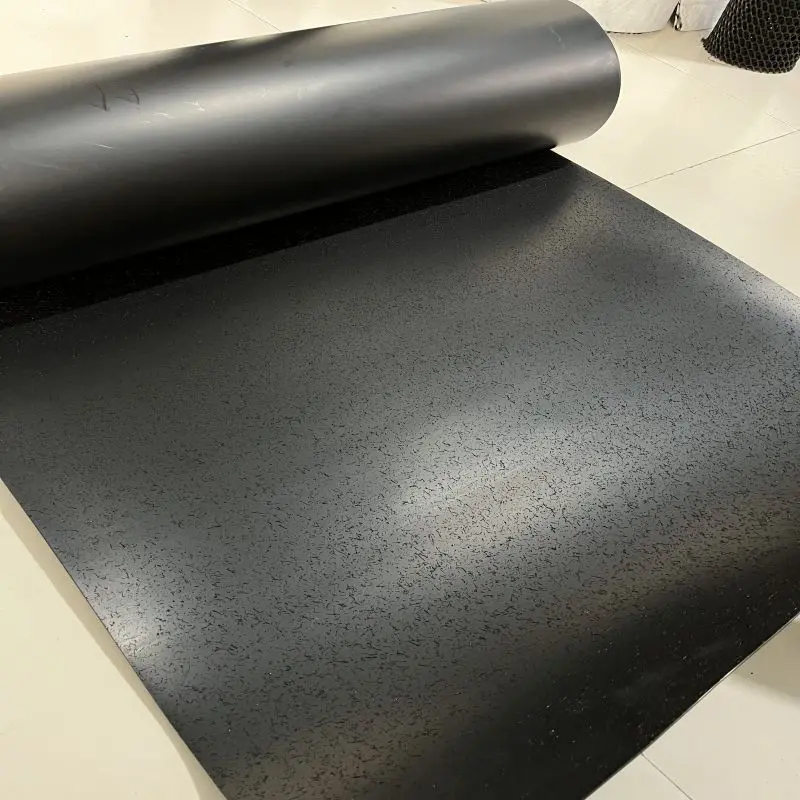

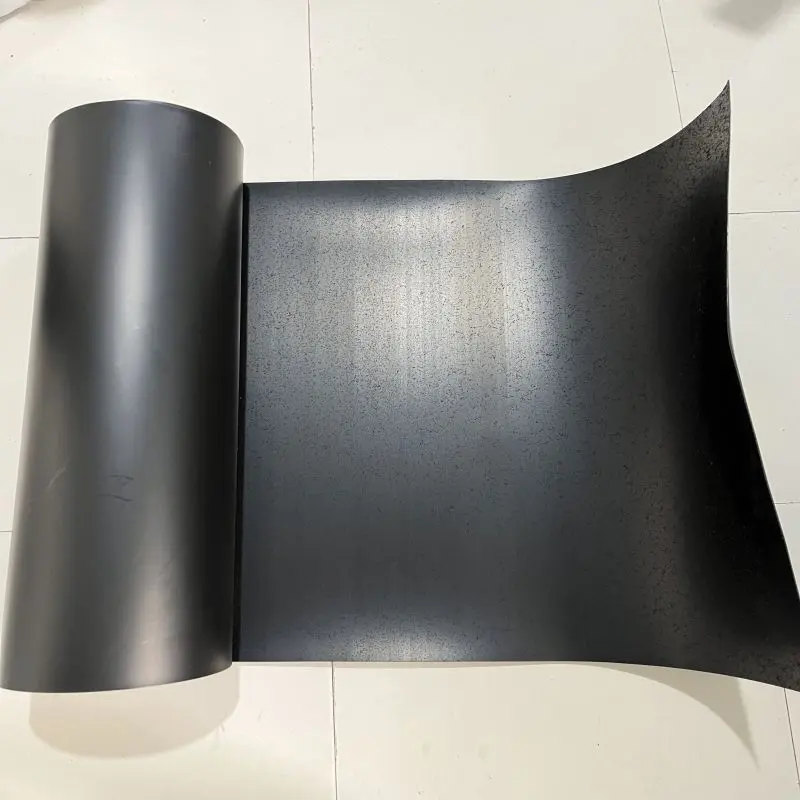

1.5mm Single-Textured Geomembrane

At Haoyang Environmental Co., Ltd., we are proud to present our advanced 1.5mm single-textured geomembrane, a cutting-edge solution in the field of geosynthetics. Designed for robust performance in the most demanding environmental conditions, our geomembrane is engineered to provide superior protection and reliability for various applications, including soil stabilization, seepage prevention, and chemical erosion resistance.

A single-textured geomembrane is a geosynthetic material usually made from high-density polyethylene (HDPE), featuring a surface with a certain level of roughness. This unique design allows it to excel in addressing soil movement, preventing seepage, and resisting chemical erosion. Single-textured geomembranes exhibit advantages such as corrosion resistance, aging resistance, and high mechanical strength, making them suitable for various extreme environmental conditions,such as red mud reservoir comprehensive utilization project.

Specification of 1.5mm Textured Geomembrane

| Properties | Test Method | Test Value | Testing Frequency (minimum) |

Thickness mils (min. ave.) lowest individual for 8 out of 10 values lowest individual for any of the 10 values | D 5994 | nom. (-5%) -10% -15% | per roll |

| Asperity Height mils (min. ave.) | D 7466 | 0.40 mm | every 2nd roll (1) |

| Formulated Density (min. ave.) | D 1505/D 792 | 0.940 g/cc | 90,000 kg |

Tensile Properties (min. ave.) (2) yield strength break strength yield elongation break elongation | D 6693 Type IV | 22 kN/m 16 kN/m 12% 100% | 9,000 kg |

| Tear Resistance (min. ave.) | D 1004 | 187 N | 20,000 kg |

| Puncture Resistance (min. ave.) | D 4833 | 400 N | 20,000 kg |

| Stress Crack Resistance (3) | D 5397 (App.) | 500 hr. | per GRI GM10 |

| Carbon Black Content (range) | D 4218 (4) | 2.0-3.0 % | 9,000 kg |

Oxidative Induction Time (OIT) (min. ave.) (6) (a) Standard OIT — or — (b) High Pressure OIT | D 3895 D 5885 | 100 min. 400 min. | 90,000 kg |

Oven Aging at 85°C (6), (7) (a) Standard OIT (min. ave.) - % retained after 90 days — or — (b) High Pressure OIT (min. ave.) - % retained after 90 days | D 5721 D 3895 D 5885 | 55% 80% | per each formulation |

UV Resistance (8) D 7238 (a) Standard OIT (min. ave.) — or (b) High Pressure OIT (min. ave.) - % retained after 1600 hrs (10) | D 7238 D 3895 D 5885 | N.R. (9) 50% | per each formulation |

Product Advantages

Exceptional Durability: Made from high-density polyethylene (HDPE), our single-textured geomembrane offers outstanding resistance to corrosion, aging, and extreme environmental conditions.

Enhanced Performance: The unique textured surface provides excellent frictional properties, ensuring stability and effective soil movement control.

Chemical Resistance: Designed to withstand harsh chemicals, our geomembrane is ideal for applications such as red mud reservoir utilization projects, offering long-lasting protection against chemical erosion.

High Mechanical Strength: With superior tensile strength and puncture resistance, our geomembrane ensures robust performance and longevity in various applications.

Red Mud Reservoir Comprehensive Utilization Project

The comprehensive utilization project of red mud reservoirs refers to an initiative that aims to effectively manage and repurpose red mud, a byproduct generated from alumina refining processes. Red mud is known for its caustic and potentially hazardous nature due to the presence of alkaline substances and heavy metals.

The project typically involves the implementation of various technologies and methods to address environmental concerns associated with red mud, reduce its environmental impact, and extract valuable resources from it.

655660.webp)

Problems It Faced

1, Seepage Control: Red mud can contain corrosive and potentially harmful substances.

2, Chemical Erosion Resistance: It has the risk of chemical erosion caused by the alkaline nature of red mud.

3, Construction Efficiency: After the project is beginning, it needs to be completed in some required time.

Resolutions

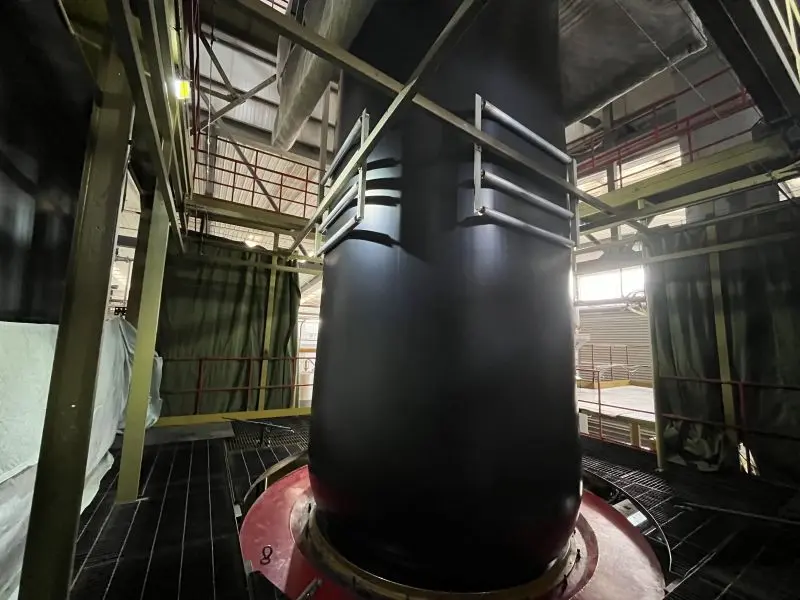

In the comprehensive utilization project of red mud reservoirs, the single-textured geomembrane has become an indispensable geosynthetic material, owing to its outstanding impermeability, resistance to chemical erosion, and ease of construction.

Its unique features make it a crucial component in ensuring the success of the project. It can perfectly solve the above problems.

1, Seepage Control: A single-textured geomembrane, with its superior impermeability, can act as an effective barrier to prevent seepage and protect the surrounding environment.

2, Chemical Erosion Resistance: The chemical resistance of the geomembrane helps mitigate the risk of chemical erosion caused by the alkaline nature of red mud, enhancing the overall stability of containment structures.

3, Construction Efficiency: The ease of construction provided by a single-textured geomembrane can contribute to the efficient implementation of the project, reducing the time and resources required for installation.

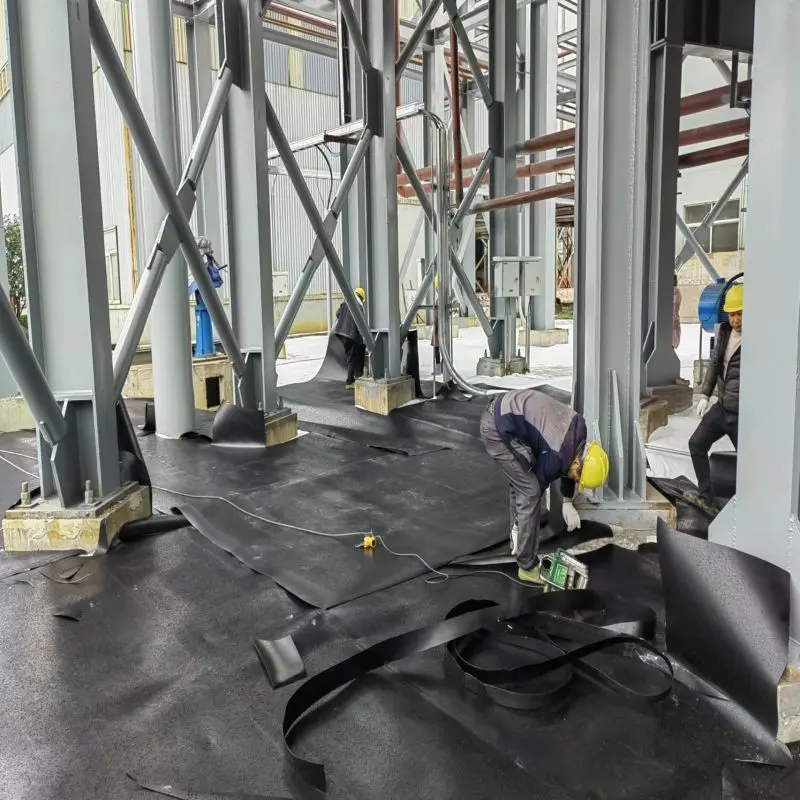

Successful Case

We were approached by a client for their comprehensive utilization project of a red mud reservoir. After a thorough assessment of the project,

we recommended the use of a 1.5mm single-textured geomembrane. Our team coordinated the welding installation of the geomembrane, and the construction process proceeded smoothly. The client expressed high satisfaction with the outcome. They are pleased with the efficiency of the installation and the performance of the 1.5mm geomembrane. We are delighted to have met and exceeded the client's expectations,here are some reasons why we choose 1.5mm single-textured geomembrane:

1, Outstanding Impermeability:

The 1.5mm single-textured geomembrane exhibits exceptional impermeability, effectively isolating hazardous substances in red mud, preventing seepage, and ensuring environmental safety within the project area.

2, Chemical Erosion Resistance:

The material of the geomembrane boasts superior chemical stability, offering excellent resistance to the chemicals present in red mud. This enhances the project's durability and long-term performance.

3, High Mechanical Strength:

The 1.5mm geomembrane demonstrates outstanding mechanical strength, capable of withstanding pressures and deformations that may occur during the project, ensuring the stability of the engineering structures.

4, Ease of Construction:

The easy-to-install nature of the 1.5mm single-textured geomembrane contributes to improved construction efficiency, reducing construction time and labor costs.

If you happen to encounter a similar challenge, we hope the above case can provide you with some reference, and if you have any questions, feel free to reach out to us. Our dedicated team is ready to offer you sound advice.

Providing excellent service and resolving every customer's issue is our commitment. We look forward to the opportunity of working with you.

Please don't hesitate to contact us. Meeting your needs is our priority.

Our Advantages of Producing Singele-textured Geomembrane

At present, our factory has the world's sole 10-meter-wide blow molding geomembrane production line, which also can do five-layer co-extrusion, dual-sided rough spray , nitrogen-assisted roughening. This cutting-edge facility positions us at the forefront of the industry, providing unmatched capabilities and ensuring the delivery of top-quality products to meet the diverse needs of our clients. now please follow me to our factory and let me introduce our 10-meter-wide blow molding geomembrane production line to you.

This picture shows where we put our raw materials.The main raw materials of geomembranes include: 96% Resin, 2-3% Carbon Black, 1% Other Additives. We put different raw materials in different tanks. We use 100% virgin raw materials to ensure our product quality.

This is our Computer Fully Automatic Feeding Machine. We use the world's most advanced automatic feeding machine control system, which ensure precise and accurate material loading, minimizing errors and waste. This precision contributes to higher-quality production.

We have three Computer Fully Automatic Feeding Machine. By offering precision, accuracy, and consistency in material dispensing, optimizing mixing ratios, minimizing waste, providing real-time monitoring, and aligning with quality assurance protocols, we can ensure you best quality products.

Here is the blow process. During this process it use an extruder to squeeze molten plastic into a tubular thin film, which is then expanded into a membrane through the introduction of air. In the preparation of blown film geomembranes, materials high-density polyethylene (HDPE) are employed. After extrusion through the machine, a plastic thin film is created. Simultaneously, gas is injected into the interior, causing it to expand into a tubular shape and ultimately forming the geomembrane.

This is stretching production process, where the primary principle involves stretching the extruded film to enhance its physical properties. The process includes material preparation, extrusion, inflation, cooling, and winding. The stretching imparts improved strength, tear resistance, and directional characteristics to the geomembrane, making it suitable for diverse engineering and environmental applications.

The cutting and winding process of blown film geomembranes involves trimming the extruded film into rolls. The fundamental principle includes precise cutting of the film at specified lengths, followed by winding onto rolls for convenient storage and transportation. This process ensures the production of neatly packaged geomembrane rolls ready for deployment in various engineering and environmental applications.

Contact Us

Discover the difference our 1.5mm single-textured geomembrane can make for your project. For more information or to discuss your specific needs, please contact us:

Haoyang Environmental Co., Ltd.

Phone: +8618853127527

Email: info@hygeosynthetics.com

Website: hygeosynthetics.com

Address: Yingbin Road, Dezhou(Yucheng)national Development Zones for New and High Technology industries Shandong Province, China

Partner with Haoyang Environmental Co., Ltd. for innovative, reliable, and sustainable geosynthetic solutions tailored to your environmental engineering challenges.

FAQ

Q1: What is the primary purpose of using a 1.5mm single-textured geomembrane in the Red Mud Reservoir Comprehensive Utilization Project?

The 1.5mm single-textured geomembrane is employed to provide superior impermeability, effectively isolating harmful substances in red mud, preventing seepage, and ensuring environmental safety within the project area.

Q2: How does the 1.5mm geomembrane contribute to the overall environmental protection goals of the project?

The geomembrane acts as a reliable barrier, preventing the leaching of contaminants from red mud into the surrounding environment. Its impermeable nature enhances environmental protection and containment, aligning with the project's sustainability objectives.

Q3: What are the advantages of choosing a 1.5mm thickness for the geomembrane in this project?

The 1.5mm thickness provides an optimal balance between material strength and flexibility, ensuring effective containment while allowing for ease of installation. It meets the project's technical specifications and safety requirements.

Q4: Can the 1.5mm single-textured geomembrane resist the corrosive nature of red mud?

Yes, the geomembrane's material composition includes corrosion-resistant properties, making it highly effective in resisting the corrosive elements present in red mud. This ensures the long-term durability of the containment system.

Q5: How does the 1.5mm geomembrane contribute to the efficient utilization of the red mud reservoir?

The geomembrane's impermeability and resistance to chemical erosion play a crucial role in containing red mud effectively. This containment facilitates the implementation of comprehensive utilization processes, such as resource recovery and reduced environmental impact, contributing to the project's success.

503.webp)

759.webp)

776.webp)