1. Introduction

Geocomposite drainage mats are advanced drainage solutions that integrate multiple geosynthetic layers—typically a drainage core bonded with geotextile fabric—to perform key functions such as water conveyance, filtration, and structural protection. Unlike single-function traditional materials such as gravel or basic drainage boards, geotextile composites offer multifunctionality in one engineered product.

Why choose geocomposite drainage mats over traditional options? Traditional drainage methods often involve the use of heavy gravel layers or single-layer plastic drainage boards. These materials are bulky, labor-intensive to install, and may lack consistent performance over time. Geocomposite drainage mats, by contrast, provide a lightweight, cost-effective, and high-performance alternative that excels in various engineering applications.

This article explores the key advantages of geocomposite drainage mats, their typical application areas, selection criteria, installation tips, and common questions, helping you make informed decisions for your drainage needs.

2. Key Benefits of Geocomposite Drainage Mats

Efficient Drainage Performance

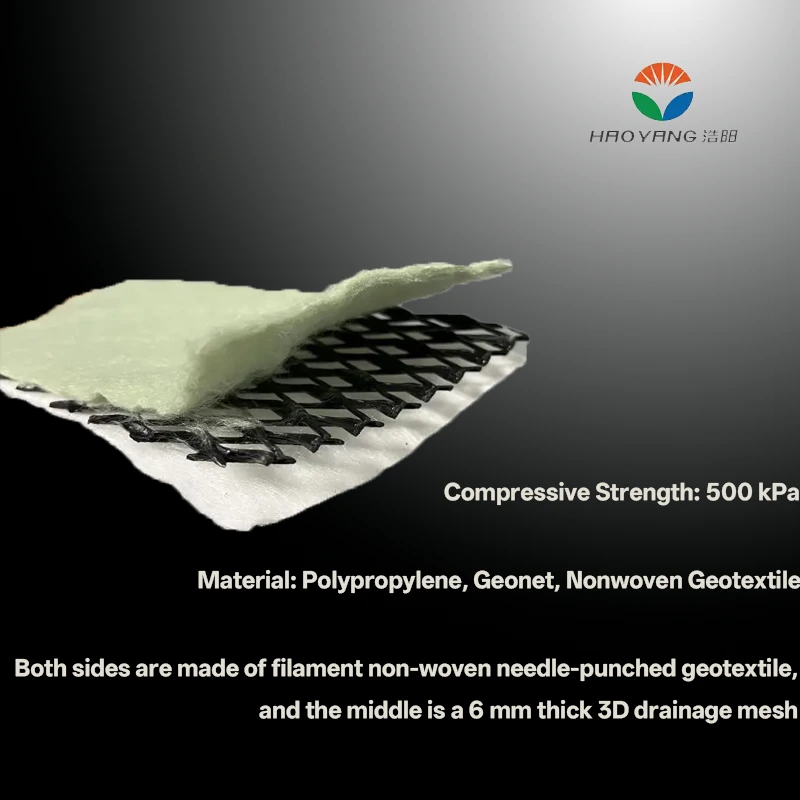

The unique multilayer structure of geocomposite drainage mats, typically combining a cuspated HDPE core with a nonwoven geotextile layer, facilitates rapid lateral water movement while filtering out soil particles.

Permeability: Laboratory tests such as ASTM D4716 show in-plane flow rates reaching 12-50 L/(m·min) under 100 kPa load, outperforming compacted gravel layers.

Anti-clogging design: The geotextile layer ensures filtration efficiency and long-term performance by preventing fine soil particles from blocking the drainage core.

Lightweight and Cost-Saving

Compared to gravel layers which require large volumes of mined material and heavy machinery for installation, geotextile composites are pre-manufactured, lightweight rolls that significantly reduce:

Transportation costs

Installation time

Labor requirements

| Feature | Geocomposite Mat | Traditional Gravel Layer |

|---|---|---|

| Weight | ~1.2-2.5 kg/m² | ~1500-2000 kg/m³ |

| Installation Time | Fast (1-2 laborers) | Slow (heavy equipment needed) |

| Transportation Cost | Low | High |

| Material Usage | Optimized and efficient | High, with wastage |

Compression Resistance and Durability

Geocomposite drainage mats are engineered to withstand high compressive forces.

Compressive Strength: Models often exceed 500 kPa, making them suitable for high-load applications such as roadbeds, tunnel linings, and basement walls.

Chemical & Root Resistance: Resistant to acid, alkali, microbial attack, and root penetration—ideal for green roofs, vegetative walls, and waste containment.

Environmental Protection and Sustainability

Reduces reliance on mined materials like gravel and sand, minimizing ecological disruption.

Recyclable materials such as HDPE and polypropylene contribute to greener project designs.

Lower carbon footprint due to reduced transportation and excavation.

Multifunctional Integration

A geotextile composite drainage mat offers several integrated benefits:

Drainage: Facilitates fast water removal.

Filtration: Blocks fine particles while allowing water flow.

Protection: Acts as a cushion for waterproofing membranes.

Separation: Maintains layer integrity in road subgrades and construction fill.

3. Typical Applications

Civil Engineering and Infrastructure

Road and railway subgrades: Prevents water accumulation, reducing the risk of frost heave and soil softening.

Tunnel and retaining wall drainage: Keeps structures dry and stable by managing seepage and hydrostatic pressure.

Building Waterproofing Projects

Basement waterproofing: Installed adjacent to foundation walls to divert water away and protect waterproofing membranes.

Roof garden drainage: Maintains healthy vegetation by controlling water accumulation and preventing root damage.

Landscape and Agriculture

Sports fields and golf courses: Ensures rapid surface water removal to keep fields playable.

Agricultural fields: Manages excess moisture and improves crop resilience to heavy rain.

Environmental Protection Projects

Landfill leachate collection: Directs harmful liquids away from the waste mass to collection systems.

Artificial wetlands: Controls water levels and supports filtration in ecological restoration.

4. How to Select the Right Geocomposite Drainage Mat

Key Parameters to Consider:

Permeability rate: Confirmed via ASTM D4716 or ISO 12958.

Compressive strength: For heavy-duty applications, look for models rated at CC5 or higher.

Thickness: Typically ranges from 3.5 mm to 8.5 mm depending on load and flow requirements.

Material type: Choose HDPE for chemical resistance and durability; PP for flexibility.

Match to Project Requirements:

Roads and tunnels: Need high compressive strength and thick drainage cores.

Green roofs and basements: Require root-resistant, chemically stable models.

Brand and Certification

Look for products certified under ISO 9001, ISO 14001, and GRI-GM13 standards.

Reputable manufacturers provide third-party lab testing and traceability.

5. Installation Tips

Site preparation: Clear and level the substrate; remove sharp objects that may damage the mat.

Laying direction: Follow slope direction to facilitate drainage.

Overlap: Minimum 10 cm side overlap. Use heat-welding or adhesive for seam bonding where necessary.

Protective layer: Cover with a geotextile or sand layer to prevent clogging and mechanical damage during backfilling.

6. Frequently Asked Questions (FAQs)

Q: What is the typical service life of a geocomposite drainage mat?

A: Over 50 years under normal conditions, depending on material quality and UV exposure.

Q: Can geocomposite mats be used for vertical applications?

A: Yes, but select models with self-adhesive backing or mechanical anchoring features.

Q: Are they more expensive than regular drainage boards?

A: Initial costs are higher, but lower installation and maintenance expenses provide cost advantages over time.

7. Conclusion

Geocomposite drainage mats represent a modern, effective, and sustainable drainage solution for diverse engineering needs. By offering superior efficiency, cost savings, and environmental benefits compared to traditional materials, they are fast becoming the go-to choice for engineers and builders alike.

For high-performance, certified, and customizable geotextile composite drainage mats, consult trusted manufacturers like Haoyang Environmental Co., Ltd. and ensure the long-term success of your project.

Haoyang Environmental Co., Ltd.: Pioneering Geosynthetic Solutions

Established in June 2008, Haoyang Environmental Co., Ltd. (Haoyang) stands as a high-tech comprehensive service provider specializing in geosynthetic material research and development, manufacturing, and environmental engineering consulting. With certifications including ISO 9001, ISO 14001, and OHSAS 18001, Haoyang is committed to delivering quality and sustainable solutions.

The company's expertise encompasses environmental engineering design, soil remediation, and comprehensive solid waste treatment. Haoyang's dedication to innovation is evident in its portfolio of three invention patents and 32 utility model patents. Recognized as the "Shandong Enterprise Technology Center" and the "Environmental Protection New Materials Engineering Laboratory," Haoyang continues to lead in the development and application of advanced geosynthetic materials.

897.webp)

942.webp)

237.webp)