There are many classifications of geotextiles. Short-filament nonwoven geotextiles and filament nonwoven geotextiles are two types of geotextiles. They are very close in color and feel. Many people have difficulty distinguishing them. Here we will introduce them to you from several aspects. Let’s take a look at the characteristics of filament geotextiles and short fiber nonwoven geotextiles and their specific differences:

1. Introduction to filament nonwoven geotextiles and short filament nonwoven geotextiles

(1) Filament nonwoven geotextile:

Filament nonwoven geotextile is polyester filament spunbond needle-punched non-woven geotextile. It is an environmentally friendly geotechnical construction material produced from polyester raw materials through a series of processes. It can replace traditional engineering materials and construction methods, make construction safer, contribute to environmental protection, and solve basic problems in engineering construction more economically and effectively.

(2) Short filament nonwoven geotextile:

Short filament nonwoven geotextile is also called short fiber nonwoven geotextile. It is made of polyester curly short fibers with a fiber density of 6-12 denier and a length of 54-64mm.

2. The difference between short-fiber nonwoven geotextiles and long-filament nonwoven geotextiles

(1) In appearance

In terms of appearance, it is difficult to distinguish between filament nonwoven geotextiles and short fiber nonwoven geotextiles. The appearance color of filament nonwoven geotextiles is generally white, and the appearance color of short fiber nonwoven geotextiles is also white. However, if you look closely, you will find filament spunbond needles. The appearance color of thorn geotextile is white and somewhat shiny, while the white color of short fiber geotextile is slightly dull.

(2) In terms of material

Filament spunbond needle-punched geotextiles are generally made of polyester raw materials, short-fiber nonwoven geotextiles are generally made of polyester or polypropylene short fibers with a fiber content of 6-12 denier, so filament spunbond needle-punched geotextiles are the same The strength, elongation, bursting and other parameters of the specifications are better than short-filament nonwoven geotextiles.

(3) Applicable standards

The applicable standard for filament spun clay textiles is GBT17639-2008

The applicable standard for short-fiber nonwoven geotextiles is GBT17638-2017

(4) In terms of production technology

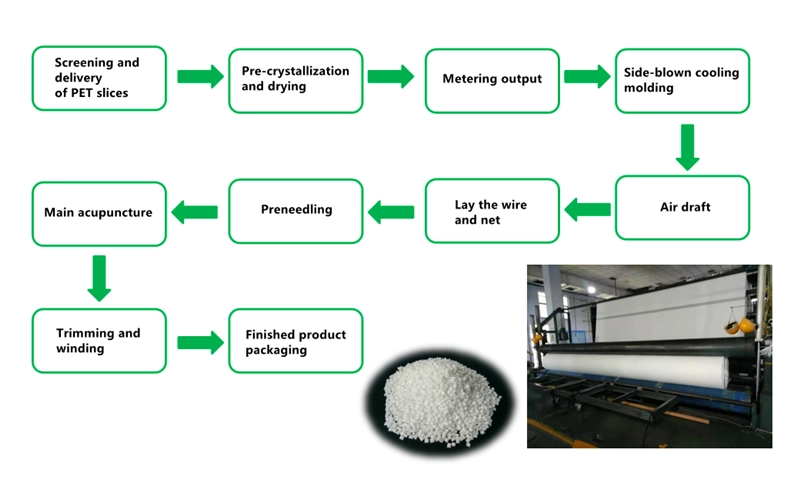

The production process of filament spun clay textiles mainly includes raw material screening, extrusion and melting, cooling, web laying, needle punching, reeling, cutting, packaging, etc.;

Production process diagram of filament nonwoven geotextile

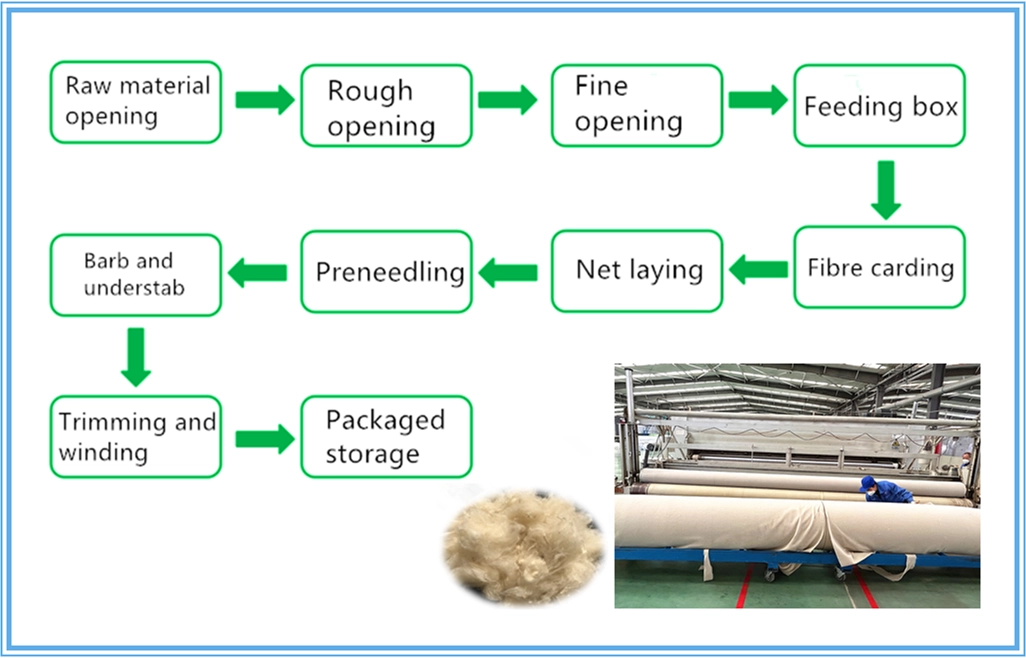

The production process of short fiber geotextiles mainly includes material selection, opening, fiber carding, netting, needle punching, reeling, cutting, packaging, etc.;

Production process diagram of short fiber non-woven geotextiles

Due to differences in fiber length and manufacturing process, the performance and application of the two geotextiles are also different, and the selection needs to be based on specific engineering requirements.

(5) In terms of characteristics

Fiber Length: Filament spun clay is made from long fibers and has a longer fiber length. Staple fiber geotextiles are made of short fibers or short filaments with shorter fiber lengths.

Strength and stability: Filament spun clay has high tensile strength and stability due to its longer fibers. Short fiber geotextile has relatively low strength and stability due to its short fibers.

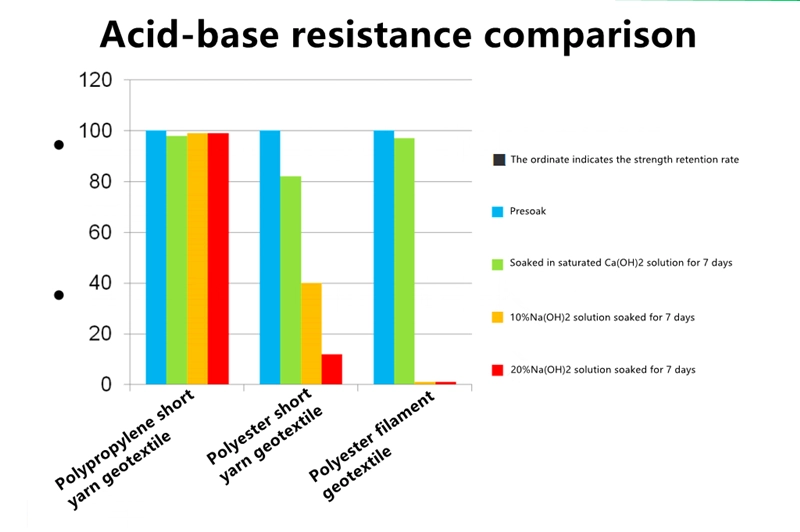

Comparison of acid and alkali resistance between filament non-woven geotextile and short fiber non-woven geotextile

(6) In application fields

(a) Filament spun clay fabric is suitable for projects with higher soil requirements, such as soil reinforcement and soil anti-seepage.

Roadbed reinforcement and soil reinforcement: Used for the reinforcement of roadbeds such as highways and railways, which can effectively stabilize the roadbed structure and reduce subsidence.

Geotechnical engineering and water conservancy engineering: used in bank protection, river regulation, dam anti-seepage and other projects to provide effective anti-seepage and reinforcement functions.

Environmental protection: As a soil protective layer, it is used in environmental protection projects such as land restoration and solid waste site coverage.

Construction engineering: Used in foundation reinforcement, impermeable layer construction and other construction projects to protect the structural stability of the building.

(b) Staple fiber geotextile is suitable for occasions that require high filtration and isolation performance, such as soil protection and soil and water conservation.

Reinforcement and reinforcement: Reinforcement is generally divided into two types: macro-reinforcement and micro-reinforcement. The reinforcement of geotextile belongs to the field of macro-reinforcement. Although short-filament nonwoven geotextile also has reinforcement function, its mechanical function is relatively small. , so it has certain limitations when used for reinforcement.

Filtration and drainage: Short-filament nonwoven geotextiles mainly replace the traditional material gravel layer in terms of filtration and drainage. The drainage capacity of the geotextile is directly proportional to the thickness of the geotextile. Generally speaking, the thicker the thickness, the greater the drainage capacity of the geotextile. The better. Composite drainage nets composed of short fiber geotextiles and drainage nets are widely used in the field of filtration and drainage. This is also the main function of short fiber geotextiles.

Barrier: Short-filament nonwoven geotextiles can separate two materials with different particle sizes, thereby ensuring the stability of the structure. However, the load that short-filament geotextiles can bear as a barrier layer cannot be too large.

Protection: Short-filament nonwoven geotextiles are widely used in protection projects, such as slope protection, urban greening, and prevention of road cracks.

The following is the product link of Haoyang Environment's specific filament non-woven geotextile and short fiber non-woven geotextile. You can click for reference.

Filament non-woven waterproofing reinforced drainage geotextiles

Multi-purpose soil management tool of staple fiber needled non-woven geotextile

![]() 200g Staple fiber non-woven geotextile.pdf

200g Staple fiber non-woven geotextile.pdf

![]() 300g PET geotextiles test report.pdf

300g PET geotextiles test report.pdf

897.webp)

942.webp)

237.webp)