In the realm of impermeable engineering, geosynthetic materials play a pivotal role in ensuring the integrity, durability, and environmental sustainability of diverse projects. Here

we will explore the significance of geotextile fabric and geotextile membrane in impermeable engineering applications, shedding light on their unique properties and versatile contributions.

Design and Construction of Geotextile membrane for Seepage Control

The successful design and construction of a geomembrane for seepage control require a comprehensive understanding of the site conditions, careful material selection, and adherence to engineering best practices throughout the installation process.

Factors need to take into consideration

The design and construction of geomembrane for seepage control should take into consideration the following factors:

1, Project Nature:

Determine whether the project is temporary or permanent, and whether the primary purpose is main seepage control or secondary seepage control.

2, Long-Term Working Conditions:

Assess whether the geomembrane will be buried in the soil or exposed to the external environment.Consider the impact of extreme environmental conditions, such as high and low temperatures, sunlight exposure, hurricanes, and corrosive surroundings.Evaluate additional loads beyond construction stresses, such as significant tensile forces on slopes or uneven settlement.

3, Construction Conditions:

Take into account local weather conditions, including temperature, precipitation, wind speed, and the nature of fill materials.

These factors play a crucial role in determining the appropriate design specifications and construction methods for the geomembrane. They encompass considerations related to the project's duration, environmental exposure, and the potential impact of various loads and construction conditions, ensuring the effectiveness and longevity of the seepage control system.

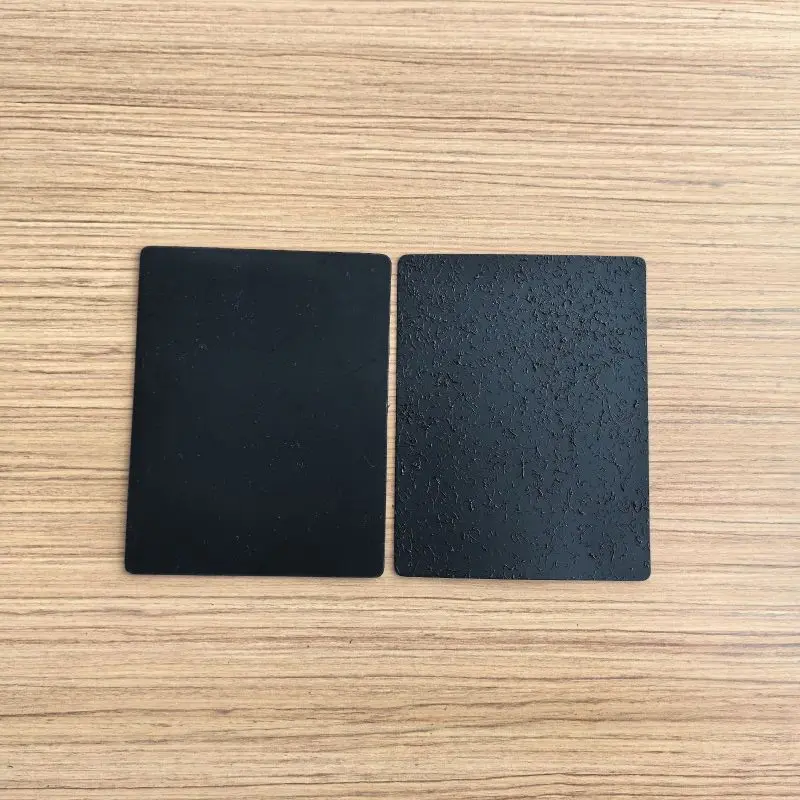

Selection of geotextile membrane

1, For projects in contact with water, it is advisable to use polyethylene geomembrane.

2, When in contact with liquids rich in acidic, alkaline, salt, and heavy metal elements, geotextile membrane material should be selected based on the principle of chemical resistance.

3, In waste disposal sites with uncertain chemical compositions, high-density polyethylene (HDPE) membrane is preferred.

4, The thickness of the geo textile membrane should not be less than 0.5mm. For critical or strictly regulated projects, such as waste disposal sites, the geomembrane should be thickened.

Construction procedures

1, Preparation (Site Clearing) Work:

Clear the site, excavate anchor trenches, and establish drainage and ventilation systems.

Geomembrane Selection:

2, Choose wide-width membranes and splice them to the required dimensions in the factory, then transport them to the construction site on steel shafts.

Membrane Installation:

3, Installation is recommended during dry and cool weather. Lay the membrane loosely and without wrinkles, ensuring proper allowance for relaxation in membrane dimensions. Personnel should wear soft-soled shoes.

4, Seaming:

Utilize hot wedge welding and adhesive methods. Hot wedge welding is used for PE membranes, while PVC membranes can be seamed using hot wedge welding or adhesive methods. Prior to membrane installation, conduct a trial weld to determine suitable welding temperature and speed. Adhesive methods are often employed for local repairs, and the stability of the adhesive should meet design requirements.

5, Backfilling After Successful Seaming:

Backfill in layers as soon as seaming is completed. Fill material and compaction must not damage the geomembrane.

Water Conservancy Engineering Seepage Control

113067.webp)

Seepage control design for earth and rockfill dams

1, The selection of geosynthetic membrane type, material, and thickness should be determined based on factors such as hydraulic head, fill material, subgrade conditions, and the location of installation.

2, When geosynthetic membranes are used in the construction of Grade 1, Grade 2 structures, and high dams, they should undergo specialized analysis. The membrane thickness should be selected according to the importance and classification of the dam. For Grade 1 and Grade 2 structures, the thickness of the geosynthetic membrane should not be less than 0.5mm, and for structures with high hydraulic heads or of significant importance, appropriate thickening is recommended. For Grade 3 and below projects, the thickness should not be less than 0.3mm.

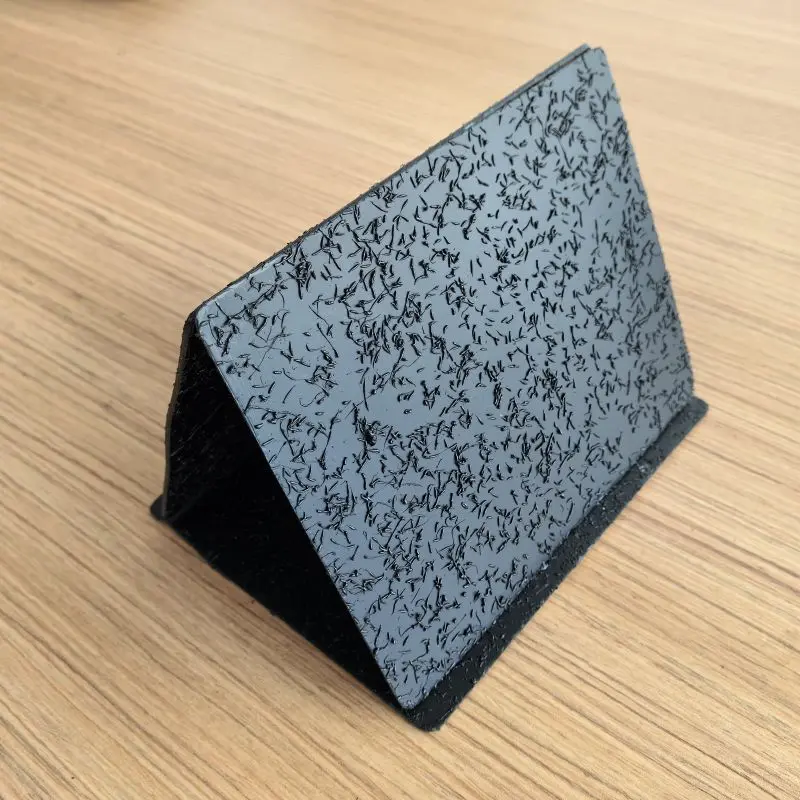

3, Seepage control structures should ensure stability. Measures such as surface roughening of the membrane, laying it in a stepped, zigzag, or pleated pattern can be employed to enhance stability.

4, When using seepage control materials for structures like sloping walls and core walls, they should be closely connected to seepage control facilities on the dam foundation and slope, forming a complete sealing system.

5, For large underwater installations, such as reservoirs and dam bases, drainage and venting measures should be implemented beneath the seepage control membrane to address water accumulation.

Seepage control design for water conveyance channels

1, The type, material, and thickness of seepage control materials should be determined based on local climate, geological conditions, and the scale of the project.

2, The installation height of seepage control materials on channel slopes should reach above the highest water level, and there should be secure fastening of the seepage control materials.

3, Seepage control structures in cold regions should adopt anti-freezing measures.

4, When using geomembranes as seepage control layers to intercept underground or surface water flow, the following requirements should be met:

1), The thickness of the geomembrane for vertical seepage control and interception of subsurface flow should not be less than 0.3mm. For significant projects, the membrane thickness should not be less than 0.5mm, and the placement depth should be within 15m.

2), When used as a vertical seepage control wall, the particle content with a diameter greater than 50mm in the permeable layer should not exceed 10%. The selection of trenching machines and wall-fixing methods for laying geomembranes in the trench should be based on the specific conditions of the foundation soil.

3), After trenching and membrane placement, timely backfilling should be carried out, and measures should be taken to prevent bottom-end seepage. The upper end of the geomembrane should be connected to the surface seepage control structure.

4), When using geomembranes for horizontal seepage control (cover) in reservoirs, the membrane thickness should not be less than 0.5mm, and a composite membrane with non-woven geotextile fabric should be used. The extension length of the membrane towards the upstream side of the reservoir dam should be calculated according to relevant hydraulic engineering standards. The reservoir bottom should be leveled, sharp debris should be removed, and the drainage, venting facilities beneath the membrane, and the sealed connection between the membrane and the shore should comply with design requirements.

Transportation Engineering Seepage Control

1, As a seepage control and isolation layer for roadbeds, geosynthetic membranes or composite geomembranes are used to prevent the roadbed from heaving and mud emergence, control saline-alkali reactions, and resist groundwater infiltration into expansive soil and collapsible loess roadbeds. These materials should be placed at appropriate positions for seepage control and isolation within the roadbed, simultaneously intercepting lateral inflow. Closed and drainage systems should also be installed.

2, In the seepage control design of underground railways and traffic tunnels, composite geomembranes can be used for waterproofing in cavernous spaces, while caverns with significant drainage volumes may utilize suitable drainage-resistant composite materials. For caverns and tunnels in rock formations, after excavation, the walls should be sprayed to form a smooth surface. Subsequently, composite geomembranes (with thicker non-woven fabrics) should be installed. When using geomembranes for seepage control in traffic tunnels, the geotextile side of the membrane should be tightly attached and secured to the tunnel walls.

Building Project Waterproofing

When synthetic geotechnical materials are used in roof waterproofing projects, they should meet the following specifications:

1, Composite geotechnical membranes should withstand water pressure of 0.3MPa for a minimum of 30 minutes without leakage, and their heat stability should comply with design requirements.

2, Composite geotechnical membranes can be used independently as a waterproof layer or combined with other waterproof materials to create a multi-layer waterproofing system. Surface protection measures should be taken during installation.

3, Seams and adhesives for composite geotechnical membranes should be compatible with the selected membrane.

Environmental Protection Engineering Waterproofing

The double lining anti-seepage system for landfills should include a leachate collection layer and a leachate detection layer. Leakage testing should be conducted after the construction is completed. The leachate collection layer is used during the operation of the landfill to control the depth of leachate on the anti-seepage HDPE geomembrane, which should not exceed 300mm. When the leachate detection layer detects leakage in the anti-seepage layer, prompt measures can be taken.

After the landfill is finally filled, it should be promptly sealed to prevent prolonged infiltration of precipitation. The sealing system, from bottom to top, should include a gas drainage layer, an anti-seepage layer, a rainwater drainage layer, a final cover layer, and a ground vegetation layer.

FAQ

1: What is the purpose of using geotextile fabric in impermeable engineering projects?

Geotextile fabric is used to provide filtration, separation, and reinforcement in impermeable engineering projects. It prevents the mixing of soil layers, enhances drainage, and provides additional strength to the overall structure.

2: How does geotextile membrane contribute to waterproofing in construction projects?

Geotextile membrane acts as a waterproofing barrier by preventing the passage of water through the structure. It is commonly used to line landfills, reservoirs, and other structures to control water flow and prevent seepage.

3: Can geotextile fabric be used in conjunction with other impermeable materials?

Yes, geotextile fabric is often used in combination with impermeable materials like geomembranes to create a composite barrier system. This combination enhances the overall impermeability and stability of the structure.

4: How is the effectiveness of geotextile membrane tested in impermeable engineering projects?

The effectiveness of geotextile membrane is often tested through permeability and leakage tests. These tests assess the material's ability to resist water flow and ensure that it meets the required impermeability standards.

5: What considerations should be taken into account during the installation of geotextile materials in impermeable projects?

During installation, it's crucial to handle geotextile materials carefully to avoid damage. Proper overlap and seam integrity are essential for ensuring a continuous impermeable barrier. Additionally, site-specific conditions and engineering specifications must be adhered to for optimal performance.

Other related information for your reference:

https://hygeosynthetics.com/How-to-Implement-an-Effective-Liner-System-in-Landfill-Echo_87.html

503.webp)

759.webp)

628.webp)