(3) After the installation and acceptance of GCL, backfill work should be carried out as soon as possible. If it is used with HDPE geomembrane, the geomembrane should be welded in time to prevent it from being wet or broken by rain.

6、Bentonite waterproof blanket for finished protection:

(1) After the bentonite waterproof blanket is laid, geomembrane should be laid in time to avoid the erosion of wind and rain;

(2) After the bentonite waterproof blanket is laid, if the geomembrane cannot be laid in time, it should be covered with colored strip cloth or film to avoid weathering the wind and rain;

(3) After the bentonite waterproof blanket is laid, the vehicle rolling and other foreign body damage should be avoided;

(4) After the completion of construction, there shall be no mud, dirt, debris and other foreign bodies that may damage the impermeable layer on the bentonite mat.

(5) The bentonite waterproof blanket (GCL) roll should be stacked in a flat place without water accumulation, the height of the pile does not exceed four rolls, and the identification plate of the roll can be seen.

(6) Damage to bentonite waterproof blanket (GCL) caused by improper storage and operation is not allowed to be used in this project.

(7) The bentonite waterproof blanket (GCL) roll shall be protected from damage during transportation (including on-site transportation from the material storage place to the work).

(8) Physical damage to the bentonite waterproof blanket (GCL) roll must be repaired, severely damaged bentonite mat (GCL) can not be used, we will be removed from the site and replaced.

(9) Any bentonite (GCL) material that comes into contact with the leaking chemical solvent shall, at the discretion of the Supervising Engineer, not be allowed to be used on the project.

(10) If the bentonite blanket is damaged (torn, punctured, etc.) during installation, it can be repaired by cutting a "patch" from a new roll of bentonite blanket over the damaged area. The length of the four sides of the patch should not be less than 300mm from the damaged area, and some granular bentonite or bentonite slurry should be scattered around the damaged area before placing the "patch". If necessary, some adhesive can also be used to prevent the "patch" from shifting, or a small bentonite blanket can be placed under the broken area.

7、Mode of transport

We provide our customers with a variety of transportation methods for remote delivery of geomaterials, ensuring that products reach their destinations safely and quickly. Our range of transport options includes land, sea and air transport to meet the different needs and project requirements of our customers.

8、FAQ

Q1: Where is your factory located? How do I get there?

A1: Our factory is located in Yucheng High-tech Development Zone, Dezhou City, Shandong Province. You can take a plane to Jinan Yaoqiang International Airport, and then we will pick you up.

Q2: What is the lead time?

A2: Usually 5-10 working days after receiving the deposit.

Q3: How do you guarantee the quality testing of your products?

A3: The testing center of Haoyang Environmental Co., Ltd. obtained the CNAS Laboratory accreditation Certificate, certificate number L11088. Each batch of products will undergo rigorous testing before leaving the factory.

Q4: Is bentonite waterproof blanket suitable for basement, tunnel and other different structures? How does it work in different soil conditions?

A4: Our products are suitable for underground structures, including basements, tunnels, etc., and have good adaptability under different soil and environmental conditions.

Q5: Does product installation require special technology or equipment? Are there construction guides and video tutorials?

A5: We provide detailed construction guidelines and can provide construction videos, which is relatively easy to install and requires no special technology or equipment.

Q6: What about product quality control and packaging details? Is there a product warranty?

A6: We strictly implement the quality control process, product packaging meets the transportation needs, and provide product warranty period.

503.webp)

759.webp)

927.webp)

109.webp)