1、Product introduction

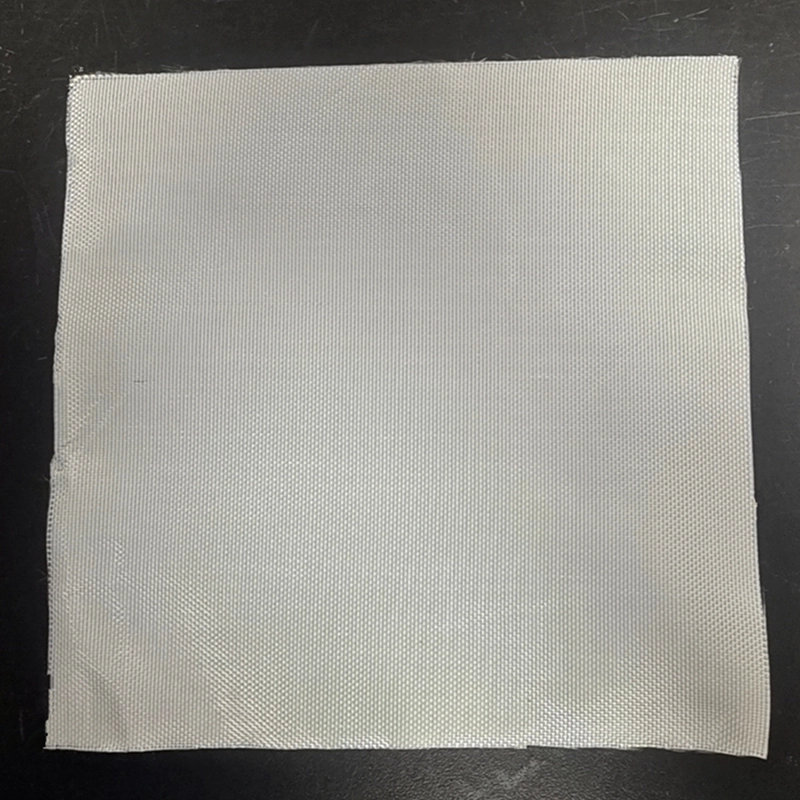

Filament woven geotextiles are fabrics woven by two groups of silk shuttle, and the varieties are divided into single-layer woven geotextiles (also known as geofilter cloth), double-layer geotextiles (also known as geomembrane bag cloth) and woven impermeable cloth according to their use. It is mainly made of high strength and low extension polypropylene, polyester and other synthetic fiber filaments.

2、How is filament woven geotextiles produced?

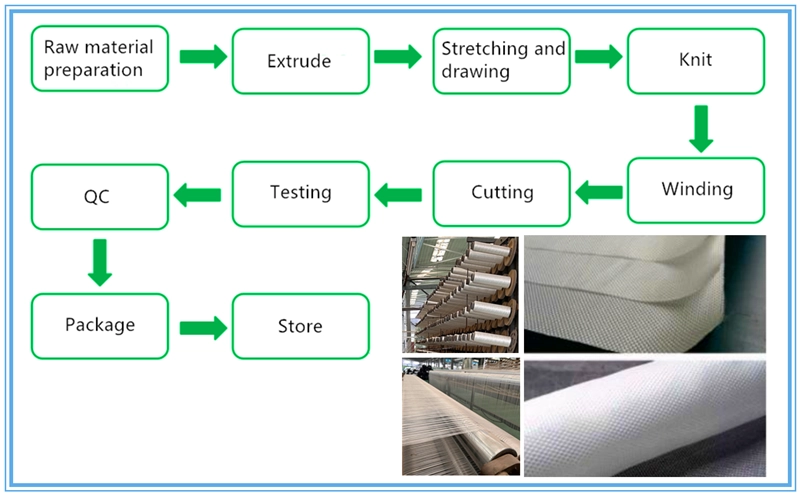

Production Process:

The production process of filament woven geotextiles is roughly as follows:

(1) Raw material preparation: usually polypropylene, polyester and other particles are fed into the extruder.

(2) Extrusion: In the extruder, the raw material particles are heated and extruded into a molten liquid.

(3) Stretch drawing: the liquid is poured into the mold for cooling and stretching into wire, so that it becomes a very fine filament. These threads help weave and strengthen geotextiles.

(4) Weaving: the filament is cross-woven through the braiding machine. This process forms a strong fabric structure in which tough filaments are interwoven to form the structure of the geotextile. The gap of filament woven geotextile has a larger gap than that of non-woven needled filament, which is also the biggest difference between the two.

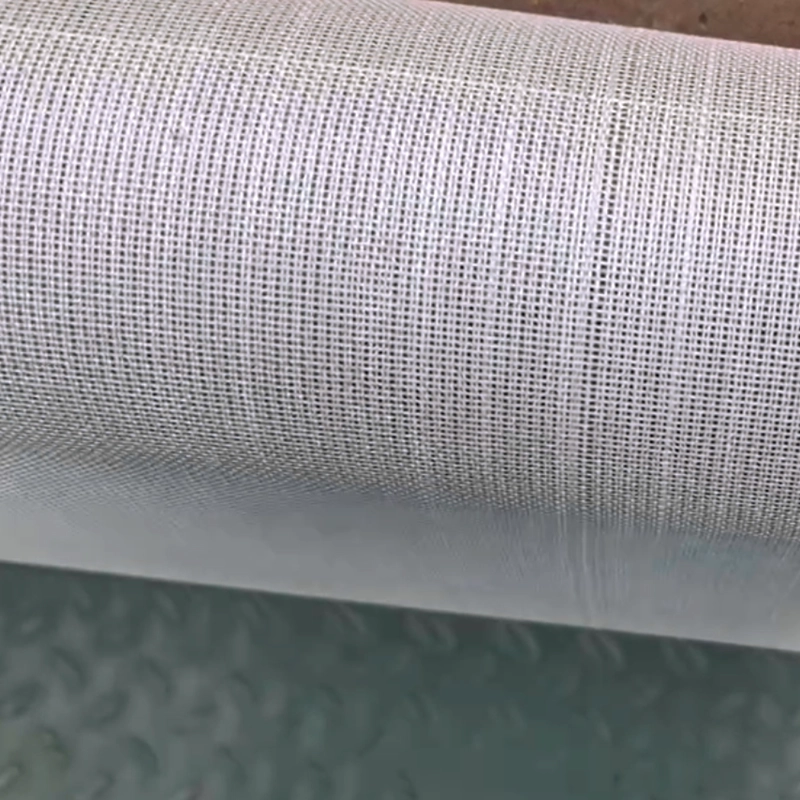

(5) Winding cutting: After weaving is completed, the geotextile is rolled or cut to the appropriate size and length. Filament woven geotextiles of different widths and lengths can be cut according to requirements.

(6) Inspection and quality control: the geotextile factory after sampling inspection by the company's testing center, in line with national standards and requirements. Tests typically include tensile strength, thickness uniformity, and braiding quality.

(7) Packaging and storage: the geotextile that has passed the inspection is properly packaged and ready for sale or storage. They are usually stored in volume form for easy transportation and use.

These steps constitute the production process of filament woven geotextiles, ensuring that the final product has the required strength, durability and quality standards.

3、Filament woven geotextile internal quality technical requirements:

The internal quality requirements of geosynthetic filament woven geotextiles are fully in line with the national standard JBT17640-2008 promulgated by the General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China and the Standardization Administration of the Country.

No. | Item | Unit | Index | ||||||||||

Nominal breaking strength | Kn/m | 30 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 | |

1 | Radial breaking strength | Kn/m | ≥ 30 | ≥ 50 | ≥ 65 | ≥ 80 | ≥ 100 | ≥ 120 | ≥ 140 | ≥ 160 | ≥ 180 | ≥ 200 | ≥ 250 |

2 | Zonal breaking strength | Kn/m | ≥Radial breaking strength*0.7 | ||||||||||

3 | Nominal strength elongation | % | ≤Radial 35;Zonal30 | ||||||||||

4 | CBR bursting strength | Kn

| ≥ 2.0 | ≥ 4.0 | ≥ 6.0 | ≥ 8.0 | ≥ 10.5 | ≥ 13.0 | ≥ 15.5 | ≥ 18.0 | ≥ 20.5 | ≥ 23.0 | ≥ 28.0 |

5 | Equivalent aperture O90(O95) | mm | 0.05~0.50 | ||||||||||

6 | Vertical permeability coefficient | cm/s | K*(10-2~10-5),K=1.0~9.9 | ||||||||||

7 | Width deviation | % | -1.0 | ||||||||||

8 | Mold bag filling thickness deviation | % | ±8 | ||||||||||

9 | Mold bag length, width deviation | % | ±2 | ||||||||||

10 | Sewing strength | Kn/m | ≥Nominal breaking strength*0.5 | ||||||||||

11 | Warp and weft tear strength | Kn

| ≥ 0.4 | ≥ 0.7 | ≥ 1.0 | ≥ 1.2 | ≥ 1.4 | ≥ 1.6 | ≥ 1.8 | ≥ 1.9 | ≥ 2.1 | ≥ 2.3 | ≥ 2.7 |

12 | Mass deviation per unit area | % | -5 | ||||||||||

4、Field of use of filament woven geotextiles:

(1) For reinforcement in the backfill of the retaining wall, or for anchoring the panel of the retaining wall. Construction of wraparound retaining walls or abutments.

(2) Strengthen the flexible pavement, repair the cracks on the road, and prevent the pavement from reflecting cracks.

(3) Increase the stability of gravel slope and reinforced soil to prevent soil erosion and freezing damage at low temperatures.

(4) The isolation layer between the road ballast and the roadbed, or the isolation layer between the roadbed and the soft foundation.

(5) The isolation layer between artificial soil filling, rockfill or material field and the foundation, the isolation between different frozen soil layers, the filter and the reinforcement effect.

(6) The filter layer of the initial upstream dam surface of the ash dam or tailings dam, and the filter layer of the drainage system in the backfill soil of the retaining wall.

(7) The filter layer around the drainage dark pipe or the gravel drainage dark ditch.

(8) The filter layer of water Wells, relief Wells or baroclinic pipes in water conservancy projects.

(9) Isolation layer of geotextile between road, airport, railway track slag and artificial rockfill and foundation.

(10) The earth dam internal vertical or horizontal drainage, buried in the soil to dissipate the void water pressure.

(11) Drainage behind impermeable geomembrane or under concrete protection in earth DAMS or earth embankments.

(12) Eliminate water seepage around the tunnel, reduce the external water pressure borne by the lining and water seepage around the buildings.

(13) Drainage of the foundation of the artificially filled ground sports ground.

(14) Roads (including temporary roads) are used to strengthen weak foundations in projects such as railways, embankments, earth-rock DAMS, airports and sports grounds.

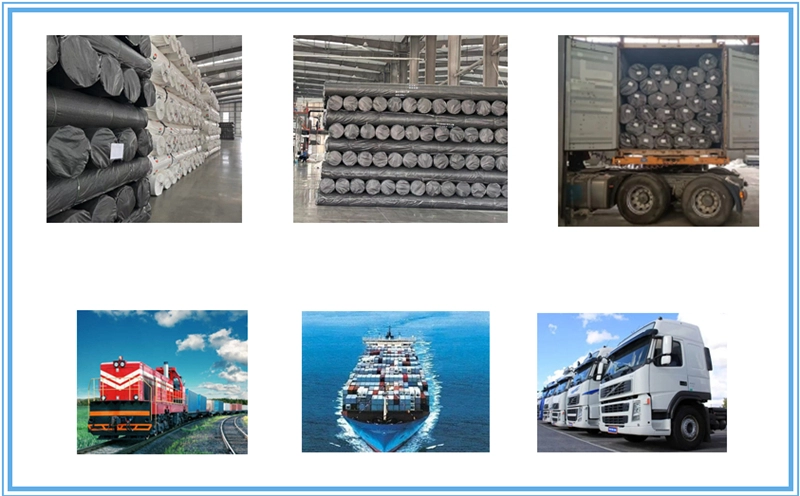

5、Mode of transport

We provide our customers with a variety of transportation methods for remote delivery of geomaterials, ensuring that products reach their destinations safely and quickly. Our range of transport options includes land, sea and air transport to meet the different needs and project requirements of our customers.

6、FAQ

Q1: What are the different specifications of geotextiles? What are their physical performance indicators?

A1: We offer geotextiles in a variety of sizes, including different weights, widths and tensile strength. Specific indicators such as tensile strength, permeability, etc., vary according to different specifications. You are advised to select appropriate specifications based on project requirements.

Q2: In what projects is this geotextile suitable? Are there any similar projects?

A2: Filament woven geotextiles are widely used in roadbed reinforcement, slope protection, river embankment reinforcement and other fields. We can provide previous engineering cases to demonstrate the application effect of geotextiles in different projects.

Q3: What is the performance of geotextile under different environmental conditions? Can it adapt to different soil conditions?

A3: Our geotextiles have good adaptability in different environments, can be applied to different types of soil and climate conditions, and has good weather resistance.

Q4: How to install and fix geotextiles? Does it require special maintenance?

A4: When installing, it is usually necessary to lay geotextile on the flat base, and use the corresponding fixing method to fix. As for maintenance, regular checking and keeping it clean helps extend service life.

Q5: What about the price of the product? What is the lead time?

A5: Price depends on specifications and order quantity, we offer competitive price. Delivery times vary depending on order volume and location, but we will do our best to meet your timing requirements.

The following are other geotechnical products of our company, you can click on the link to view.

https://hygeosynthetics.com/White-waterproof-filament-non-woven-geotextile-for-tunnel-LS_2.html

![]() 200g Staple fiber non-woven geotextile.pdf

200g Staple fiber non-woven geotextile.pdf

![]() 300g PET geotextiles test report.pdf

300g PET geotextiles test report.pdf

503.webp)

759.webp)