High-density polyethylene pipe comes in different lengths. HDPE pipe for water supply and other high-pressure applications is usually available in straight lengths between 20 and 100 feet.

If longer pipe is needed, or the pipe needs to make a bend, HDPE pipe joining methods can be used.

What are the most common ways to join HDPE pipe? Learn about the five joining techniques contractors use to join HDPE pipe.

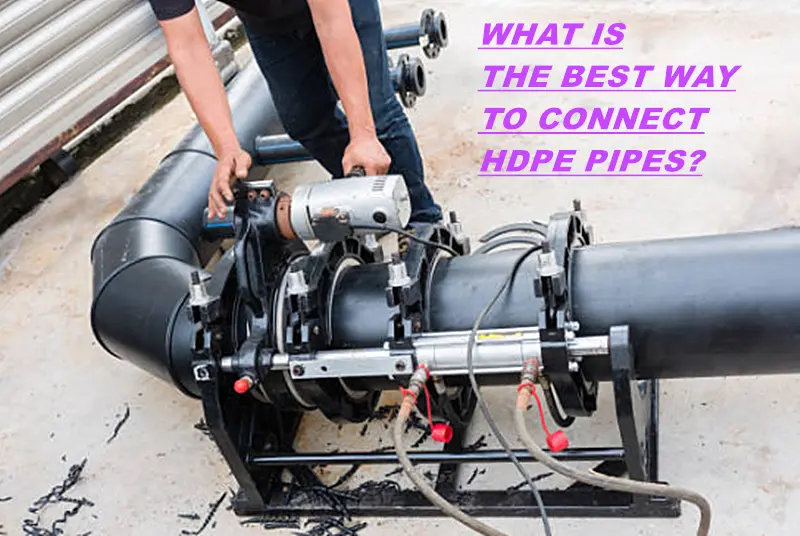

1. The best way to connect HDPE (high-density polyethylene) pipes depends on the specific application environment and requirements, but the following methods are commonly used and effective:

1.1. Butt-melt welding

Principle: Use a heating tool to heat the two ends of the pipe to a molten state, then quickly butt them together, cool and solidify them to form a firm connection.

Advantages:

High strength: The strength of the connection is equivalent to the pipe itself. Suitable for large-diameter pipes. High long-term reliability.

Application: Suitable for pressure pipes and transportation systems, such as water and gas pipes.

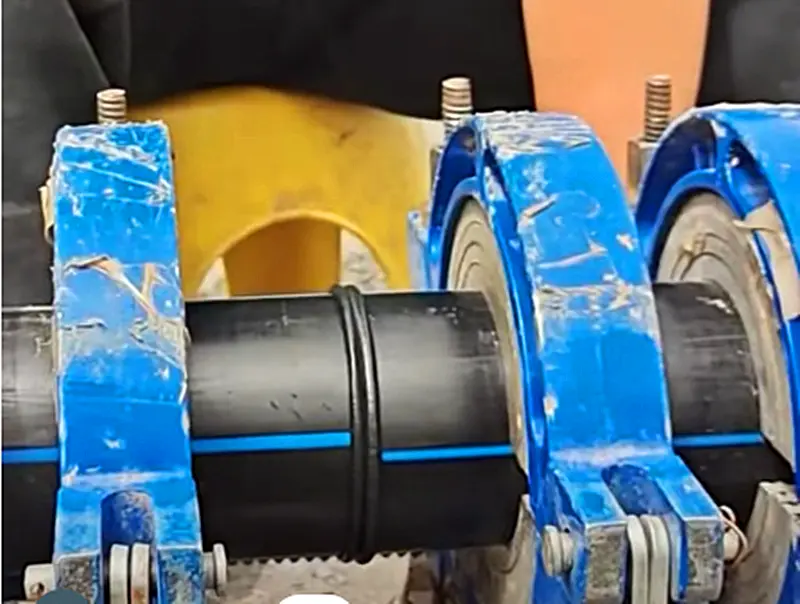

1.2. Electric fusion connection

Principle: Use an electric fusion sleeve with a resistance wire at the pipe connection, and heat it with electricity to melt the sleeve and the pipe together.

Advantages:

The operation is relatively simple. Suitable for pipe connections of different diameters and complex shapes. The connection quality is controllable.

Application:

Commonly used for maintenance and complex pipe system connections.

1.3. Flange connection

Principle: Install flanges at both ends of the pipe, connect the flanges together with bolts, and add sealing gaskets in the middle to prevent leakage.

Advantages:

Easy to disassemble and repair. Suitable for pipe systems that need to be disassembled frequently.

Applications:

Commonly used for connecting pumps, valves and other equipment to pipes.

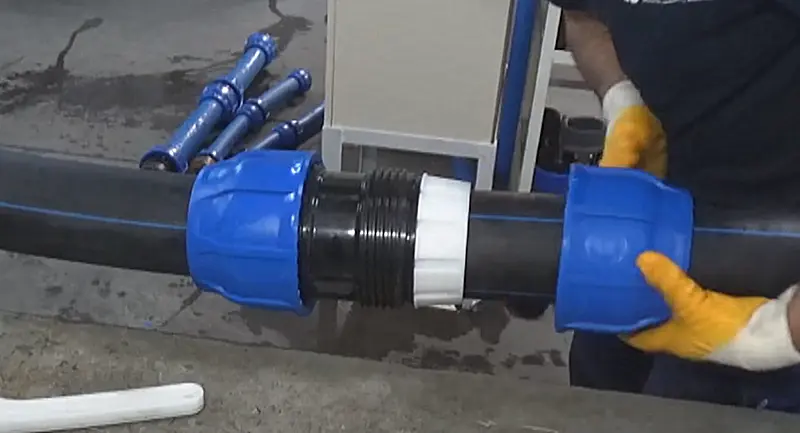

1.4. Socket connection

Principle: Insert the end of the pipe into the socket through a special socket, and use a sealing ring or sealant to ensure the sealing of the connection.

Advantages:

Simple construction. Suitable for small-diameter pipes.

Applications:

Commonly used in low-pressure systems such as drainage and irrigation.

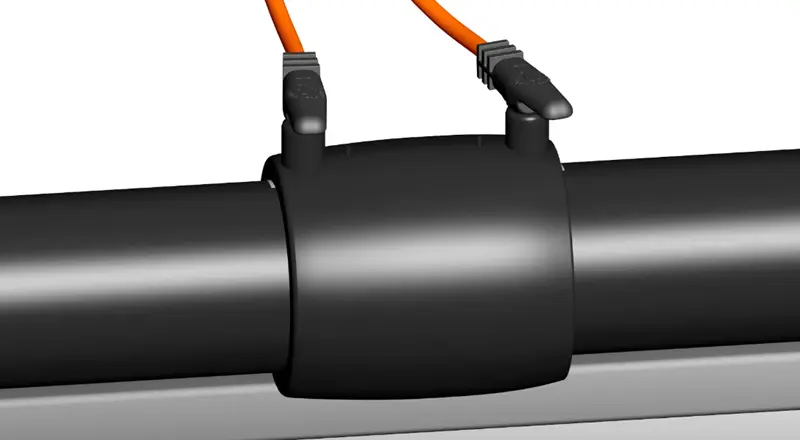

1.5. Mechanical connection

Principle: Use mechanical clamps or clamps to connect pipes together, usually with sealing rings to ensure sealing.

Advantages:

Quick and convenient installation. No special tools or equipment are required.

Applications:

Temporary pipe connection or emergency repair.

2. Considerations for choosing the best connection method

2.1Pipeline diameter: Large-diameter pipes are usually connected by hot-melt butt welding or flange connection.

2.2Application scenarios: Pressure pipe systems are mostly connected by hot-melt butt welding or electric fusion; temporary pipes or systems that need to be disassembled frequently are mostly connected by flange connection or mechanical connection.

2.3Operating conditions: The construction environment, site conditions and the technical level of the operator will affect the choice of connection method.

2.4Cost: The cost of each connection method is different. When choosing, you need to consider equipment investment, construction cost and maintenance cost.

3. Conclusion

Butt fusion welding and electric fusion connection are the most commonly used and reliable HDPE pipe connection methods, especially suitable for high-strength pipe systems that are used for a long time. For systems that require convenient disassembly and maintenance, flange connection and mechanical connection are good choices. The specific choice should be based on the purpose of the pipeline system, construction conditions and economic costs.

Our company specializes in manufacturing high-quality HDPE pipes that are designed for durability and reliability. We cater to various industrial and commercial applications, including water supply, drainage systems, and irrigation. With our commitment to excellence and customer satisfaction, we are always ready to assist you with your HDPE pipe needs. Please feel free to contact us for more information.

897.webp)

942.webp)

237.webp)