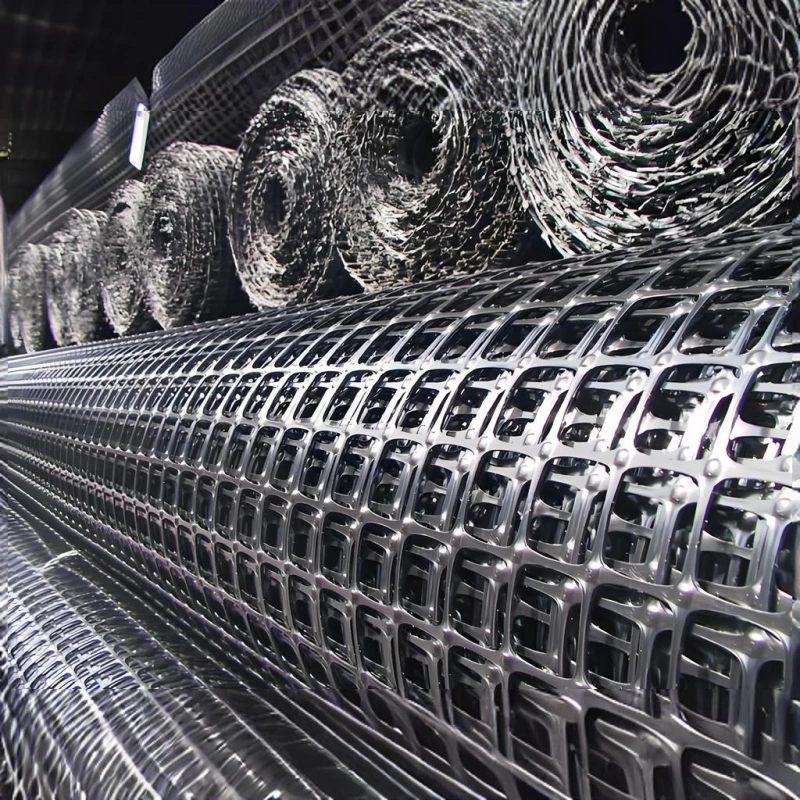

Geogrid Fabric for Retaining Walls: Product Overview

Introduction

440374.webp)

Geogrid fabric is a crucial component in the construction of retaining walls, providing essential reinforcement to ensure stability and longevity. Designed to enhance the structural integrity of retaining walls, geogrid fabric is a geosynthetic material made from high-strength polymers such as polypropylene or polyester. It is specifically engineered to interlock with the surrounding soil, creating a unified structure that effectively resists lateral earth pressures.

Applications in Retaining Walls

When used in retaining walls, geogrid fabric plays a pivotal role in soil reinforcement. It helps distribute the load more evenly across the wall, preventing soil slippage and reducing the risk of wall failure. The geogrid fabric is typically installed in layers between soil and backfill, binding the soil together and increasing the overall strength of the wall. This makes it particularly effective for walls that need to support heavy loads or are built on unstable ground.

Benefits of Geogrid Fabric for Retaining Walls

Enhanced Stability:

Load Distribution: Geogrid fabric distributes the weight and pressure across the retaining wall, preventing localized stress points that could lead to failure.

Soil Interlock: The open structure of the geogrid allows soil particles to interlock, creating a stronger, more cohesive structure that resists shifting and settling.

Improved Durability:

Long-Lasting Support: Geogrid fabrics are highly durable and resistant to environmental factors such as UV radiation, chemical exposure, and biological degradation, ensuring long-term performance.

Erosion Control: By stabilizing the soil behind the wall, geogrid fabric reduces erosion, preventing the loss of soil and maintaining the wall's integrity over time.

Cost-Effective Solution:

Reduced Material Costs: The use of geogrid fabric can reduce the need for additional materials, such as concrete or steel, by providing effective reinforcement with a lighter, more flexible material.

Labor Savings: Easy to install, geogrid fabric simplifies the construction process, reducing labor time and costs.

Versatility:

Adaptable to Various Soil Types: Geogrid fabric is effective in different soil conditions, including clay, silt, sand, and gravel, making it a versatile solution for a wide range of projects.

Compatibility with Different Wall Types: It can be used with various types of retaining walls, including gravity walls, cantilever walls, and anchored walls.

Technical Specifications

Material Composition: High-strength polymers such as polypropylene (PP) or polyester (PET).

Tensile Strength: Available in different tensile strengths, typically ranging from 20 kN/m to 200 kN/m, depending on project requirements.

Aperture Size: Common aperture sizes range from 20 mm to 60 mm, designed to optimize soil interlock and reinforcement.

Roll Dimensions: Geogrid fabric typically comes in rolls with widths ranging from 1 m to 5 m and lengths from 50 m to 100 m, allowing for easy handling and installation.

UV Resistance: Treated for UV resistance to ensure durability and performance in exposed environments.

Temperature Resistance: Suitable for a wide range of temperatures, ensuring performance in various climatic conditions.

Here is a table displaying the technical specifications for Geogrid Fabric:

| Specification | Details |

|---|---|

| Material Composition | High-strength polymers (Polypropylene, Polyester) |

| Tensile Strength | 20 kN/m to 200 kN/m |

| Aperture Size | 20 mm to 60 mm |

| Roll Width | 1 m to 5 m |

| Roll Length | 50 m to 100 m |

| UV Resistance | UV stabilized for outdoor durability |

| Temperature Resistance | Suitable for a wide range of temperatures |

| Elongation at Break | Typically 10% to 15% |

| Chemical Resistance | Resistant to common chemicals and soil conditions |

| Biological Resistance | Resistant to mold, mildew, and insect damage |

| Installation Method | Simple unrolling and placement, typically in layers |

This table provides a clear overview of the key technical specifications of Geogrid Fabric, making it easier to understand its capabilities and applications.

Geogrid fabric is an essential material for enhancing the stability and durability of retaining walls. Its ability to reinforce soil, distribute loads, and prevent erosion makes it an invaluable tool in civil engineering and construction. With its versatile applications, cost-effectiveness, and long-lasting performance, geogrid fabric is the ideal choice for ensuring the success of retaining wall projects. Whether you're constructing a small garden wall or a large commercial retaining structure, geogrid fabric provides the reinforcement needed to ensure a safe and stable wall that will stand the test of time.

How to Install Geogrid Fabric for Retaining Walls

Installing Geogrid Fabric for retaining walls is a crucial process that enhances the stability and longevity of the wall. Here's a step-by-step guide on how to properly install Geogrid Fabric:

1. Prepare the Site

Excavation: Begin by excavating the area where the retaining wall will be built. Ensure that the base is level and properly compacted to provide a solid foundation.

Wall Base Preparation: Install the base layer of the retaining wall using suitable materials, such as gravel or crushed stone. Compact the base thoroughly to ensure stability.

2. Lay the First Course of Blocks

Install the First Row: Place the first row of retaining wall blocks on the prepared base. Make sure the blocks are level and properly aligned.

Check Alignment: Use a level to ensure the blocks are perfectly horizontal. Proper alignment is crucial for the overall stability of the wall.

3. Install the Geogrid Fabric

Position the Geogrid: Unroll the Geogrid Fabric and cut it to the required length. The fabric should extend from the front of the retaining wall block to the specified length into the backfill area.

Lay the Geogrid: Place the Geogrid Fabric on top of the first course of blocks, ensuring that it is taut and free of wrinkles. The fabric should extend evenly across the length of the wall.

Secure the Geogrid: Pull the fabric tightly and secure it by placing the next course of blocks on top. This will hold the Geogrid in place as you continue building the wall.

4. Backfill Over the Geogrid

Add Backfill Material: After securing the Geogrid, backfill the area behind the retaining wall with suitable material, such as gravel or compacted soil. Spread the backfill evenly over the Geogrid.

Compact the Backfill: Use a compactor to firmly compact the backfill material. Proper compaction is essential to ensure that the Geogrid provides effective reinforcement.

5. Continue Building the Wall

Add Additional Courses: Continue adding additional rows of retaining wall blocks. Repeat the process of installing the Geogrid Fabric and backfilling after every 1-2 courses of blocks, depending on the design requirements.

Overlap the Geogrid (if necessary): If multiple layers of Geogrid are required, overlap the layers by at least 6 inches to ensure continuous reinforcement.

6. Final Steps

Complete the Wall: Finish the retaining wall by installing the final course of blocks and capping units, if applicable.

Final Compaction: Perform a final compaction of the backfill to ensure that everything is properly settled.

7. Inspection and Quality Control

Check for Proper Installation: Ensure that the Geogrid is correctly installed without any visible gaps, folds, or wrinkles.

Inspection: Inspect the entire retaining wall structure to ensure that it meets the design specifications and is securely reinforced with Geogrid Fabric.

Conclusion

Installing Geogrid Fabric in retaining walls is a straightforward but essential process that significantly enhances the wall's stability and lifespan. By carefully following the steps outlined above, you can ensure a successful installation that effectively reinforces the soil and prevents erosion, providing long-term stability for your retaining wall.

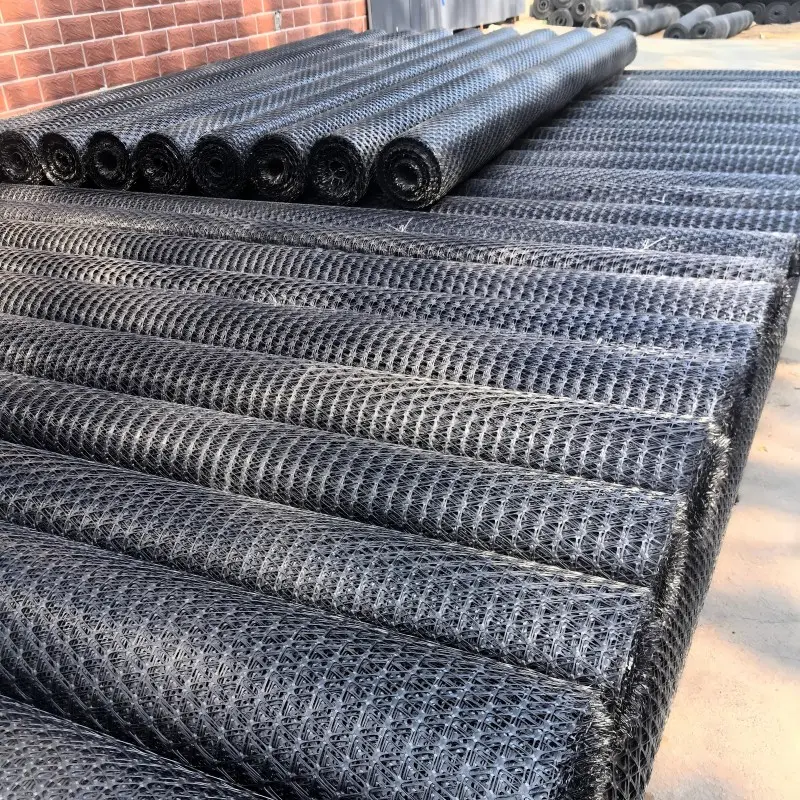

How to Make Geogrid Fabric

262777.webp)

Geogrid fabric is a type of geosynthetic material used primarily for soil reinforcement in construction projects such as retaining walls, roadbeds, and embankments. The manufacturing process involves several key steps to ensure the material's strength, durability, and performance. Here’s a detailed overview of how Geogrid Fabric is made:

1. Selection of Raw Materials

Polymers: The primary raw materials used to make geogrid fabric are high-strength polymers, such as polypropylene (PP) or polyester (PET). These materials are chosen for their tensile strength, durability, and resistance to environmental factors.

Additives: Stabilizers, UV inhibitors, and other additives are mixed with the polymers to enhance the geogrid’s durability, especially for outdoor applications where the material is exposed to sunlight and other environmental conditions.

2. Extrusion Process

Polymer Extrusion: The selected polymer, mixed with the necessary additives, is heated and extruded through a die to form a continuous sheet of plastic. This sheet serves as the base material for the geogrid.

Sheet Formation: The extruded plastic sheet is formed into a uniform thickness to meet the specific design requirements of the geogrid.

3. Punching and Drawing

Punching: The extruded sheet is passed through a punching machine, which creates a pattern of holes or apertures in the material. The pattern and size of these holes are crucial for the geogrid’s performance, as they allow for interlocking with soil particles.

Drawing (Stretching): After punching, the sheet is stretched in both the machine and cross-machine directions. This process, known as biaxial stretching, aligns the polymer molecules, significantly enhancing the tensile strength of the geogrid fabric. For uniaxial geogrids, the sheet is stretched in only one direction.

4. Heat Setting

Stabilization: The stretched geogrid is then subjected to heat setting, a process that stabilizes the material and locks in the molecular orientation achieved during stretching. This step ensures that the geogrid maintains its strength and shape during use.

5. Finishing

Trimming and Cutting: After heat setting, the geogrid fabric is trimmed to the desired width and length. The edges are also finished to prevent fraying or unraveling.

Inspection: The geogrid undergoes a thorough inspection to check for any defects or inconsistencies in the material. Quality control tests, such as tensile strength testing, are performed to ensure that the product meets the required specifications.

6. Rolling and Packaging

Rolling: The finished geogrid fabric is rolled into large rolls for easy transportation and handling. The roll size typically varies depending on the intended application and customer requirements.

Packaging: The rolls are packaged and labeled, often with protective wrapping to prevent damage during storage and transportation.

7. Quality Control

Testing: Before shipping, the geogrid fabric undergoes rigorous testing to ensure it meets industry standards for tensile strength, elongation, and environmental resistance.

Certification: Geogrids are often certified according to specific industry standards, such as ASTM or ISO, to ensure they are suitable for use in civil engineering applications.

Conclusion

The manufacturing process of Geogrid Fabric involves careful selection of raw materials, precise extrusion, punching, stretching, and finishing techniques to produce a material that is strong, durable, and effective in reinforcing soil structures. The resulting geogrid fabric is essential for a wide range of construction applications, providing long-lasting support and stability to various types of infrastructure projects.

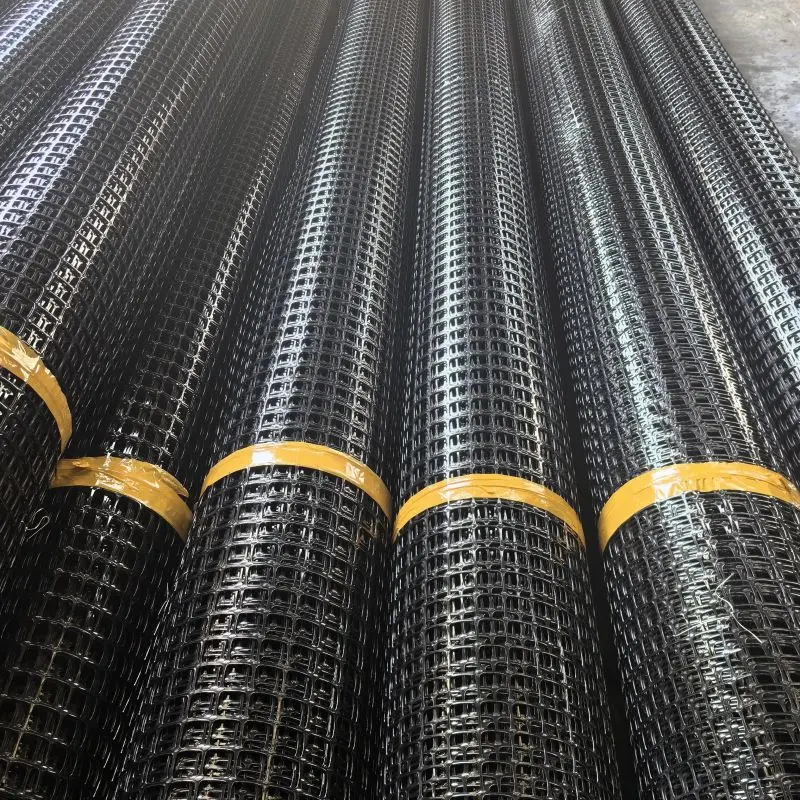

Haoyang: Your Trusted Geogrid Fabric Manufacturer

Haoyang is a leading manufacturer of Geogrid Fabric, specializing in providing high-quality solutions for retaining walls. With a commitment to excellence, we offer wholesale Geogrid Fabric designed to enhance the stability and durability of various construction projects. Our products are engineered using advanced materials and technology, ensuring superior performance in reinforcing soil structures and preventing erosion.

At Haoyang, we understand the importance of reliable and durable materials in construction, which is why our Geogrid Fabric is crafted to meet the highest industry standards. Whether you’re working on a large infrastructure project or a smaller landscaping job, Haoyang is your go-to source for Geogrid Fabric that delivers exceptional results. Partner with us for all your geosynthetic needs and experience the quality and reliability that sets us apart in the market.

The price of Geogrid Fabric for retaining walls can vary based on several factors, including the material, tensile strength, aperture size, roll dimensions, and the supplier. Here is a general overview of the typical price range:

| Specification | Details | Estimated Price (USD per square meter) |

|---|---|---|

| Material | Polypropylene (PP), Polyester (PET) | $0.50 - $2.00 |

| Tensile Strength | 20 kN/m to 100 kN/m | $0.60 - $1.50 |

| Tensile Strength | 100 kN/m to 200 kN/m | $1.50 - $3.00 |

| Aperture Size | 20 mm to 40 mm | $0.50 - $1.50 |

| Aperture Size | 40 mm to 60 mm | $1.00 - $2.50 |

| Roll Width | 1 m to 5 m | Typically included in square meter pricing |

| Roll Length | 50 m to 100 m | Typically included in square meter pricing |

| UV and Chemical Resistance | Standard for outdoor applications | Typically included in square meter pricing |

Factors Affecting Price

If you want to get factory price, please contact our experts, who will give you detailed solution and factory price.

503.webp)

759.webp)