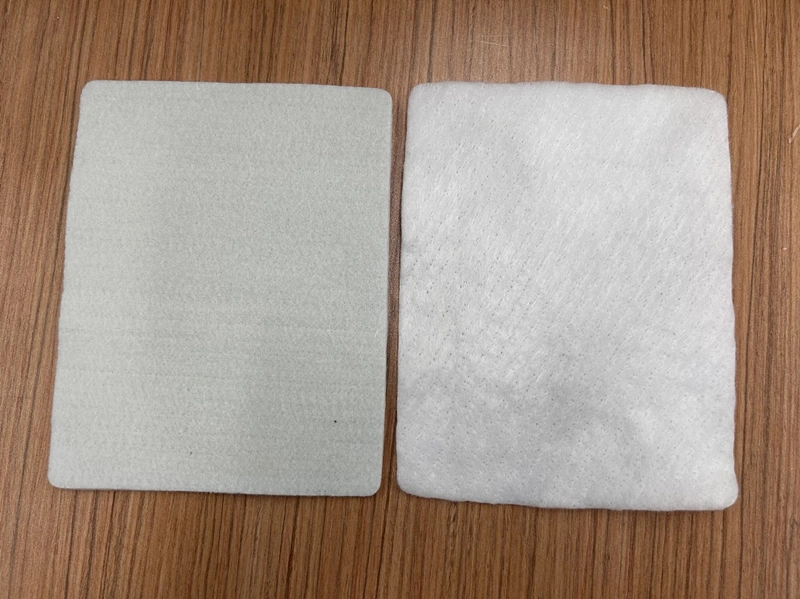

The filament nonwoven geotextile and short fiber we usually see are almost the same in color and appearance, and the feel is also very similar. How to distinguish between the two? Let's do a simple analysis below:

First, color and feel: Although both are white, the long-filament geotextile is whiter, glossier, and smoother when you look at it; the short-filament geotextile is darker in color and feels like it is mixed with hand. Cotton with impurities. Because filament geotextiles are made of melted polyester chips, and short filament geotextiles are made of other fiber materials, that is, "second-hand materials";

Second, the length of the wire drawing: As can be seen from the name, the wire drawing of the filament geotextile is longer, while the wire drawing of the short wire geotextile is shorter;

Third, it can also be distinguished from many aspects such as cost, raw materials, national standards, etc. I won’t go into details.

the difference between filament non-woven geotextiles and short fiber geotextiles

The two have similar functions in civil engineering, and both have the functions of reinforcement, reinforcement, filtering and drainage, barrier, protection, etc.

Let’s talk about the production process of filament geotextiles in detail based on the actual production of filament geotextiles in the workshop of Haoyang Environmental Co., Ltd.:

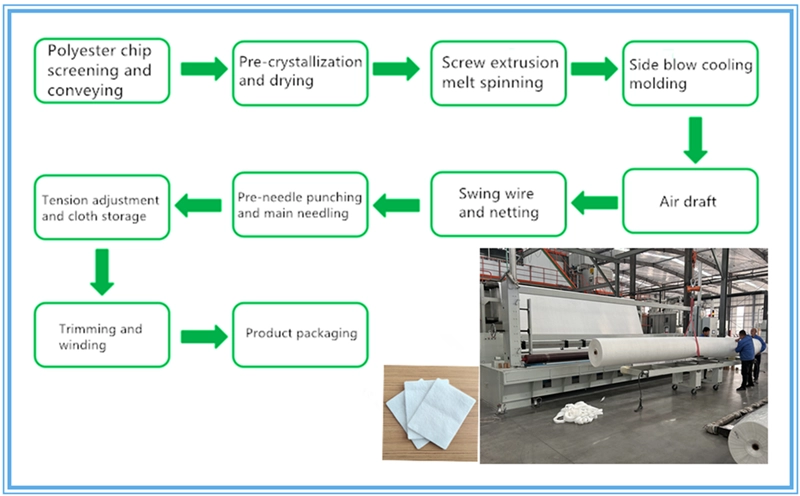

Production Process

production flow chart of filament non-woven geotextile

Detailed introduction of the production process

1. Slice screening and transportation:

The slicing ton bags are sent into the storage room by a forklift. The loader uses an electric hoist to lift the ton bags to the loading room on the second floor. The bag surface is cleaned to remove debris and dust, and then the ton bags are lifted to the material receiving room. Above the hopper, open the discharge port under the ton bag, and put the polyester slices into the receiving hopper for vibration screening. There are three outlets: large blocks, small blocks, and normal slices. The wet slicing storage tank on the roof is equipped with a material level meter. When the slicing material level reaches the upper limit, feeding will automatically stop. It is required to feed materials twice a day, once in the morning and once in the evening until full.

equipment for screening and transmitting polyester chips

2. Introduction to pre-crystallization and drying equipment

The wet slices come down from the wet slice storage tank on the roof through the rotary feeding valve, and fall quantitatively onto the pre-crystallization bed (ebullating bed). After the continuous action of the pulse air flow, they boil up and down and move forward continuously. After about 25 minutes of pre-crystallization, Fall into the main drying tower. The functions of the pre-crystallization bed are: first, to dry the wet slices and remove part of the moisture. The second is to heat and crystallize the wet slices to increase their softening point to above 210 degrees. After the dehumidified compressed air is dried in the drying tower for 4-6 hours, after the moisture content reaches below 30ppm, it is dropped into the screw extruder for spinning.

pre-crystallization and drying tower

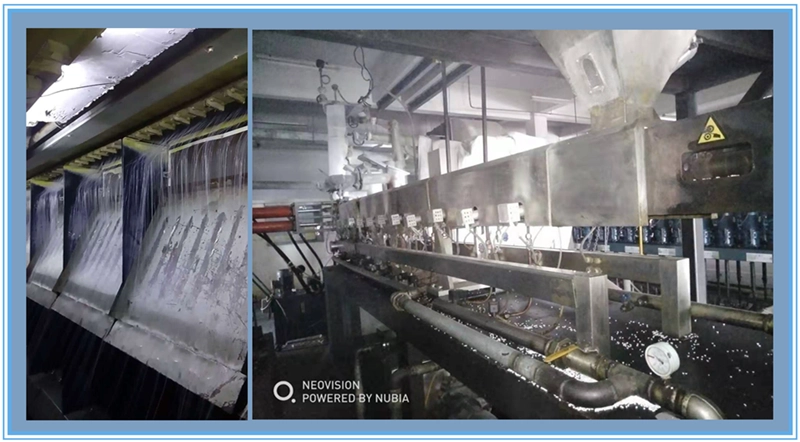

3. Introduction to spinning production and equipment

The slices dried in the drying tower are heated, extruded and melted by the extruder to become a melt. They are filtered by a pre-filter to remove impurities, and then are metered and output in equal amounts by a metering pump before entering the spinning assembly. This is a conventional spinning process. Our company's production equipment is the first domestic equipment that can directly produce non-woven fabrics from bottle flakes. On the basis of conventional production equipment, several additional filtration devices have been added. The first stage The filtration precision is 100μ, and the second-stage filtration precision is 25μ. It can remove most of the impurities in the bottle flakes to ensure that the cycle of the components is extended. Below the component is a spinneret. Generally, the spinneret of filament non-woven fabrics is designed with 34 holes and a hole diameter of 0.35mm. After exiting the spinneret, a thin flow of melt is formed, and after cooling, nascent fibers are formed.

screw extrusion melt spinning

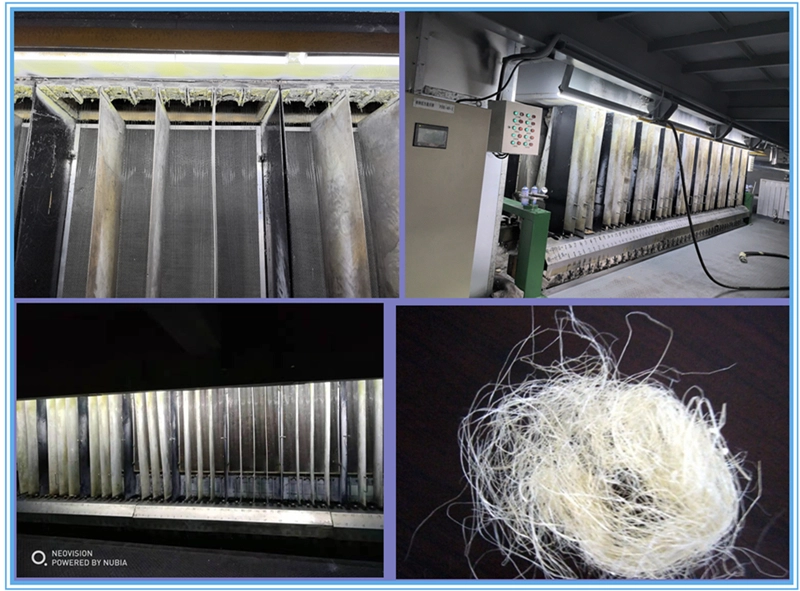

4. Side blow cooling and forming

Side blow cooling means blowing air from one side of the spinneret to cool the nascent fibers. The temperature drops from the spinning temperature to below the melting point, allowing them to solidify into filaments to facilitate drafting. The side blowing device is under the spinning box, that is, there is an air duct in the middle of the two rows of spinning, and it is blown out through the honeycomb panel. There is a filtering device inside the honeycomb panel to filter the wind and then blow it to the filament strips. cool down.

After the filament is cooled, the temperature reaches below the melting point of 260°C and solidifies into filament. Enter the stretcher to stretch.

side-blown cooling molding

5. Air draft:

There are two types of air flow drafting: one is pipe drafting and the other is slit drafting. Our company uses pipe drafting. The filament runs in a special pipe, and the air flow increases the running speed of the filament to achieve the purpose of drafting.

Pay attention to changes in drafting pressure. If the drafting pressure is not enough, it will cause insufficient fiber drafting and the strength of the geotextile will be low. When the wire mesh enters the pre-needle punching machine, it may not be able to withstand the stretching and break, resulting in Piling up nets, causing parking.

pipeline drafting, improve the speed of silk running

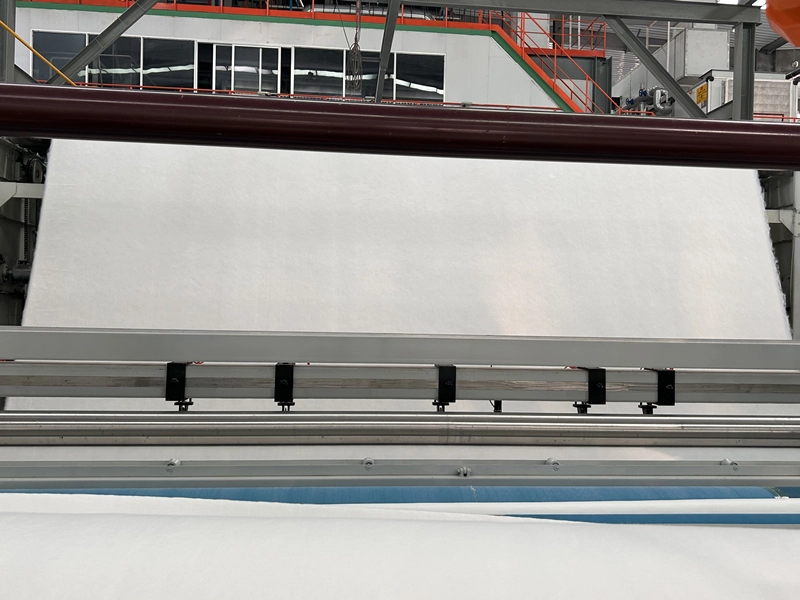

6. Swing wire laying net:

After the filament is drawn by the pipe drafter, it passes through a long drafting tube (length 3.3 meters) and goes down to the filament swing machine. Our pendulum machine is a plate-type pendulum machine. The two pendulum pendulum plates are set at a certain angle. During production, they swing left and right to spread the silk strips evenly on the mesh curtain. The mesh curtain of the mesh laying machine moves forward at a certain speed. Movement, the wire mesh is fed into the pre-needle punching machine for acupuncture.

swing wire laying net: The silk thread is quickly and evenly spread on the bottom net

7. Pre-acupuncture and main acupuncture:

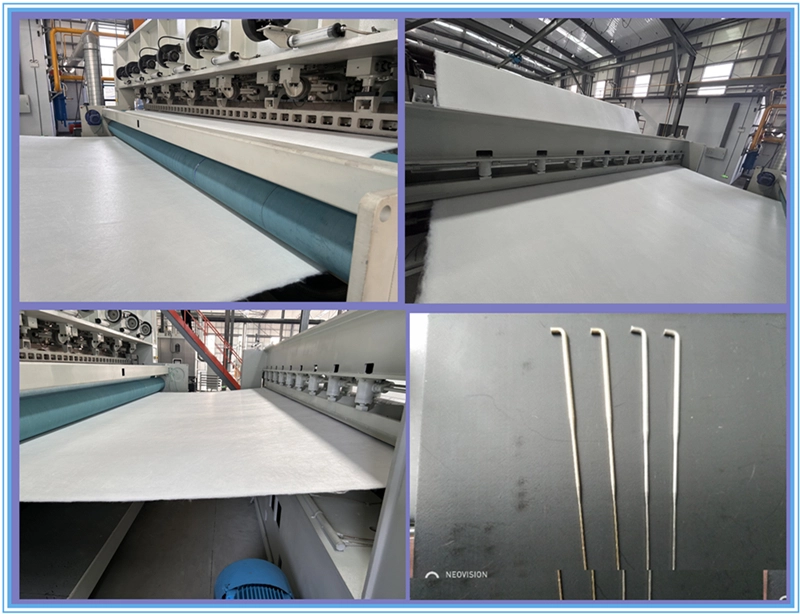

The pre-needle punching machine is a downward punching machine, with the needle punching from top to bottom; the main needle punching machine is a double-axis single needle plate needling machine, which is punched from bottom to top. The short fiber needle punching machine is a single-axis single needle plate needle punching machine, and the filament fiber needle punching machine is a double-axis single needle plate needling machine. The needle punching machine is mainly composed of needle plate, screen supporting plate, screen dialing plate, transmission part, oil circulation part and frame. The supporting plate of the pre-needle punching machine is on the bottom; the supporting plate of the main needling machine is on the top.

the upper left is pre-acupuncture, the upper right is main acupuncture, the lower left is pre-acupuncture and main acupuncture

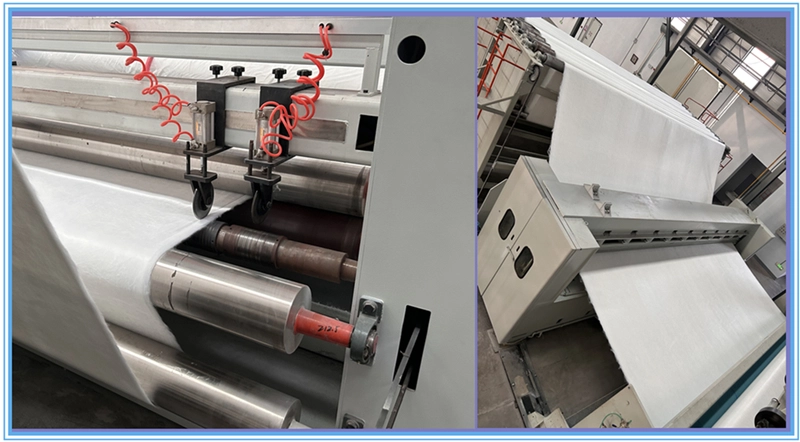

8. Cloth storage and tension adjustment

The tension frame of this production line is composed of 9 round rollers with a diameter of 150mm, 5 at the top and 4 at the bottom. During production, the lower rollers are pulled up by cloth. During unwinding, these 4 rollers run downward, and the unwinding is normal. After operation, these four rollers must move upward and return to their original positions. When the roller runs downward, the running speed is the process speed. When the roller runs upward, it reaches the process speed, returns to the original position, then stops, and resumes normal production.

several round rollers stretched out the cloth

9. Trimming and winding

The trimming and winding equipment is the same as that for short fibers. After the cloth passes through the tension frame, it passes through a pressure roller and then enters the winding machine. The winding machine is a friction type, that is, the friction between the two rollers under the cloth roll and the cloth roll drives the cloth roll to run. The winding machine is equipped with one transverse cutter, which is an automatic cutter; it is equipped with 4 longitudinal cutters, which are mechanical pressure type.

cut the edges that do not meet the requirements, and then wrap into a roll.

10. Package and store

Packaging method: Plastic packaging, use a plastic tube on one side of the cloth roll into it, and then, on the cloth roll, play 4 packing belts, the packing belt is evenly distributed, and both sides are tied with cable ties.

Before the finished product is released from the warehouse, the grade must be verified by the material inspection room according to the national standards, test results and appearance test results.

The statistician must accurately record the grade, weight, length and volume of the product. After checking with the warehouse keeper, they can leave (enter) the warehouse and sign by both parties.

filaments packaging, storage and transportation

This is the specific production process of filament non-woven geotextiles, if you want to know more about filament non-woven geotextiles information, you can open the following link to visit.

https://hygeosynthetics.com/Filament-geotextile-reinforcement-subgrade-new-material-LS_25.html

https://hygeosynthetics.com/800g-per-sqm-weighted-filament-geotextile-for-roadbed-LS_12.html

https://hygeosynthetics.com/Green-filament-geotextile-suitable-for-highway-roadbed-laying-LS_9.html

https://hygeosynthetics.com/White-waterproof-filament-non-woven-geotextile-for-tunnel-LS_2.html

897.webp)

942.webp)

237.webp)