Enhancing Sand Cushions with Geosynthetics: A Structural Reinforcement Approach

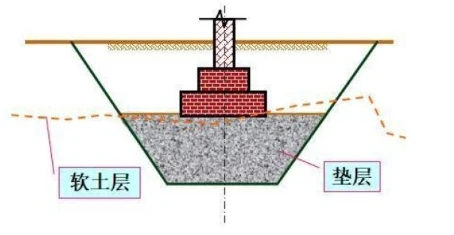

Sand cushions serve as crucial elements in various engineering applications, providing support and stability to infrastructure on soft or uneven ground. However, their effectiveness can be enhanced through the integration of geosynthetic materials. This article explores the utilization of geosynthetics to reinforce sand cushions, examining their suitability in different environments and their impact on bearing capacity.

Suitable Geosynthetic Materials

Geosynthetics offer a diverse range of materials suitable for reinforcing sand cushions across different environmental conditions. Geotextiles, geogrids, and geomembranes are commonly utilized. Geotextiles, for instance, are ideal for filtration and separation, while geogrids provide excellent reinforcement in soil structures. Geomembranes offer impermeable barriers, preventing water infiltration and enhancing stability.

Effect of Sand Cushion Thickness on Bearing Capacity

The thickness of the sand cushion plays a pivotal role in determining its bearing capacity. Thicker cushions distribute loads over a larger area, reducing the pressure exerted on the underlying soil. Consequently, thicker cushions generally exhibit higher bearing capacities, making them suitable for heavier loads and dynamic loading conditions.

Effect of Geosynthetic Tensile Strength on Bearing Capacity

The tensile strength of geosynthetic materials significantly influences the bearing capacity of reinforced sand cushions. Geosynthetics with higher tensile strengths provide superior reinforcement, effectively distributing loads and minimizing deformation. Consequently, selecting geosynthetics with appropriate tensile strengths is crucial in optimizing the bearing capacity of the sand cushion.

Relationship Between Bearing Capacity and Settlement

The relationship between bearing capacity and settlement of sand cushions of varying thicknesses is intricate. While thicker cushions typically exhibit higher bearing capacities, they may also experience greater settlement under loading. Understanding this relationship is essential for designing sand cushions that meet both load-bearing requirements and settlement criteria, ensuring long-term stability.

Effect of Thickness in Sand Cushion

The thickness of the sand cushion directly affects its load-bearing capacity. Thicker cushions offer increased resistance to settlement and deformation, particularly in soft or compressible soils. However, excessively thick cushions may be uneconomical and impractical, requiring a balance between thickness and structural performance.

Load-Bearing Capacity of Sand Pads with Different Structures

The load-bearing capacity of sand pads varies depending on their structural design and the integration of geosynthetics. Reinforced sand pads, incorporating geotextiles, geogrids, or geomembranes, exhibit enhanced stability and load-bearing capabilities compared to conventional pads. The specific load-bearing capacity of each structure depends on factors such as material properties, construction methods, and site conditions.

Summary and Conclusion

The integration of geosynthetics offers a versatile and effective solution for reinforcing sand cushions in various engineering applications. By selecting appropriate geosynthetic materials and optimizing cushion thickness and design, engineers can enhance bearing capacity, minimize settlement, and ensure long-term stability of infrastructure on soft or uneven ground. Understanding the complex interplay between geosynthetics, sand cushion thickness, and structural performance is essential for achieving optimal results in engineering projects.

About Haoyang

Haoyang Environmental Co., Ltd. (Haoyang) is a leading high-tech service provider specializing in geosynthetic materials. Established in June 2008, Haoyang offers comprehensive solutions for environmental engineering, including research, manufacturing, and consulting services. With a focus on using geosynthetics to reinforce sand cushions, Haoyang leverages its expertise in material development and environmental engineering to provide innovative solutions for infrastructure stability. The company holds certifications in quality management, environmental management, and occupational health and safety, ensuring the highest standards in its operations. Recognized as a key player in environmental protection, Haoyang boasts a dedicated R&D team and numerous patents, solidifying its position as a leader in the field.

If you have any needs please feel free to contact us.

897.webp)

942.webp)

237.webp)