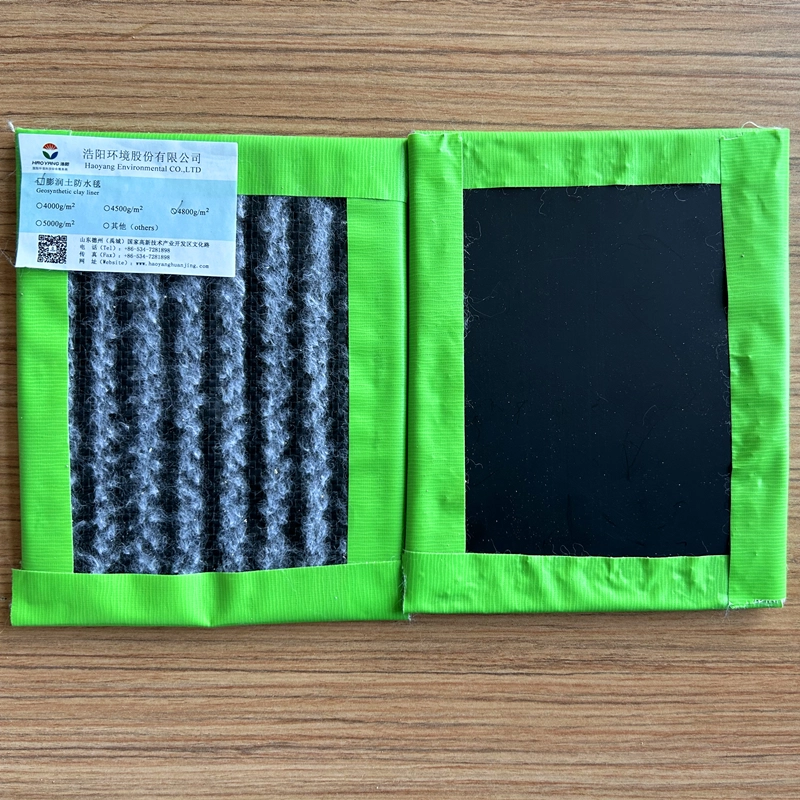

Leachate Collection System Landfill Liner Material – Geosynthetic Clay Liner Waterproof Blanket

Haoyang Environmental Co., Ltd. presents its high-performance Geosynthetic Clay Liner (GCL) Waterproof Blanket, specially designed for leachate collection systems in landfill liner applications. Engineered with precision, our GCL combines a layer of natural sodium bentonite encapsulated between geotextiles or geomembranes, delivering exceptional waterproofing and durability. With our commitment to innovation and sustainability, Haoyang ensures reliable and eco-friendly solutions for effective landfill management.

Sodium Bentonite Composite Waterproof Blanket (GCL)

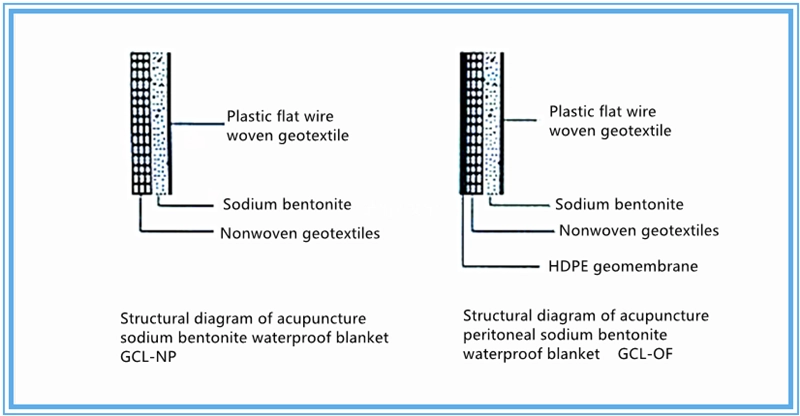

Sodium bentonite composite waterproof blanket (GCL) is a new type of geosynthetic material, which can be specially used for impermeable geosynthetic materials such as artificial lake water feature, landfill, underground garage, roof garden, pool, oil depot and chemical plant. The high expansion sodium bentonite is filled between the composite plastic flat silk geotextile and non-woven fabric, and the bentonite particles can not flow unidirectional by acupuncture method, and a uniform and high density rubber waterproof layer is formed in the pad when it meets water to effectively prevent water leakage. Bentonite waterproof blanket not only has all the characteristics of geotechnical materials, but also has excellent waterproof (seepage) performance. It is a kind of impermeable lining between GCL and polymer material (geomembrane).

The waterproof mechanism is that the sodium-based granule bentonite used in the bentonite waterproof blanket expands more than 24 times when it meets water, thus forming a uniform colloidal system, which has the characteristics of high viscosity and low filtration. Under the constraint of two layers of geotextile, bentonite expanded from disorder to order. The result of continuous expansion of water is that the bentonite layer itself becomes dense, thus having a waterproof effect.

Our company mainly produces needled sodium-based swelling moisturizing waterproof blanket and needled coated sodium-based swelling moisturizing waterproof blanket.

GCL-NP and GCL-OF geosynthetic bentonite waterproof blanket

How is Sodium Bentonite Waterproof Blanket Produced?

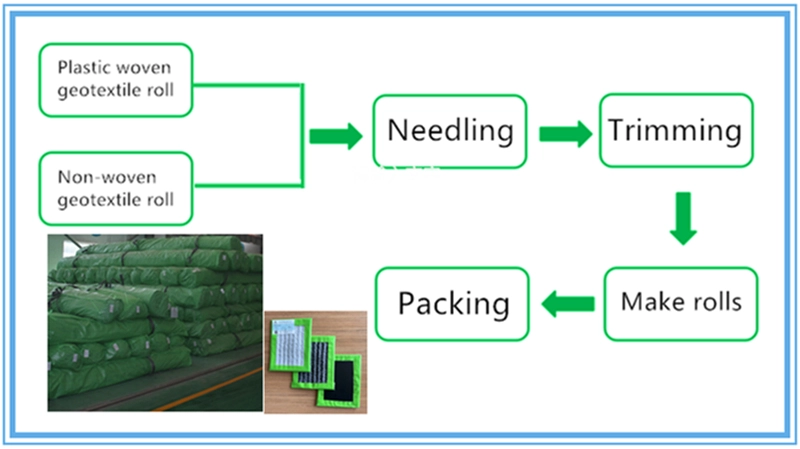

Production Process:

Specific operating procedures:

(1) Prepare the woven fabric and non-woven fabric in advance, put them in your position, and let the woven fabric and non-woven fabric two layers pass through the acupuncture part;

(2) Prepare the bentonite to the feed bucket, and transport the bentonite to the horizontal conveyor by the angled cage to control the feeding speed;

(3) The bentonite flow rate is adjusted by adjusting the position of the lower plate and cylinder;

(4) The needling machine thrusting and pulling the three through the hook barbed needle at a high speed to become a body intertwined with each other, in which the spindle and the net roller linkage drive, the barbed waterproof blanket transported to the next process;

(5) Cut the GCL waterproof blanket vertically and horizontally and roll it, adjust the meter to make it reach the length and automatically cross cut and check the package.

Specification

| Specification | Details |

|---|---|

| Product Name | Geosynthetic Clay Liner (GCL) Waterproof Blanket |

| Material Composition | Natural Sodium Bentonite Encased in Geotextiles or Geomembranes |

| Bentonite Thickness | 3mm |

| Geotextile Type | Woven or Non-Woven (Customizable) |

| Width (Roll) | Up to 6 meters |

| Length (Roll) | Up to 40 meters (Adjustable per project) |

| Weight | Customized based on specifications |

| Permeability | ≤ 5 x 10⁻¹² m/s (Excellent Impermeability) |

| Shear Strength | ≥ 24 kN/m (High Durability) |

| Swelling Index | ≥ 24 mL/2g (Strong Swelling Capability) |

| Puncture Resistance | ≥ 500 N (Robust Structure) |

| Tensile Strength | ≥ 15 kN/m |

| Environmental Resistance | Resistant to Chemicals and UV Degradation |

| Installation Temperature | -30°C to +85°C |

| MOQ | 1000 m² |

| Applications | Landfill Liners, Mining Sites, Industrial Waste Containment, Environmental Remediation |

For additional details or customized specifications, please contact us.

Product Advantages

Superior Waterproofing: The GCL integrates bentonite's natural swelling properties to form an impermeable barrier against liquids and gases.

Durable Performance: Engineered for long-term use, the material resists chemical degradation, punctures, and environmental stress.

Eco-Friendly Solution: Manufactured using natural materials, the GCL minimizes environmental impact, making it a sustainable choice.

Ease of Installation: Lightweight and flexible, the material can be installed quickly, reducing project time and costs.

Cost-Effective: Its high performance and minimal maintenance needs provide excellent value over its lifecycle.

Applications

The Geosynthetic Clay Liner Waterproof Blanket is ideal for:

Landfill Liners and Caps: Provides a reliable barrier to prevent leachate leakage into the soil and groundwater.

Mining Sites: Acts as a liner for tailing ponds and reservoirs to control seepage.

Industrial Waste Containment: Effective for hazardous and non-hazardous waste storage systems.

Environmental Remediation: Suitable for soil sealing in polluted areas.

Bentonite Waterproof Blanket Construction Method

(1) The bentonite waterproof blanket material has a large weight, and it is appropriate to use a shovel with waterproof blanket lifting tools to carry and lay.

(2) The connection of bentonite waterproof blanket material adopts the method of lap bonding.

(3) When the bentonite waterproof blanket is laid on the slope of more than 10%, the number of overlaps along the long direction of the slope should be minimized, and the bentonite cushion on the slope must exceed the slope foot line by more than 1500mm. D. We will lay the bentonite waterproof blanket in strict accordance with the design drawing submitted to the supervision engineer, unless required by the owner or the supervisor.

(4) Any equipment used for laying bentonite waterproof blankets shall not be driven on geosynthetic materials that have been laid. When installing the bentonite waterproof blanket, the outdoor air temperature should not be lower than 0℃ or higher than 40℃.

(5) All exposed edges of the bentonite waterproof blanket must be immediately pressed with sandbags or other heavy objects to prevent the bentonite waterproof blanket from being blown by the wind or being pulled out of the surrounding anchoring ditch. The bentonite waterproof blanket cannot be unrolled in windy weather to prevent being blown up by the wind.

(6) The laying method of the bentonite waterproof blanket must ensure that the bentonite waterproof blanket is in direct contact with the underlying foundation to eliminate wrinkles. Any folding, folding or arching may cause the same to happen to other geotechnical materials in the soil layer. In order to avoid folding, folding and arching, we will eliminate these problems by re-laying or cutting and repairing the bentonite waterproof blanket according to the requirements of the technical instructions.

(7) Bentonite waterproof blanket equipment must be approved by the supervision engineer to use, do not allow the use of unprotected razor or "fast knife". I. The construction equipment that may damage the bentonite blanket cannot directly act on the bentonite blanket. The feasible laying method is to push the earth backwards and spread out the bentonite blanket at the front of the lifting bulldozer. If the soiler leaves a car mark on the foundation soil, it should be restored before the laying work continues.

(8) When laying the bentonite blanket, minimize the dragging of the bentonite blanket on the foundation, so as not to cause damage to the contact surface between the bentonite blanket and the ground. If necessary, a temporary layer of geotextile can be added to the ground to reduce the damage caused by friction during the laying of the bentonite blanket.

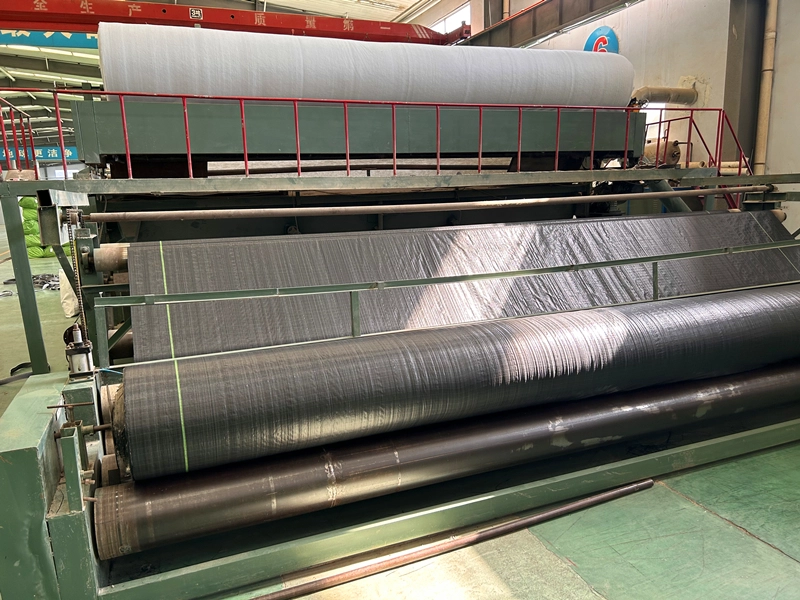

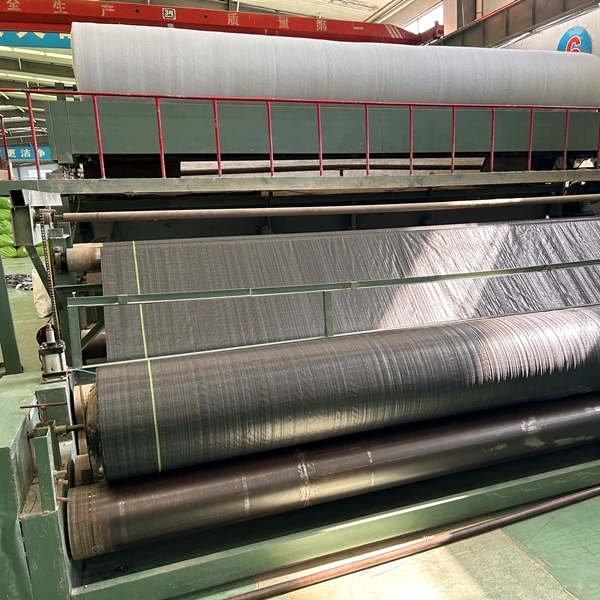

Production workshop

Welcome to our advanced production workshop! This is the center of precision manufacturing in our company. The following are some pictures of our advanced production equipment and high-quality products, as well as the workshop pictures implemented in accordance with the 6S standard: the equipment floor is clean, the product equipment is placed reasonably, and the ground line is clear and clear.

These pictures show our company's production equipment and some of our products, demonstrating our advanced production process and precision manufacturing capabilities.

Company Advantages

Proven Expertise: Established in 2008, Haoyang has over 15 years of experience in geosynthetics and environmental engineering.

Certifications and Recognitions: ISO 9001, ISO 14001, and OHSAS 18001 certifications ensure top-notch quality, along with recognition as a "Shandong Enterprise Technology Center."

Innovative R&D: Equipped with three invention patents and 32 utility model patents, our dedicated R&D team consistently delivers cutting-edge solutions.

Sustainable Approach: We focus on creating products that meet environmental governance and pollution control standards.

Global Reach: Trusted by clients worldwide, Haoyang’s products excel in diverse environmental conditions.

Let Haoyang Environmental Co., Ltd. partner with you to create a sustainable and efficient leachate collection system. Reach out to us today for a customized solution tailored to your needs!

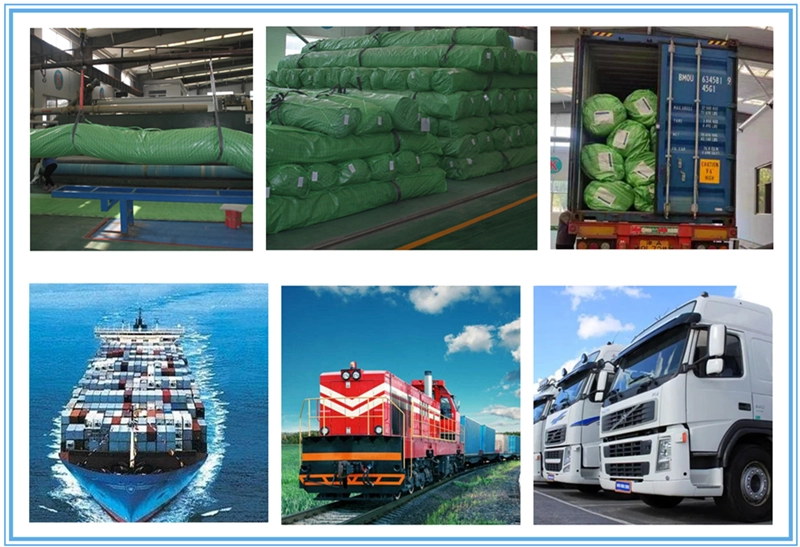

Mode of Transport

We provide our customers with a variety of transportation methods for remote delivery of geomaterials, ensuring that products reach their destinations safely and quickly. Our range of transport options includes land, sea and air transport to meet the different needs and project requirements of our customers.

FAQ

Q1: Where is your factory located? How do I get there?

A1: Our factory is located in Yucheng High-tech Development Zone, Dezhou City, Shandong Province. You can take a plane to Jinan Yaoqiang International Airport, and then we will pick you up.

Q2: What is the lead time?

A2: Usually 5-10 working days after receiving the deposit.

Q3: How do you guarantee the quality testing of your products?

A3: The testing center of Haoyang Environmental Co., Ltd. obtained the CNAS Laboratory accreditation Certificate, certificate number L11088. Each batch of products will undergo rigorous testing before leaving the factory.

Q4: What is the main material used for bentonite waterproof blanket? Are there any environmentally harmful ingredients?

A4: Our products mainly use bentonite and environmentally friendly additives, no harmful ingredients to the environment, in line with national environmental standards.

Q5: Does product installation require special technology or equipment? Are there construction guides and video tutorials?

A5: We provide detailed construction guidelines and can provide construction videos, which is relatively easy to install and requires no special technology or equipment.

Q6: What about product quality control and packaging details? Is there a product warranty?

A6: We strictly implement the quality control process, product packaging meets the transportation needs, and provide product warranty period.

The following is our company's other geotechnical products, you can click the link to understand.

503.webp)

759.webp)

927.webp)

109.webp)