What are composite geomembranes?

A composite geomembrane is a type of geomembrane composed of multiple layers of different materials. These layers are bonded together to create a single, durable, and impermeable barrier. Typically, composite geomembranes consist of a geomembrane layer (made of materials like high-density polyethylene or polyvinyl chloride) combined with other layers such as geotextiles or geonet materials.

Product properties

Composite geomembranes possess a range of product properties that make them highly effective in various engineering and environmental applications. Some key properties include:

1, Impermeability: Composite geomembranes are designed to provide excellent impermeability, preventing the passage of liquids and gases. This property is crucial for applications such as containment ponds, landfill liners, and wastewater treatment facilities.

2, Strength and Durability: These geomembranes are engineered to be strong and durable, with high tensile strength and tear resistance. This ensures long-term performance even in demanding environmental conditions, such as exposure to UV radiation, chemicals, and extreme temperatures.

3, Puncture Resistance: The composite structure of these geomembranes often includes layers that enhance puncture resistance, making them suitable for use in areas with sharp objects or rocky terrain.

4, Flexibility: Composite geomembranes exhibit flexibility, allowing them to conform to irregular surfaces and accommodate ground settlement without compromising their integrity. This property is essential for ensuring proper installation and long-term performance.

5, Compatibility: These geomembranes are compatible with various soil types, substrates, and construction materials, enabling seamless integration into different engineering projects.

6, UV Stability: Many composite geomembranes are formulated with additives to enhance UV stability, prolonging their service life when exposed to sunlight.

7, Chemical Resistance: They offer resistance to a wide range of chemicals, including acids, alkalis, and hydrocarbons, making them suitable for containment applications where chemical resistance is essential.

What are composite geomembranes uesed for?

Composite geomembrane, as a type of soil covering material that integrates leak prevention, soil stabilization, and environmental protection, has a wide range of applications and promising prospects. It can play a role not only in engineering fields such as road construction, environmental protection, and hydraulic engineering but also in agricultural production to improve crop yield and quality.

Firstly, composite geomembranes have a wide range of applications in road construction. In foundational engineering projects such as highways and urban roads, composite geomembranes can enhance soil durability, reduce foundation settlement, and improve the road's load-bearing capacity. Additionally, they can prevent water infiltration and soil erosion, effectively protecting the stability of road subgrades.

Secondly, composite geomembranes play a crucial role in environmental protection. In environmentally sensitive areas such as landfills and industrial pollution sites, composite geomembranes prevent waste or pollutants from leaking into the soil, safeguarding groundwater safety and overall environmental health. Moreover, they can be used in hydraulic engineering projects such as riverbank reinforcement and riverbed restoration, enhancing flood control, drainage, and other water resource management measures.

Thirdly, composite geomembranes also hold significant value in agricultural production. They can be utilized to cover channels, water troughs, and other parts of agricultural water conservancy projects, preventing water wastage and soil erosion, thus improving irrigation efficiency. Additionally, composite geomembranes can be applied in agricultural production processes such as vegetable greenhouses and field mulching, aiding in soil moisture control, weed suppression, and ultimately boosting crop yield and quality.

The differences between geomemrbane and composite geomembrane

The main differences between composite geomembranes and geomembranes lie in their composition and functional characteristics:

1, Product Form:

Geomembranes typically refer to single-ply thin films made of a single polymer material, such as high-density polyethylene (HDPE), polyvinyl chloride (PVC), or polypropylene (PP). They are used in impermeable, waterproof, anti-corrosion, isolation, and protection projects.

Composite geomembranes are a new type of composite material formed by combining geomembranes with other materials, which may include geotextiles, fibers, non-woven fabrics, etc. Composite geomembranes combine the characteristics of multiple materials, thus possessing superior comprehensive performance.

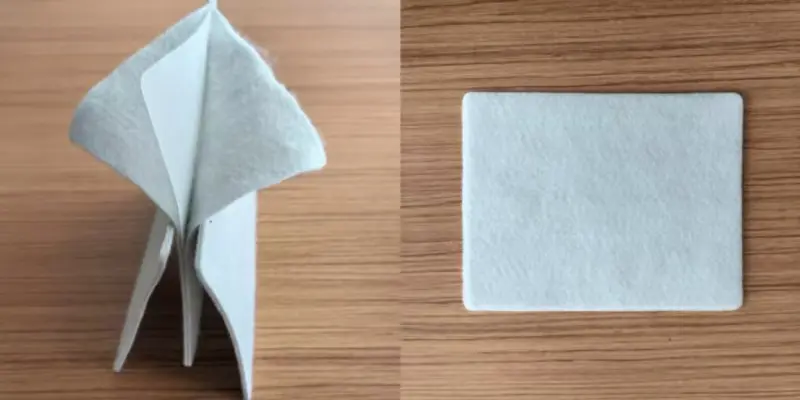

2, Product Appearance:

Geomembranes typically have a black appearance.

Composite geomembranes may appear white, depending on the base material and covering materials used.

3, Material and Manufacturing Process:

The production process of geomembranes may involve three-layer co-extrusion or flat rolling processes, using plastic resin granules as the main raw materials.

In the manufacturing process of composite geomembranes, in addition to the geomembrane itself, other materials such as polyester fiber non-woven fabric may be included, thereby enhancing the functionality and durability of the product.

4, Functionality:

Geomembranes primarily provide functions such as impermeability, waterproofing, anti-corrosion, isolation, and protection. They are corrosion-resistant, aging-resistant, tear-resistant, and have good impermeability, suitable for various geological environments and engineering applications.

Composite geomembranes, while possessing all the basic functions of geomembranes, also enhance durability, tensile strength, and resistance to ultraviolet (UV) and low-temperature environments

897.webp)

942.webp)

237.webp)