This article explores the role of geogrids in slope stabilization, their benefits, and the applications that make them an indispensable tool in modern engineering.

Understanding Geogrids

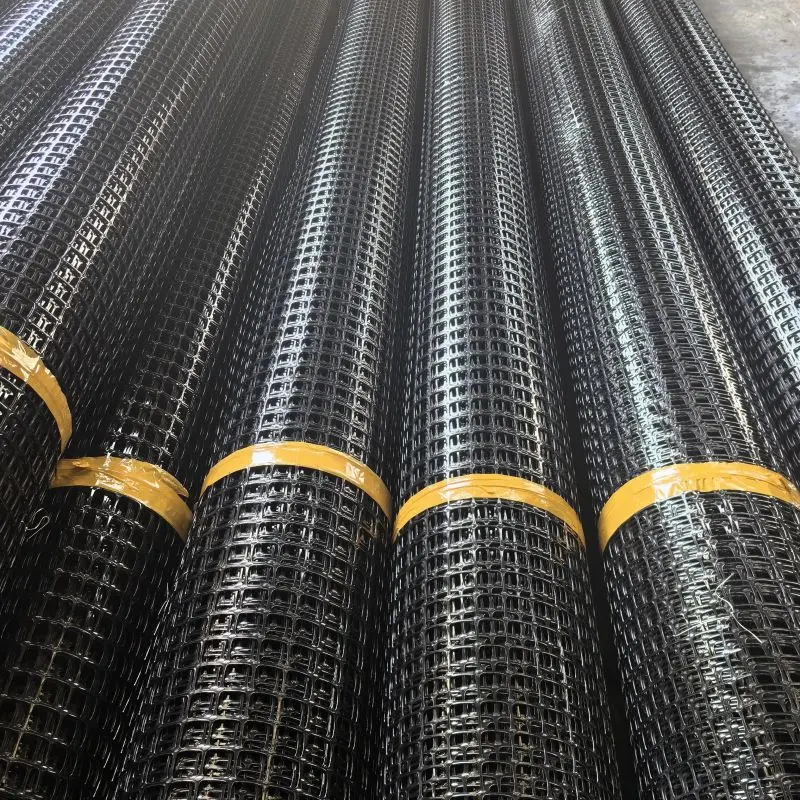

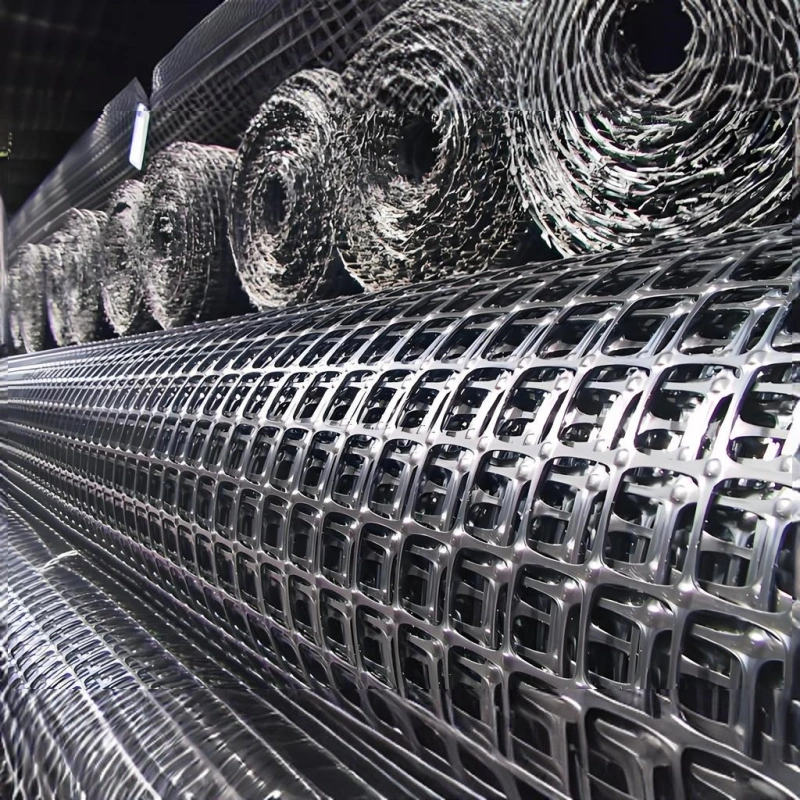

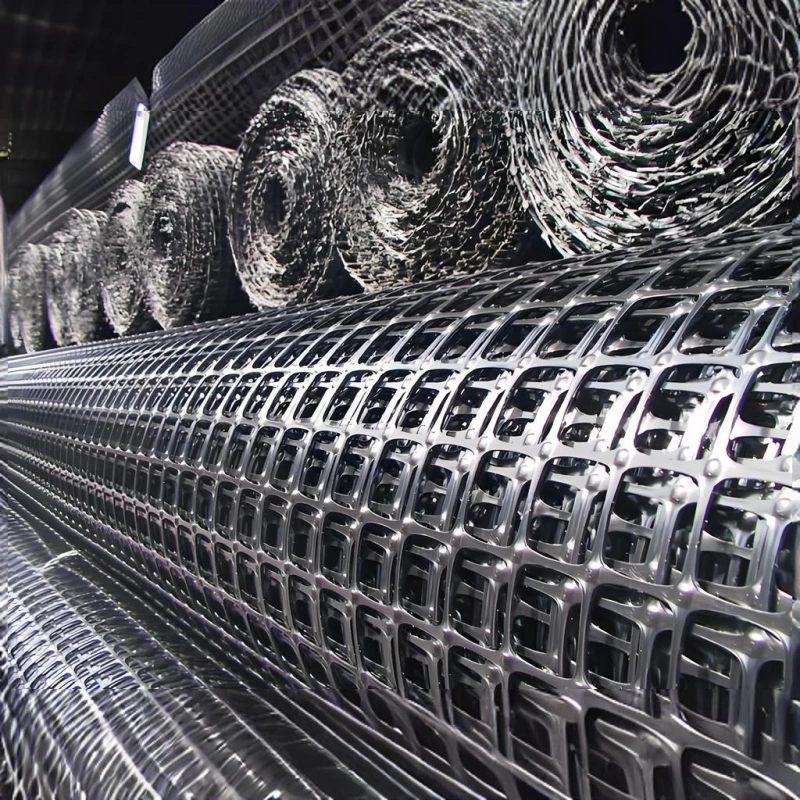

Geogrids are geosynthetic materials designed to reinforce soils and improve their mechanical properties. Typically made from polymers such as polyester, polyethylene, or polypropylene, geogrids have a grid-like structure with openings that allow for interlocking with the surrounding soil. This interlocking mechanism is key to their effectiveness, as it distributes loads more evenly and increases the overall strength of the soil.

Geogrids come in different forms, including uniaxial, biaxial, and triaxial grids, each suited to specific types of reinforcement. Uniaxial geogrids are used primarily for applications requiring high tensile strength in one direction, such as retaining walls. Biaxial and triaxial geogrids, on the other hand, provide reinforcement in multiple directions and are commonly used in slope stabilization.

Technical specifications of geogrids in slope stabilization

Here is a table format for the technical specifications of geogrids in slope stabilization:

| Specification | Details |

|---|---|

| Material Composition | - Polymer Type: Polypropylene (PP), Polyester (PET), High-Density Polyethylene (HDPE) - Coating: PVC or other protective layers |

| Grid Structure | - Uniaxial Geogrids: High tensile strength in one direction - Biaxial Geogrids: Tensile strength in both longitudinal and transverse directions - Triaxial Geogrids: Multi-directional strength |

| Tensile Strength | - Uniaxial Geogrid: 50 to 200 kN/m - Biaxial Geogrid: 20 to 50 kN/m - Triaxial Geogrid: 20 to 60 kN/m |

| Aperture Size | - Opening Dimensions: 20 x 20 mm to 40 x 40 mm - Function: Ensures effective interlocking with soil or aggregate |

| Roll Dimensions | - Width: 1 to 5 meters - Length: 50 to 200 meters - Weight: Varies by material and structure |

| Durability | - UV Resistance: High - Chemical Resistance: Resistant to acids, alkalis, and hydrocarbons - Temperature Resistance: -40°C to +60°C |

| Creep Resistance | - Long-Term Performance: Low creep under sustained loads - Creep Limit: Specified for long-term tensile strength maintenance |

| Installation Specifications | - Overlap Requirements: 30 to 50 cm - Anchoring: Guidelines for securing edges and seams - Backfill Material: Compatible with geogrid for effective interlocking |

| Certifications and Standards | - ISO/ASTM Standards: ISO 10319, ASTM D6637 - Quality Control: Compliance with industry standards |

| Design Considerations | - Slope Angle: Account for angle, soil type, and load conditions - Load Conditions: Consider live loads, dead loads, and dynamic forces |

This table format provides a clear and organized way to present the technical specifications of geogrids used in slope stabilization.

The Role of Geogrids in Slope Stabilization

Slope stabilization involves techniques to prevent soil erosion, landslides, and other forms of slope failure. Geogrids play a critical role in this process by providing additional support and strength to the soil, thereby increasing its resistance to movement and deformation.

Soil Reinforcement: The primary function of geogrids in slope stabilization is to reinforce the soil. By interlocking with the soil particles, geogrids create a composite material that behaves more like a cohesive mass. This reinforcement increases the shear strength of the soil, making it more resistant to sliding or collapsing.

Erosion Control: Geogrids help prevent erosion by stabilizing the soil surface and reducing the likelihood of surface runoff removing soil particles. This is particularly important on slopes where erosion can lead to significant soil loss and weaken the slope's integrity.

Load Distribution: Geogrids help distribute loads more evenly across a slope, reducing the stress on any single point. This is especially beneficial in areas with heavy construction traffic or where retaining structures are used, as it reduces the risk of localized failure.

Slope Angle Optimization: With the use of geogrids, engineers can design steeper slopes than would otherwise be possible. This is particularly useful in space-constrained areas where maximizing land use is essential, such as along highways or in urban developments.

Applications of Geogrids in Slope Stabilization

Geogrids are used in a wide range of applications to stabilize slopes and prevent erosion. Some of the most common uses include:

Retaining Walls: Geogrids are often used in conjunction with retaining walls to provide additional support and prevent soil movement. The geogrid is typically placed behind the wall, extending into the slope, where it reinforces the soil and anchors it to the retaining structure.

Road Embankments: In road construction, geogrids are used to stabilize embankments and prevent them from shifting or settling under the weight of traffic. This ensures the long-term stability of the road and reduces maintenance costs.

Landslide Mitigation: In areas prone to landslides, geogrids are used to reinforce slopes and prevent soil movement. This application is especially important in regions with steep terrain or where heavy rainfall is common, as it helps protect infrastructure and communities from landslide damage.

Slope Landscaping: Geogrids are also used in landscaping projects to stabilize slopes and prevent erosion. This is particularly useful for creating terraces, gardens, and other landscape features on sloped terrain.

Benefits of Using Geogrids

The use of geogrids in slope stabilization offers several key benefits:

Cost-Effectiveness: Geogrids provide a cost-effective solution for slope stabilization, reducing the need for expensive earthworks or retaining structures. Their ability to reinforce soil and prevent erosion also reduces long-term maintenance costs.

Versatility: Geogrids can be used in a variety of soil types and slope conditions, making them a versatile option for many different projects. Their flexibility in design and installation allows for customized solutions to meet specific geotechnical challenges.

Environmental Sustainability: Geogrids are an environmentally friendly option for slope stabilization, as they reduce the need for large-scale excavation and earth-moving activities. By preventing erosion, they also help protect natural landscapes and reduce the impact of construction on the environment.

Durability: Geogrids are highly durable and resistant to environmental factors such as UV exposure, chemicals, and biological degradation. This ensures that they provide long-lasting reinforcement for slope stabilization projects, even in harsh conditions.

Manufacturing standards for geogrids used in slope stabilization

When it comes to the manufacturing standards for geogrids used in slope stabilization, several key standards and guidelines are followed to ensure quality, performance, and safety. Below are the primary standards associated with the manufacturing and testing of geogrids:

1. ISO Standards

ISO 10319: Geosynthetics - Wide-width tensile test

This standard specifies the method for determining the tensile properties of geosynthetics, including geogrids. The test measures the strength and strain characteristics of the material when subjected to a uniaxial tensile load.ISO 13426: Geosynthetics - Strength of internal structural junctions

Part 1: Geocells

Part 2: Geogrids These parts outline the methods for assessing the strength of the internal structural junctions (the points where the ribs intersect) of geogrids, which are critical to their overall performance in slope stabilization.

ISO 9001: Quality Management SystemsWhile not specific to geogrids, ISO 9001 certification ensures that the manufacturer follows a rigorous quality management process, ensuring consistent product quality and adherence to specifications.

2. ASTM Standards (American Society for Testing and Materials)

ASTM D6637: Standard Test Method for Determining Tensile Properties of Geogrids by the Single or Multi-Rib Tensile Method

This standard is commonly used in the U.S. and other regions to determine the tensile strength and elongation characteristics of geogrids. The test can be conducted on a single rib or multiple ribs to assess their performance under tension.ASTM D4759: Standard Practice for Determining the Specification Conformance of Geosynthetics

This practice provides procedures for verifying that geosynthetics, including geogrids, meet the specified requirements as stated in purchase agreements or specifications.ASTM D5262: Standard Test Method for Evaluating the Unconfined Tension Creep and Creep Rupture Behavior of Geosynthetics

This test method is used to evaluate the long-term creep behavior of geogrids, which is important for assessing their performance over time in slope stabilization applications.ASTM D5321: Standard Test Method for Determining the Shear Strength of Soil-Geosynthetic and Geosynthetic-Geosynthetic Interfaces by Direct Shear Method

This standard assesses the interaction between the geogrid and the soil or other geosynthetics, determining the shear strength at the interface, which is critical for slope stabilization.

3. EN Standards (European Norms)

EN 13249: Geotextiles and Geotextile-related Products - Characteristics required for use in the construction of roads and other trafficked areas

This European standard specifies the essential characteristics of geotextiles and related products, including geogrids, for their use in road construction and other load-bearing applications, which often include slope stabilization.EN 10223-3: Steel Wire and Wire Products for Fences - Part 3: Hexagonal Steel Wire Mesh Products

Although this standard primarily covers wire mesh, it's relevant to some types of geogrid structures that may incorporate steel reinforcement.

4. Geosynthetic Research Institute (GRI) Standards

GRI-GG1: Standard Specification for Geogrids

This specification outlines the requirements for manufacturing geogrids, including properties such as tensile strength, junction strength, and aperture stability. It's widely used in North America.GRI-GG2: Standard Test Method for Determining the Flexural Rigidity of Geogrids

This test measures the stiffness of geogrids, which is important for understanding how they will perform when subjected to flexural loads in slope stabilization.

5. Additional Manufacturing Standards

Quality Control (QC) Procedures: Manufacturers often follow internal quality control procedures that are based on the above standards and include regular testing of raw materials, monitoring of production processes, and batch testing of finished products.

Environmental Standards: Depending on the region, manufacturing processes may need to comply with environmental standards to reduce emissions, waste, and energy consumption during the production of geogrids.

These standards ensure that geogrids are manufactured to meet the required performance criteria for slope stabilization, providing confidence in their long-term durability and effectiveness in preventing soil erosion and slope failure.

Conclusion

Geogrids have become an essential tool in modern geotechnical engineering, providing a reliable and effective solution for slope stabilization. Their ability to reinforce soil, prevent erosion, and enhance slope stability makes them a valuable asset in a wide range of construction and landscaping projects. As the demand for sustainable and cost-effective engineering solutions continues to grow, the use of geogrids is likely to expand, helping to ensure the safety and longevity of infrastructure in challenging terrains.

About Haoyang Environmental

Haoyang Environmental is a Geogrids factory from China, specializing in the production of high-quality geogrids used for slope stabilization, soil reinforcement, and erosion control. Their products are designed to meet international standards, ensuring durability, strength, and reliability in various geotechnical applications. With a focus on innovation and environmental sustainability, Haoyang Environmental provides customized geogrid solutions tailored to the specific needs of construction and infrastructure projects worldwide.

![]() Geogrid_for_Slope_Stabilization_Specifications.pdf

Geogrid_for_Slope_Stabilization_Specifications.pdf

503.webp)

759.webp)