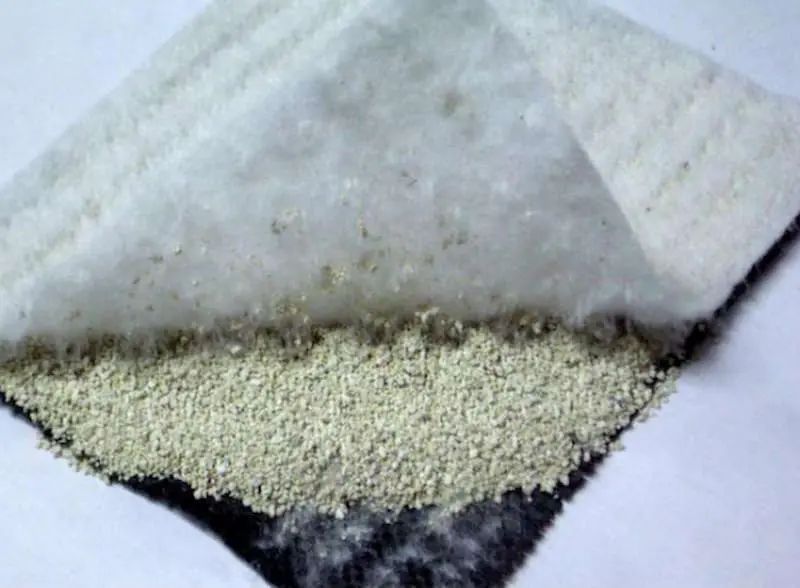

Geosynthetic Clay Liner (GCL), also know bentonite waterproof blanket, is composite materials used primarily in environmental and civil engineering applications. These materials consist of a layer of high-swelling sodium bentonite sandwiched between two geotextiles.

GCL mainly uses the principle of bentonite swelling in contact with water. The bentonite selected in the waterproof blanket can expand at least tens of times after being dissolved in water. The geotextiles help to contain the bentonite and provide structural support, ensuring that the material remains in place even under pressure. By locking the bentonite layer between two layers of geotextiles by needling, a uniform dense colloidal structure with high viscosity and small hydraulic permeability coefficient can be formed, which can play a good role of anti-seepage.

The primary function of Geosynthetic Clay Liners GCLs is to provide an effective barrier against the penetration of liquids, such as water or leachate, which is beneficial to the realization of anti-seepage effect of the project.

Classification of Geosynthetic Clay Liner (GCL)?

•Sodium bentonite waterproof blanket and Calcium bentonite waterproof blanket: According to raw materials, GCL is divided into sodium bentonite waterproof blanket and calcium bentonite waterproof blanket. The expansion coefficient of sodium bentonite is higher than that of calcium bentonite.

•GCL-NP, GCL-OF, GCL-AH: According to the structure, GCL can be divided into three types: Needled sodium bentonite waterproof blanket (GCL-NP), Needle-coated sodium bentonite waterproof blanket (GCL-OF), Adhesive process sodium bentonite waterproof blanket (GCL-AH).

281625.webp)

The main products of Haoyang is GCL-NP, which has a high expansion coefficient to ensure that the bentonite expands in contact with water to form a more dense colloidal structure and has a lower permeability coefficient, which is conducive to the realization of the anti-seepage effect of the project.

Advantages of Geosynthetic Clay Liner GCL

1. Good anti-seepage function:

Sodium bentonite has a high swell capacity, meaning it can absorb a large amount of water and expand significantly. This swelling action creates a dense, low-permeability barrier that effectively prevents the passage of water and other liquids.

2. Low Permeability:

The expanded bentonite forms a highly impermeable layer. This characteristic makes bentonite an excellent material for preventing the migration of contaminants and protecting the environment from pollution.

3. Good self-healing function:

When bentonite comes into contact with water, it swells and fills any small cracks or voids, creating a self-sealing effect. This self-sealing property ensures that the barrier remains intact and effective even if minor damage occurs, reducing the risk of leaks.

4. Cost-Effectiveness:

Compared to traditional clay liners, bentonite waterproofing materials GCL are generally more cost-effective. They require less material and are easier to transport and install, leading to lower overall project costs.

5. Ease of Installation:

Bentonite waterproofing materials GCLs, are lightweight and easy to handle. This ease of installation reduces labor costs and speeds up the construction process, making it ideal for large-scale projects.

6. Environmental Sustainability:

Bentonite is a natural, non-toxic, and environmentally friendly material. Its use in waterproofing and containment applications helps to protect the environment by preventing the spread of contaminants and ensuring the long-term sustainability of engineering projects.

7. Adaptability to Various Conditions:

Bentonite can adapt to a wide range of environmental conditions, including variations in temperature and moisture. This adaptability makes it suitable for use in diverse climates and site conditions, ensuring reliable performance in different environments.

Applications of Geosynthetic Clay Liner GCL:

•Landfills: GCLs are widely used in landfill construction to line the base and sides, providing a secondary containment system that prevents the migration of leachate into the groundwater.

•Pond Linings: They are used in the lining of ponds, including industrial wastewater lagoons, to prevent seepage and protect the underlying soil and water resources.

•Canal and Reservoir Linings: In irrigation and water storage projects, GCLs can be used to line canals and reservoirs, reducing water loss through seepage.

•Mining and Industrial Sites: GCLs are employed in the containment of hazardous waste and tailings, ensuring that these materials do not contaminate the surrounding environment.

Quality Control of Geosynthetic Clay Liner GCL in Haoyang Company:

As a large geomaterial production enterprise in China, adhering to product quality innovation and integrity management is Haoyang’s basic concept.

Quality control of GCL products in Haoyang is mainly from the following 4 aspects to ensure and control the quality of finished products.

1. Quality control of raw and auxiliary materials:

The quality control of raw and auxiliary materials is the premise of finished product quality control. To ensure the quality of finished products, we must first ensure the quality of raw and auxiliary materials, including the Internal control standards of raw material manufacturers, sampled incoming tests and sample retained after testing.

2. Quality control of production process:

The quality control of the production process is the key to the quality control of the finished product. To ensure the quality of the finished product, the quality control of the production process must be strengthened. Haoyang focus on the quality control of production order issuing process, recording of process parameters during production, inspection and spot check of finished products and measurement of mass per unit area of GCL.

3. Quality control of finished products:

The quality inspection of finished Geosynthetic Clay Liners GCLs include Bentonite properties testing (Expansion index and Blue absorption capacity) and Waterproof blanket performance testing (Mass per unit area, Tensile strength, Peel strength,. ect.)

Testing standards in below table are the standards used by Haoyang:

JG/T 193-2006 | Geosynthetic Clay Liner GCL |

CJJ 113-2007 | Technical specification for seepage control system engineering of sanitary landfill for domestic waste |

JG/T 193-2006 | Standard Specification for “Test Methods, Required Properties, and Testing Frequencies of Geosynthetic Clay Liners (GCLs)” |

ASTM D5889-11 | Standard Practice for Quality Control of Geosynthetic Clay Liners |

ASTM D6495-09 | Standard Guide for Acceptance Testing Requirements for Geosynthetic Clay Liners |

4. Traceability

Traceability plays an important role in the process of the product quality control.

If there is a quality problem of the sold product, it can be traced from the product information to the testing information of the finished product, the sample information of the finished product, the production process information of the finished product, the raw material information of the finished product, etc., so as to find the root cause of the quality problem and provide an important basis for the guarantee and improvement of product quality.

Installation Considerations of Geosynthetic Clay Liner GCL:

•Site Preparation: Proper site preparation is essential to ensure a smooth and stable surface for the GCL. Any sharp objects or irregularities should be removed to prevent punctures.

•Hydration Control: Care must be taken to control the hydration of the bentonite during installation. Excessive hydration can lead to the displacement of the bentonite, while insufficient hydration may result in poor performance.

•Seaming and Overlap: Seams and overlaps in the GCL should be carefully managed to ensure a continuous and impermeable barrier. Typically, seams are overlapped and secured using a specialized adhesive or stitching.

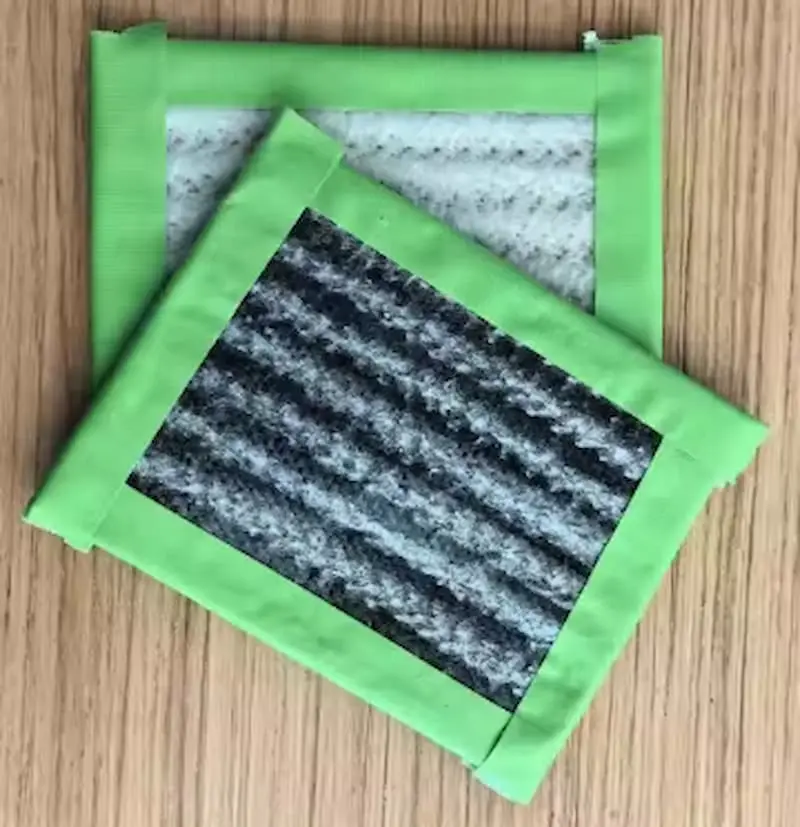

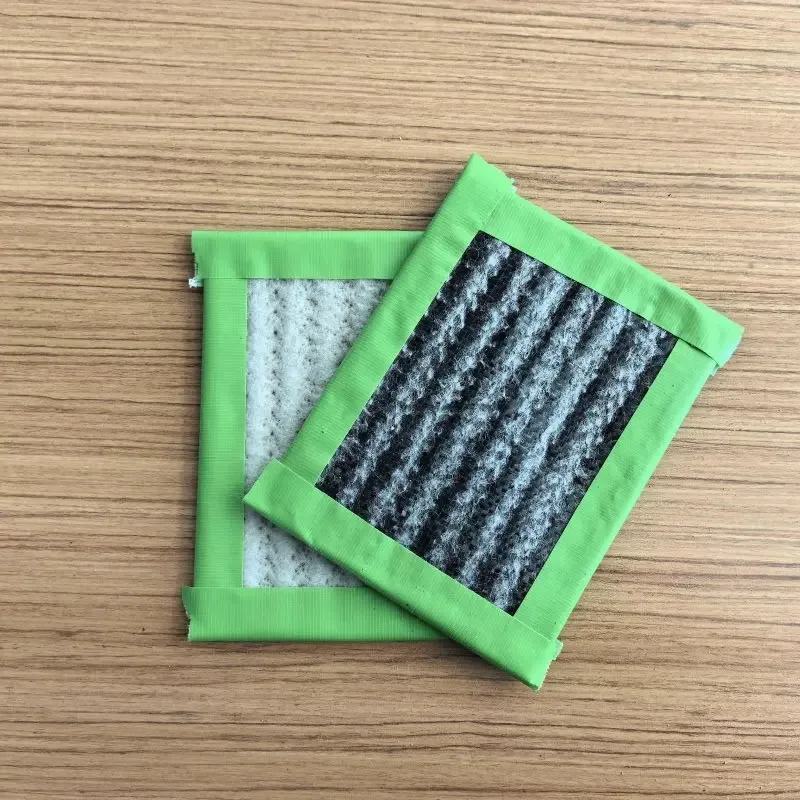

Special design of Haoyang’s Geosynthetic Clay Liner GCL for installation

In the construction process, the lap joint between different rolls of Geosynthetic Clay Liner GCLs is realized by overlapping two rolls with a certain width, and sprinkling bentonite particles on the overlapping place, without other fixing measures at the edge. The GCLs with a roll length of tens of meters is prone to deviation in the process of edge lap laying, and the problems of insufficient lap width of two rolls or soil spreading width exist the risk of forming anti-seepage. The Geosynthetic Clay Liners GCLs produced by Haoyang company has an obvious lap width mark at the standard width of the product, which is convenient for standardized construction and greatly reduces the risk of anti-seepage.

The improvement of the compaction degree of the waterproof blanket GCL is conducive to its lifting or shoveling in the construction process. In order to increase the compaction degree of the waterproof blanket, our company added a thick bamboo rod as the core of the coiled bentonite waterproof blanket (GCL). The waterproof blanket Geosynthetic Clay Liner GCL has a good compaction degree and is convenient for construction operation.

Conclusion

Geosynthetic Clay Liner (GCLs) are versatile and effective solutions for a wide range of containment and waterproofing applications. Their unique properties, ease of use, and environmental benefits make them a preferred choice in many engineering projects. The use of high quality Geosynthetic Clay Liner (GCL) is more conducive to ensuring the engineering effect and improving the construction efficiency.

897.webp)

942.webp)

237.webp)