Geotextile Fabric Woven Filter Fabric Filament in Road Construction

Haoyang Environmental Co., Ltd. is a leading provider of high-quality geosynthetic materials and solutions for various construction and environmental applications. With over 15 years of expertise in geosynthetic research, development, and manufacturing, Haoyang has become a trusted name in providing innovative and reliable materials for road construction and other infrastructure projects. Our geotextile fabric woven filter fabric filament is designed to enhance the performance of road construction projects by providing superior filtration, separation, and reinforcement capabilities.

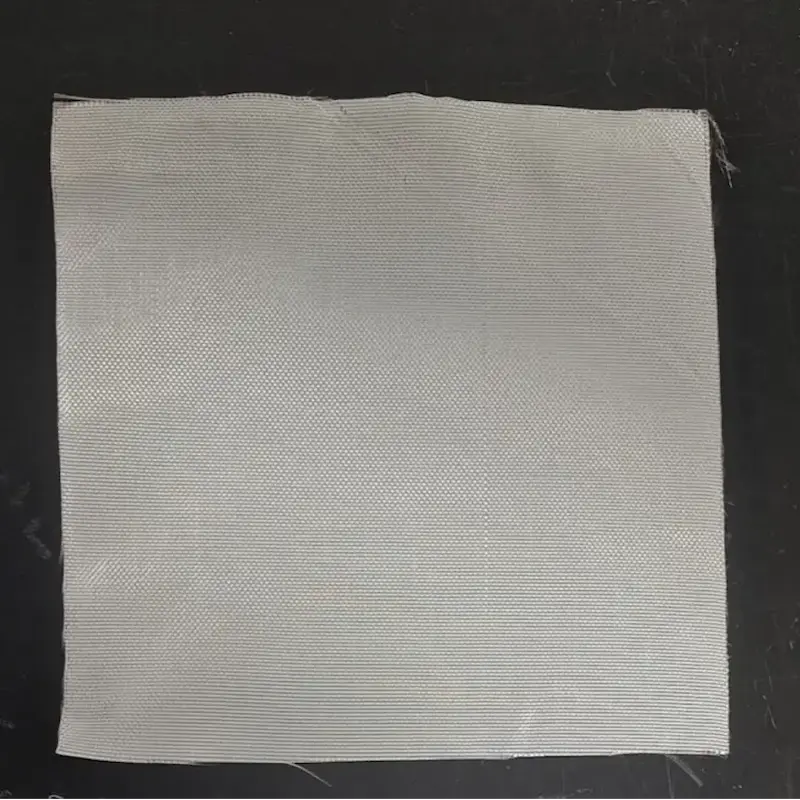

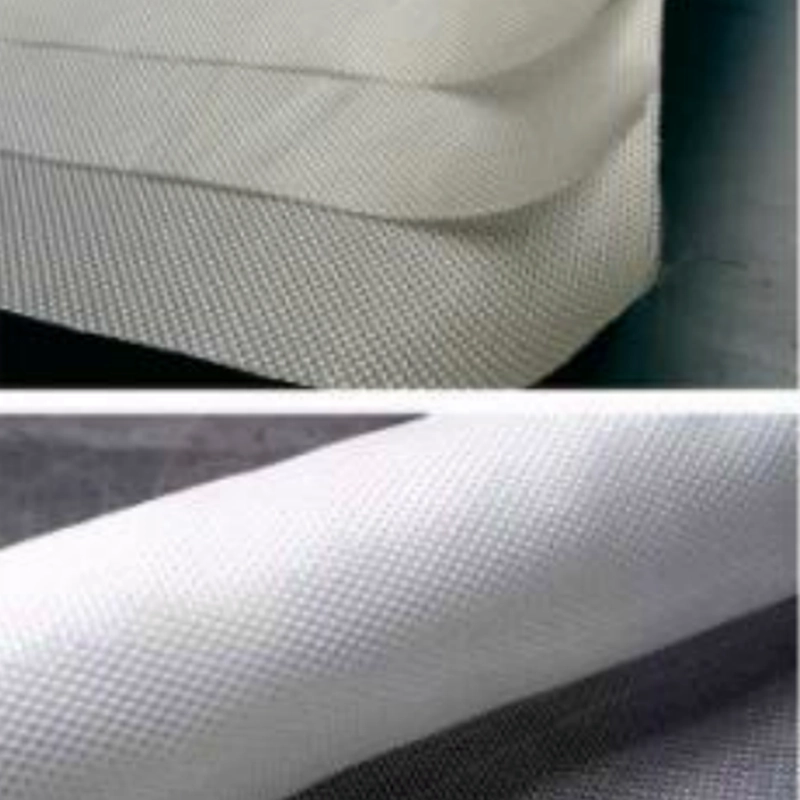

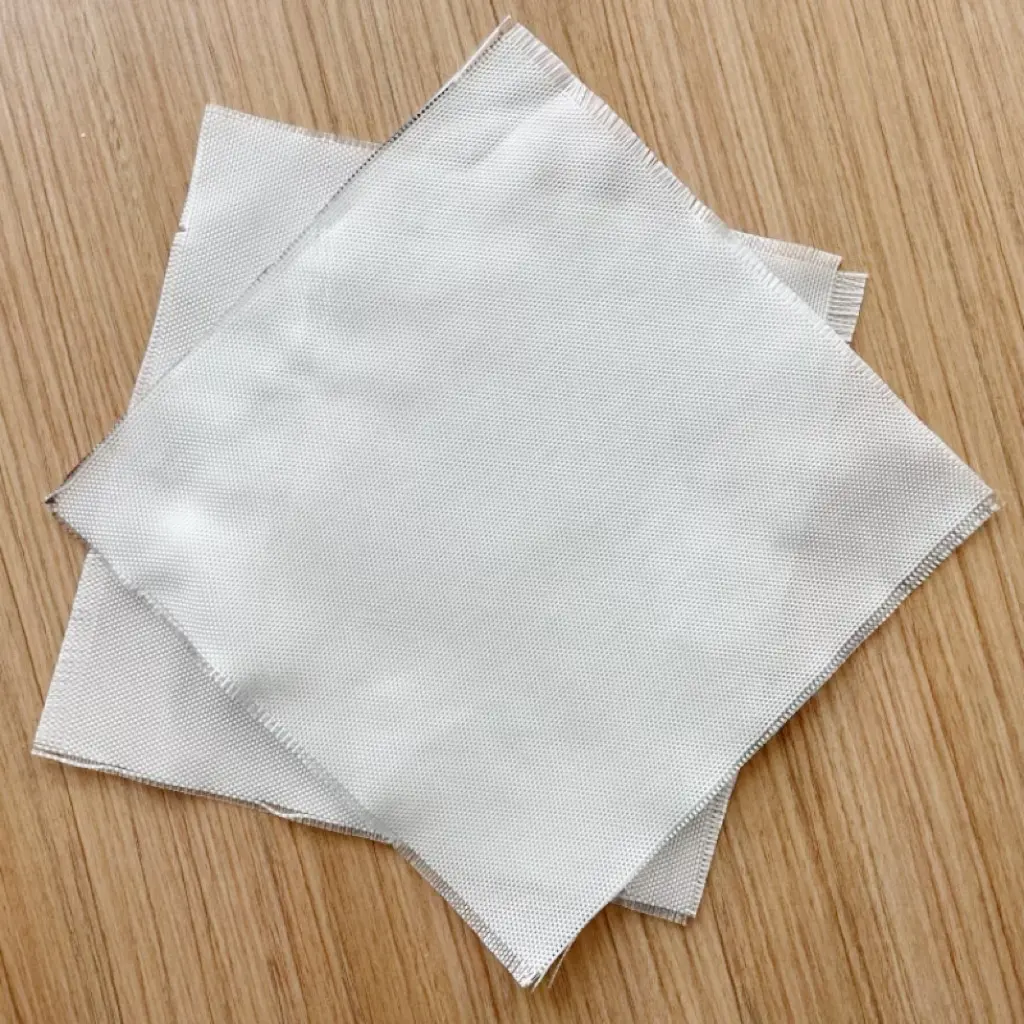

Geotextile Fabric Woven Filament

Geotextile woven filament fabric is a synthetic fabric made from high-strength, low-elongation filament fibers such as polypropylene and polyester through a weaving process. Typically, it is woven from two sets of filaments. Classified by its intended use, geotextile varieties include single-layer woven geotextile (also known as silt filter fabric), double-layer geotextile (also known as geotextile mat), and woven geomembrane. It is suitable for applications such as slope protection and bank reinforcement in rivers, seas, and coastal areas, as well as water collection areas, revetment protection in harbors, flood prevention and emergency response, reinforcement of embankments and dykes, foundation stabilization of soft soil, construction of cofferdams, and various erosion control projects.

Specifications

| Item | Specification | ||||||||||

| Unit Area Mass(g/m²) | 140 | 200 | 260 | 320 | 390 | 460 | 530 | 600 | 680 | 760 | 950 |

| Nominal Breaking Strength(kN/m) | 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 |

| Longitudinal Tensile Strength(kN/m)≥ | 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 |

| Transverse Tensile Strength(kN/m)≥ | As stipulated in the agreement, in the absence of specific requirements, it shall be processed according to the nominal breaking strength in the warp direction multiplied by 0.7. | ||||||||||

| Standard Strength Corresponding Elongation≤ | Warp 35, Weft 30 | ||||||||||

| CBR(kN)≥ | 2 | 4 | 6 | 8 | 10.5 | 13 | 15.5 | 18 | 20.5 | 23 | 28 |

| Equivalent Pore Size O s ( O s ) / mm | 0.05~0.50 | ||||||||||

| Vertical Permeability Coefficient(cm/s) | K×(10-²~10~5),K=1.0~9.9 | ||||||||||

| Biaxial Tear Strength(kN)≥ | 0.4 | 0.7 | 1 | 1.2 | 1.4 | 1.6 | 1.8 | 1.9 | 2.1 | 2.3 | 2.7 |

Product performance

1, High tensile, tear, puncture resistance, and other mechanical strengths make it more than twice as strong as geotextiles of equivalent weight made from short fibers. Specifically, it excels in resisting puncture and top bursting forces, with a strength reaching 2200 Newtons or more. In applications such as stone revetment, it effectively prevents irregular stones from impacting the fabric surface.

2, Relying on the mutual compression of warp and weft yarns to maintain structural stability, high-strength woven geotextile is particularly suitable for reinforcement, strengthening, and isolation applications.

3, Excellent chemical resistance; corrosion resistance.

Main Applications

Used for reinforcement in backfilling of retaining walls or as panels for anchoring retaining walls. Also employed in constructing wrapped retaining walls or bridge abutments.

Reinforcing flexible road surfaces, repairing cracks in roads, preventing the reflection of cracks in the pavement, increasing the stability of crushed stone slopes and reinforced soil, preventing soil erosion and frost damage to the soil in low temperatures. It can be used as an isolation layer between road chips and the subgrade, or as an isolation layer between the subgrade and soft foundation. It also can serve as isolation layers between highways, airports, railway ballast, artificial stone heaps, and the foundation. And they are widely used in projects such as highways (including temporary roads), railways, embankments, earth-rock dams, airports, and sports fields to strengthen weak foundations.

Funtions in Road Construction

Geotextile woven filament fabric plays a crucial role in road construction engineering, primarily contributing to reinforcement, protection, drainage and filatration.

1, Reinforcement: With its high strength and low elongation characteristics, long filament woven geotextile is utilized to reinforce weak foundations in road projects. By laying the geotextile in the subgrade layer, it effectively disperses loads, enhances the bearing capacity of the foundation, and improves overall deformation resistance. This is particularly important for road, railway, and airport projects, especially in regions subjected to heavy traffic loads.

2, Protection: Long filament woven geotextile is employed for protective purposes in road engineering, especially in preventing soil erosion and resisting external environmental threats. It serves as an effective barrier, preventing soil erosion and safeguarding embankments and slopes from rainwater erosion. Additionally, it prevents particles in the foundation from being washed away, contributing to the integrity of the road structure.

3, Drainage: Long filament woven geotextile often possesses good permeability, making it a valuable component of drainage systems. In road projects, it can be used as a drainage layer to help eliminate accumulated water beneath the road surface, prevent water retention, and reduce the saturation of the foundation. This positively impacts the stability, durability, and minimizes muddy conditions on the road.

4, Filtration: Beyond its primary roles, long filament woven geotextile serves as an effective filtration medium. It prevents the migration of fine particles, allowing water to pass through while retaining soil particles. This filtration function is instrumental in maintaining the long-term effectiveness of the geotextile and ensuring the proper functioning of the overall road system.

If you are looking for or have any questions of geotextile woven filament fabric, please feel free to contact us, and then let me show you our factory.

Workshop

As you can see, this is our filament geoeotextile woven production line, Polyester, polypropylene, and nylon high-strength filament fibers are used as raw materials, and they are processed through twisting and woven using a negative rapier loom to produce long filament woven geotextile. The geotextile can achieve a maximum weight of 800g/m², a strength of 250KN, and a maximum width of 6.3 meters. The production capacity is 3000 tons per year.

655173.webp)

Besides filament geoeotextile woven products, we can also supply smooth/textured geotextile membrane, composite geotextile membrane, polyester spunbond filament geotextile, polyester/polypropylene short fiber geotextile, three-dimensional composite drainage net, GCL, single/double-directional geogrid, and other geosynthetic materials with waterproof, anti-seepage, reinforcement, isolation, and filtration functions.

Quality and R&D

As the market demands for geotechnical materials continue to rise, our company has taken further steps to enhance our laboratory facilities. From the arrival of raw materials to the final product delivery, we have implemented a stringent testing process control. In order to meet testing requirements, our company has not only improved the instruments for the physical property testing of products but has also acquired equipment for aging index testing. This includes instruments such as the geotextile membrane ultraviolet aging test chamber, geotextile membrane oxidation induction time tester, and other testing equipment. These additions provide robust assurance for the quality of our products.

822892.webp)

Our factory has successfully obtained ISO quality certification and environmental certification. This not only recognizes our commitment to outstanding quality but also signifies our dedication to environmental sustainability. The ISO certification ensures that we have an efficient quality management system, striving to deliver consistently excellent products and services, creating an exceptional experience for our customers. Simultaneously, the environmental certification represents our commitment to environmental awareness throughout the production process. We aim for sustainability by optimizing processes and reducing environmental impact. These certifications not only enhance our competitiveness in the international market but also strengthen the trust relationship with our customers. They can confidently choose us, knowing they will receive high-quality, environmentally friendly products.

788792.webp)

Company Advantages

ISO Certifications: Haoyang holds ISO 9001, ISO 14001, and OHSAS 18001 certifications, ensuring we adhere to international standards for quality, environmental management, and occupational safety.

Innovative Technology: With over three invention patents and 32 utility model patents, Haoyang is at the forefront of technological innovation in geosynthetic materials and environmental engineering solutions.

Proven Track Record: Our products have been widely adopted in large-scale infrastructure projects worldwide, including road construction, water management, and environmental protection projects.

Technical Expertise: Our team of experts and engineers is dedicated to providing the best solutions for your project needs, offering comprehensive support from design to execution.

For more information or to request a quote, please contact Haoyang Environmental Co., Ltd. Our team is ready to assist you with the ideal geotextile fabric solution for your road construction and environmental protection needs.

FAQ

1. What is the purpose of using geotextile fabric in road construction?

Geotextile fabric is used to provide reinforcement, separation, and filtration in road construction. It enhances the structural integrity of the road, prevents mixing of different soil layers, and aids in drainage.

2. How does woven filter fabric contribute to erosion control in road construction?

Woven filter fabric helps control erosion by preventing soil particles from being washed away. It acts as a barrier, allowing water to pass through while retaining the soil, thereby stabilizing slopes and embankments.

3. What are the key benefits of using filament geotextile in road projects?

Filament geotextile provides high tensile strength, durability, and resistance to deformation. It effectively reinforces soft soil, improves load-bearing capacity, and prolongs the lifespan of road structures.

4. How does geotextile fabric assist in preventing reflective cracking in roads?

Geotextile fabric acts as a stress-absorbing interlayer, distributing loads and preventing the propagation of cracks from the existing pavement. This helps in reducing reflective cracking and extending the life of the road.

5. Can geotextile fabric be used in different climate conditions for road construction?

Yes, geotextile fabric is designed to withstand various climate conditions. It resists deterioration due to exposure to UV rays, moisture, and temperature variations, making it suitable for use in diverse road construction environments.

254.webp)

503.webp)

759.webp)