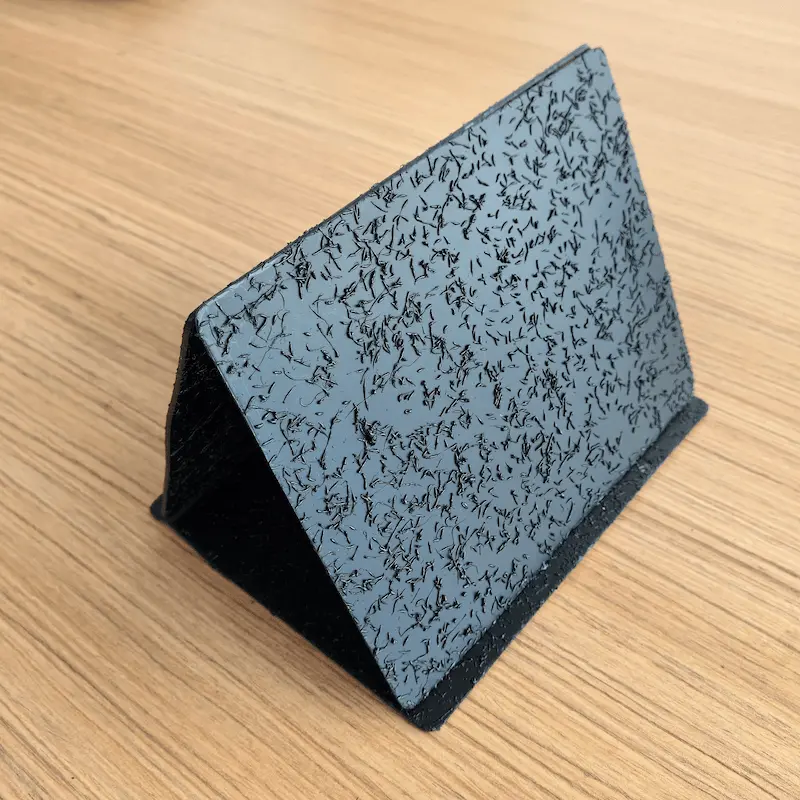

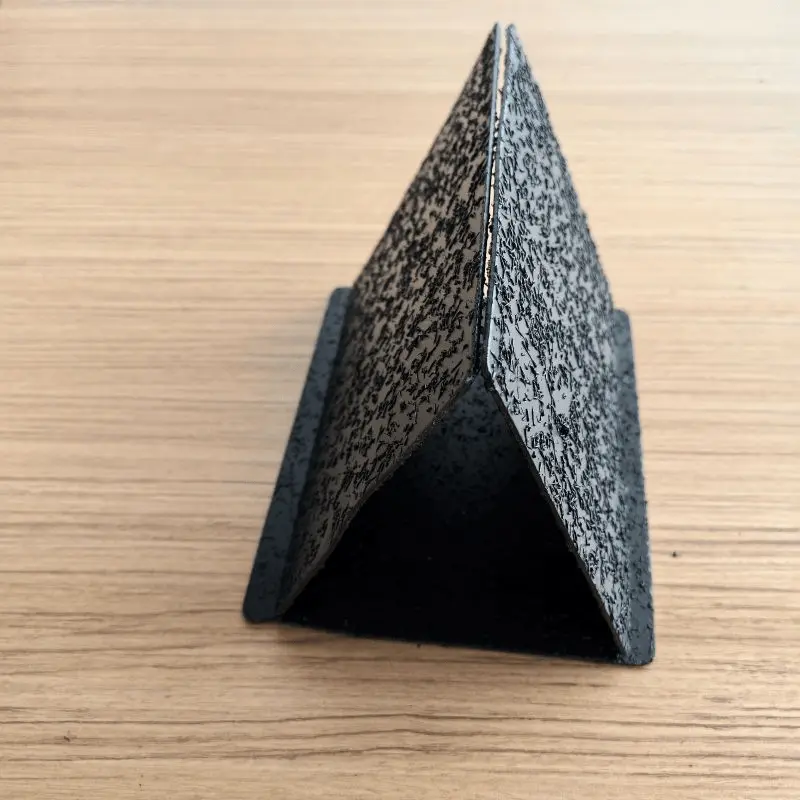

Textured geomembranes are specialized geosynthetic materials designed to provide enhanced friction and stability in various engineering applications. These geomembranes feature a textured surface, which improves their adhesion to soils, rocks, and other materials, making them ideal for use in waterproofing, environmental protection, water conservancy, and high-speed rail projects. In this article, we will explore the key features, specifications, and pricing of 1-3mm textured geomembranes for use in these critical infrastructure projects in China.

1-3mm Waterproof Textured Geomembrane

Haoyang Environmental Co., Ltd. is a trailblazer in cutting-edge environmental solutions since 2008. With a steadfast commitment to innovation and excellence, we specialize in revolutionizing geosynthetic materials to safeguard our planet's ecosystems.Our 1-3mm waterproof textured geomembrane. Crafted with precision and purpose, this state-of-the-art membrane sets a new standard in environmental protection and engineering efficiency.

Textured Geomembrane - Protect Your Project with Unparalleled Quality!

In the vast world of engineering, every detail counts. Waterproof textured geomembrane, as our company's star product, has become the first choice for countless engineers due to its unique quality and performance.

Waterproof textured geomembrane has a variety of advantages, here are its main advantages:

Excellent anti-seepage performance: The rough surface of waterproof textured geomembrane has a large friction coefficient, which can effectively prevent soil loss and sliding, enhancing the stability of the slope. At the same time, its anti-seepage coefficient is much lower than that of ordinary waterproof materials, with excellent anti-seepage effect.

Chemical stability: Waterproof textured geomembrane has excellent chemical stability, can resist the corrosion of most strong acids and alkalis, so it is widely used in environments such as sewage treatment, chemical reaction tanks, and garbage landfills.

Resistance to aging: Waterproof textured geomembrane has good resistance to aging, UV resistance, and decomposition resistance, with a service life of up to 50-70 years, providing good protection for environmental anti-seepage.

Resistance to plant root penetration: Waterproof textured geomembrane can resist the penetration of most plant roots, effectively preventing plant roots from damaging the geomembrane and extending the service life of the project.

High strength and environmental temperature resistance: Waterproof textured geomembrane has high strength and environmental temperature resistance, able to maintain stability in extreme environments and provide reliable protective effect.

Good construction performance: Waterproof textured geomembrane has good construction performance, easy to lay and install, able to greatly improve the efficiency of project construction.

In general, rough-surfaced geomembrane is a high-quality geotechnical material with excellent performance, wide application, and ease of construction, making it an ideal choice for your engineering construction.

Textured Geomembrane Specification

Number | Ltem | Value | ||||||

Thickness mm | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 | |

1 | Density g/cm3 | ≥0.940 | ||||||

2 | Rough height mm | ≥0.25 | ||||||

3 | Tensile yield strength(MD and CD) N/mm | ≥11 | ≥15 | ≥18 | ≥22 | ≥29 | ≥37 | ≥44 |

4 | Tensile break strength(MD and CD) N/mm | ≥8 | ≥10 | ≥13 | ≥16 | ≥21 | ≥26 | ≥32 |

5 | Elongation at yield(MD and CD) N/mm | ≥12 | ||||||

6 | Elongation at break(MD and CD) % | ≥100 | ||||||

7 | Tear resistance(MD and CD) % | ≥93 | ≥125 | ≥160 | ≥190 | ≥250 | ≥315 | ≥375 |

8 | Puncture strength N | ≥200 | ≥270 | ≥335 | ≥400 | ≥535 | ≥670 | ≥800 |

9 | Tensile stress cracking(incision constant load stretching) h | ≥300 | ||||||

10 | Carbon blank content % | 2.0~3.0 | ||||||

11 | Carbon black dispersion | There are no more than 1 in the 10 data,no 4 or 5 | ||||||

12 | Oxdation induction time min min | Normal pressure oxidation induction time≥100 | ||||||

High pressure oxidation induction time≥400 | ||||||||

13 | Oven aging at 85 ℃,(StandareOIT(min.ave.) -oretained after 9Cdays ) % | ≥55 | ||||||

14 | UV Rresistance (High PressureOIT(min.ave)-%retained after 1600hrs) % | ≥50 | ||||||

Specifications of 1-3mm Textured Geomembrane

The specifications of textured geomembranes can vary depending on the project requirements and environmental conditions. Below is a general specifications table for 1-3mm textured geomembranes:

| Specification | Details |

|---|---|

| Material | HDPE or LLDPE |

| Thickness | 1.0 mm, 1.5 mm, 2.0 mm, 2.5 mm, 3.0 mm |

| Surface Texture | Single-sided or double-sided textured |

| Width | 5.8 m, 7.0 m, 8.0 m (custom widths available) |

| Length | 50 m to 200 m (custom lengths available) |

| Density | ≥ 0.94 g/cm³ |

| Tensile Strength | ≥ 25 MPa |

| Elongation at Break | ≥ 700% |

| Puncture Resistance | ≥ 550 N |

| Tear Resistance | ≥ 125 N |

| Environmental Stress Crack Resistance | ≥ 300 hr |

| Carbon Black Content | 2% - 3% (for UV resistance) |

| Water Vapor Transmission | ≤ 1.0 × 10⁻¹³ g.cm/cm².s.Pa |

| Temperature Range | -40°C to 85°C |

| UV Resistance | Excellent (≥ 90% strength retention after 500 hours exposure) |

| Chemical Resistance | Resistant to acids, alkalis, and hydrocarbons |

| Standard Compliance | ASTM D5199, ASTM D6392, ISO 9001, GRI-GM13 |

Pricing of 1-3mm Textured Geomembrane

The pricing of textured geomembranes depends on factors such as thickness, width, length, and additional customization options. Below is a general price table based on common specifications:

| Thickness | Width | Length | Price Range (USD/m²) |

|---|---|---|---|

| 1.0 mm | 5.8 m | 100 m | $1.80 - $2.20 |

| 1.5 mm | 6.0 m | 100 m | $2.20 - $2.70 |

| 2.0 mm | 7.0 m | 100 m | $2.70 - $3.20 |

| 2.5 mm | 7.5 m | 100 m | $3.20 - $3.80 |

| 3.0 mm | 8.0 m | 50 m | $3.80 - $4.50 |

Textured Geomembrane Installation Steps

The construction of Haoyang Environmental Protection Co., Ltd. mainly includes the following steps:

Preparation stage: Before construction, the site needs to be cleaned up to ensure a smooth and level ground without any significant irregularities. Meanwhile, for the soil that comes into contact with the membrane, a protective layer of sand or clay with a small particle size should be laid.

Laying stage: Firstly, rough surface layer is laid, usually using gravel, broken bricks, gravel, etc. The thickness of the rough surface layer is generally 10-15cm, and it should be laid evenly to ensure no significant height difference. Next, the geomembrane is laid on the rough surface layer. The choice of geomembrane should be based on the needs of the project. Common geomembranes include HDPE geomembrane and LDPE geomembrane. The geomembrane should be laid smoothly, without obvious wrinkles and damage.

Fixation stage: Use long wooden piles or fixers to secure the edges of the geomembrane to the ground, ensuring that the geomembrane will not be blown up by the wind or washed away by water.

Reversing the seams stage: reversing the seams at the geomembrane seams to ensure that there is no leakage at the seams. The reversing length at the seams is generally 30-40cm.

Covering the rough surface layer stage: A rough surface layer with a thickness of about 10cm is laid on the geomembrane to protect it. The thickness of the rough surface layer can be increased or decreased appropriately according to the specific situation.

Review and acceptance stage: Review and accept the rough-surfaced geomembrane after construction to ensure that the construction quality meets the requirements.

1-3mm textured geomembranes are essential materials for a wide range of engineering projects in China, providing effective waterproofing and environmental protection. With their enhanced friction properties, chemical resistance, and durability, they are suitable for use in water conservancy, high-speed rail, and environmental protection projects. Understanding the specifications and pricing of these geomembranes is crucial for selecting the right product for your project needs. For more detailed pricing and customized specifications, it is recommended to consult with reputable suppliers or manufacturers.

Why Choose Us

We know that every project has its own unique requirements. Therefore, we provide customized services and can produce rough-surfaced geomembranes of corresponding specifications based on your specific needs. No matter what the size of your project, we can provide you with the most suitable solution.

In addition to product performance, we also focus on service experience. From environmental consulting, engineering design to equipment manufacturing and operation maintenance, our professional team will provide you with comprehensive support and services to ensure the smooth progress of the project.

Partner with Haoyang

Waterproof textured geomembrane uses advanced production processes to ensure its rough surface structure can provide good friction performance and prevent soil loss and sliding in engineering projects. At the same time, it also has excellent weather resistance and chemical resistance, able to maintain stability in various adverse environments and ensure long-term safety of the project.

Haoyang Environmental Protection Co., Ltd. - the trusted choice for rough-surfaced geomembranes! We protect your every project with our unparalleled quality and commitment to excellence. Choose us for reliable and effective solutions that ensure the safety and longevity of your construction projects.

Partner with Haoyang Environmental Co., Ltd., and embark on a journey towards a cleaner, greener future. Together, let's pave the way for sustainable progress with our innovative 1-3mm waterproof textured geomembrane.