High-Density Polyethylene (HDPE) geomembranes have become the preferred lining material for various applications due to their durability, resistance to environmental conditions, and cost-effectiveness. One of the most popular uses of HDPE geomembranes is in the construction of fish ponds, where a high-quality liner is essential to maintain water integrity, prevent leaks, and create a controlled aquatic environment. In this article, we will explore the key considerations for selecting HDPE geomembranes for fish ponds, including the material properties, thickness and size selection, and important factors regarding installation and construction methods.

Specifications Table for HDPE Geomembrane for Fish Ponds

| Specification | Description |

|---|---|

| Material | High-Density Polyethylene (HDPE) |

| Thickness | 0.5mm, 0.75mm, 1.0mm, 1.5mm, 2.0mm |

| Width | 2m - 8m (custom widths available) |

| Length per Roll | 50m - 200m (varies by thickness) |

| Density | 0.94 g/cm³ |

| Tensile Strength | ≥ 25 MPa (varies with thickness) |

| Elongation at Break | ≥ 700% |

| Tear Resistance | ≥ 110 N/mm |

| Puncture Resistance | ≥ 300 N/mm |

| Waterproofing | 100% waterproof, suitable for water retention in fish ponds |

| UV Resistance | UV-stabilized for outdoor exposure |

| Temperature Range | -40°C to 60°C (-40°F to 140°F) |

| Environmental Compliance | Meets ISO and ASTM standards for environmental safety |

| Color Options | Black (standard), white, blue (custom colors available) |

| Lifespan | 20-30 years in proper conditions |

1. Material Selection: Why HDPE?

HDPE geomembrane is a highly popular material for fish ponds due to its superior chemical resistance, long-term performance, and environmentally friendly properties. The primary reasons why HDPE is preferred over other materials are:

Durability: HDPE offers high resistance to UV radiation, chemicals, and environmental stress, making it ideal for outdoor applications like fish ponds.

Flexibility and Strength: HDPE geomembranes are flexible enough to conform to uneven surfaces but rigid enough to resist punctures and mechanical damage.

Waterproofing Capability: The material’s impermeability makes it perfect for retaining water in fish ponds, ensuring minimal seepage and reducing water loss.

Environmental Safety: HDPE geomembranes are non-toxic and safe for aquatic life, an essential consideration for fish ponds, where the health of fish and other organisms is paramount.

HDPE geomembranes are also recyclable and can be produced from virgin raw materials, ensuring they meet stringent quality standards for environmental applications.

2. Thickness Selection

The thickness of the HDPE geomembrane liner is one of the most critical factors influencing the performance and longevity of fish ponds. The thickness of the liner should be selected based on the pond size, depth, and intended use.

Common Thicknesses: HDPE geomembrane liners typically range from 0.5 mm to 2.5 mm in thickness. For fish pond applications, the most commonly used thicknesses are between 0.75 mm and 1.5 mm.

Thin Liners (0.5 mm - 0.75 mm): These thinner liners are suitable for small fish ponds that are relatively shallow and where the risk of mechanical damage is low. While they are cost-effective, they offer less puncture resistance.

Medium Liners (1.0 mm - 1.5 mm): For larger and deeper fish ponds, a medium thickness is usually recommended. This range strikes a balance between flexibility, durability, and cost.

Thick Liners (2.0 mm and above): In large, commercial, or industrial fish farms, thicker geomembranes are used to provide maximum puncture resistance and to handle more significant mechanical stresses. These thicker liners are especially recommended if the pond is subject to rough usage, such as frequent maintenance work or if it's situated on rocky terrain.

Choosing the right thickness is essential for ensuring the long-term effectiveness of the liner. A thicker liner generally means more durability but comes at a higher cost. Thus, the final decision should be based on the pond’s specific requirements and budget considerations.

3. Size Selection and Customization

The size of the geomembrane liner is another important consideration. HDPE geomembranes are typically available in large rolls, and the liner needs to be sized appropriately for the fish pond to ensure proper coverage without excessive seams.

Standard Roll Sizes: HDPE geomembrane rolls typically come in widths ranging from 5 meters to 8 meters, with lengths ranging from 50 meters to 100 meters, depending on the manufacturer. Wider rolls help reduce the number of seams required, improving the integrity of the installation.

Custom Sizing: Many manufacturers offer custom sizes to fit specific pond dimensions. When calculating the liner size, consider not only the pond’s surface area but also the depth and allowance for anchoring on the sides of the pond. The liner should extend beyond the pond’s perimeter to prevent slippage.

Seam Considerations: Fewer seams mean fewer potential weak points in the liner. If the pond is large and requires multiple liner sheets to cover the entire area, ensure that the seams are welded correctly using high-quality seam sealing methods.

4. Installation Conditions

Several factors influence the successful installation of an HDPE geomembrane for fish ponds. The environmental and site conditions during installation can have a significant impact on the liner’s performance and longevity.

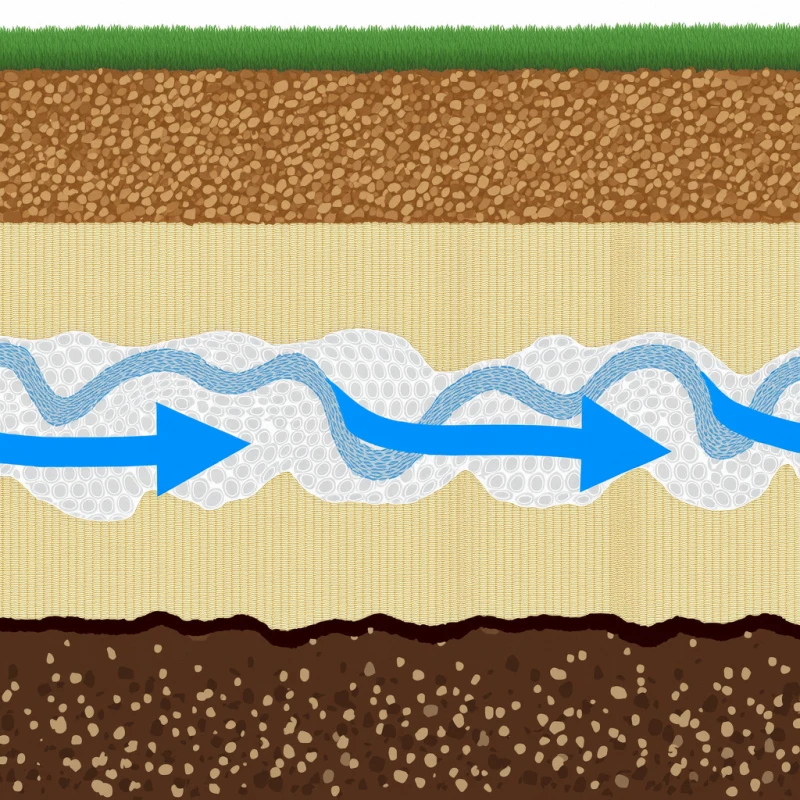

Subgrade Preparation: The pond’s subgrade must be smooth and free of sharp objects, rocks, roots, or debris that could puncture or damage the liner. A well-prepared subgrade provides a solid foundation for the geomembrane, reducing the risk of punctures.

Weather Conditions: HDPE geomembranes should ideally be installed in moderate weather conditions. Extreme temperatures—both hot and cold—can affect the flexibility and workability of the liner. Installation should be avoided during high winds, heavy rainfall, or freezing conditions, as these can hinder proper liner placement and seam sealing.

UV Exposure: Although HDPE geomembranes are resistant to UV radiation, prolonged exposure during installation can lead to unnecessary degradation. It is advisable to minimize the time between unpacking the liner and securing it in place to reduce UV exposure.

5. Installation Methods

The installation of an HDPE geomembrane requires a systematic approach to ensure that the liner is securely placed and performs as expected. The following steps outline the standard installation procedure:

Unrolling the Liner: The HDPE liner should be unrolled carefully across the pond area. Large liners can be heavy and may require specialized equipment for handling. It’s important to align the liner properly, making sure there is enough overlap at the edges for seam welding.

Seam Welding: Seams must be welded together to ensure a watertight seal. HDPE geomembranes are typically welded using thermal fusion techniques, such as hot wedge welding or extrusion welding. These methods melt the edges of the liner and fuse them together, creating a strong, impermeable seam.

Testing Seams: After welding, the seams should be tested for integrity. Non-destructive testing methods, such as air pressure testing or vacuum testing, are used to detect leaks or weak points in the seam.

Anchoring the Liner: Once the liner is in place, it should be anchored securely along the edges of the pond. This is often done by burying the liner in a trench around the perimeter of the pond. Proper anchoring prevents the liner from shifting or floating when the pond is filled with water.

Filling the Pond: After installation, the pond can be filled with water. It is recommended to fill the pond gradually while checking for any signs of stress or damage to the liner.

Conclusion

HDPE geomembranes are an ideal choice for lining fish ponds due to their durability, flexibility, and impermeability. Selecting the right material, thickness, and size ensures long-lasting performance and reduces the risk of damage or leaks. Proper installation techniques and environmental considerations are equally important in maximizing the lifespan of the liner. By following these guidelines, fish pond owners can create a sustainable, leak-free pond that ensures a healthy environment for aquatic life.

No. | Item | Unit | Index | ||||||||

1 | Thickness | mm | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

2 | Density | g/cm3 | ≧0.940 | ||||||||

3 | Tensile yield strength | N/mm | ≧4 | ≧7 | ≧10 | ≧13 | ≧16 | ≧20 | ≧26 | ≧33 | ≧40 |

4 | Tensile breaking strength | N/mm | ≧6 | ≧10 | ≧15 | ≧20 | ≧25 | ≧30 | ≧40 | ≧50 | ≧60 |

5 | Yield elongation | % | - | - | - | ≧11 | |||||

6 | Break Elongation | % | ≧600 | ||||||||

7 | Right-angle Tearing strength | N | ≧34 | ≧56 | ≧84 | ≧115 | ≧140 | ≧170 | ≧225 | ≧280 | ≧340 |

8 | Puncture strength | N | ≧72 | ≧120 | ≧180 | ≧240 | ≧300 | ≧360 | ≧480 | ≧600 | ≧720 |

9 | Carbon black content | % | 2.0~3.0 | ||||||||

10 | Dispersion of carbon black | - | There is not more than one level 3 in 10 data, and level 4 and level 5 are not allowed to exist. | ||||||||

11 | Oxidation induction time | min | ≧60 | ||||||||

12 | Low temperature impact embrittlement properties | - | Pass | ||||||||

13 | Water vapor permeability coefficient | g.cm/ (cm2.s.Pa) | ≦1.0*10-13 | ||||||||

14 | Dimensional stability | % | ±2.0

| ||||||||

Note | Technical performance indicators for thickness specifications not listed in the table are required to be performed by interpolation. | ||||||||||

Price List for HDPE Geomembrane for Fish Ponds

| Thickness | Roll Size | Factory Price (USD per Square Meter) | Factory Price (USD per Roll) | Application |

|---|---|---|---|---|

| 0.5mm | 100m x 6m | $0.80 - $1.10 | $480 - $660 | Small fish ponds, lightweight applications |

| 0.75mm | 100m x 6m | $1.00 - $1.30 | $600 - $780 | Medium-sized fish ponds, water features |

| 1.0mm | 100m x 6m | $1.20 - $1.60 | $720 - $960 | Larger ponds, increased durability |

| 1.5mm | 100m x 6m | $1.80 - $2.20 | $1,080 - $1,320 | Heavy-duty fish ponds, aquaculture farms |

| 2.0mm | 100m x 6m | $2.40 - $3.00 | $1,440 - $1,800 | Industrial fish farms, long-term use |

Note: Prices may vary based on order quantity, location, and specific customization requirements. Discounts are available for bulk purchases.

HDPE geomembranes are an excellent choice for fish ponds due to their high durability, flexibility, and waterproof nature. Available in various thicknesses, they provide a reliable solution for water retention, ensuring a safe and stable environment for aquaculture. With UV resistance and a long lifespan, these geomembranes can withstand outdoor conditions, making them ideal for use in fish ponds, lakes, and water reservoirs.

At Haoyang, we pride ourselves on providing superior-grade HDPE geomembranes tailored for fish ponds. Our products ensure durability, flexibility, and exceptional resistance to chemicals and water seepage, creating a safe and healthy environment for aquatic life. The high-density polyethylene material guarantees long-lasting performance, making it the ideal choice for your fish farming needs. Welcome to place your order and experience the peace of mind that comes with Haoyang's quality geomembranes.

223.webp)

282.webp)

136.webp)

247.webp)

674.webp)

311.webp)

889.webp)